•

•

•

•

7.4.33 WARNING/ALARM 35, Option Fault

Cause

An option alarm is received. The alarm is option-specific. The most likely cause is a power-up or a communication fault.

7.4.34 WARNING/ALARM 36, Mains Failure

Cause

This warning/alarm is only active if the supply voltage to the drive is lost and parameter 14-10 Mains Failure is not set to [0] No Func-

tion.

Troubleshooting

Check the fuses to the drive and mains supply to the unit.

7.4.35 ALARM 37, Phase Imbalance

Cause

There is a current imbalance between the power units.

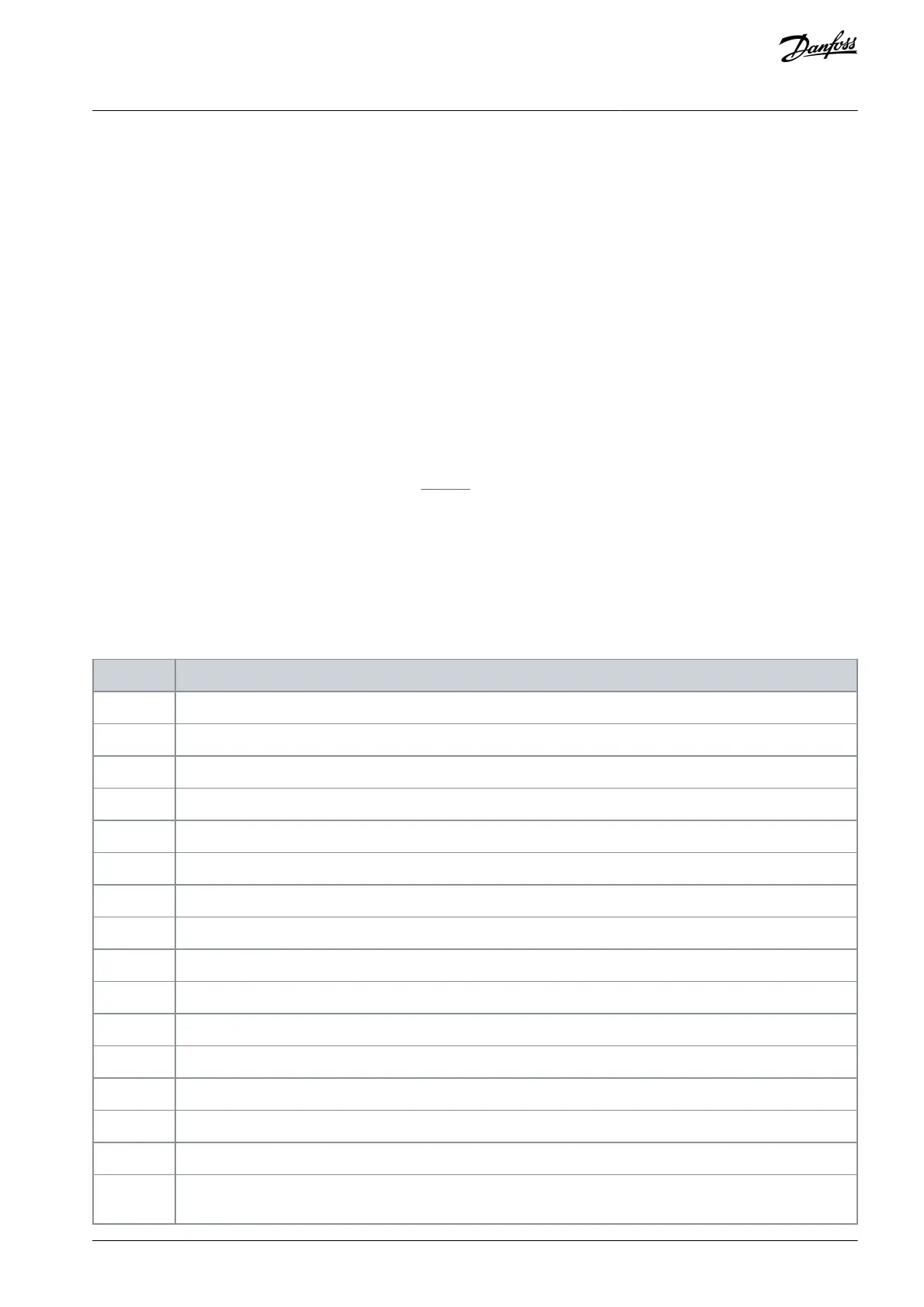

7.4.36 ALARM 38, Internal Fault

Cause

When an internal fault occurs, a code number defined in

Table 28 is shown.

Troubleshooting

Cycle power.

Check that the option is properly installed.

Check for loose or missing wiring.

It may be necessary to contact the Danfoss supplier or service department. Note the code number for further troubleshooting direc-

tions.

Table 28: Internal Fault Codes

The serial port cannot be initialized. Contact the Danfoss supplier or Danfoss service department.

The power EEPROM data is defective or too old. Replace the power card.

Internal fault. Contact the Danfoss supplier or Danfoss service department.

Parameter value outside of minimum/maximum limits.

Internal fault. Contact the Danfoss supplier or Danfoss service department.

The option software in slot A is too old.

The option software in slot B is too old.

The option software in slot C1 is too old.

The option software in slot A is not supported/allowed.

The option software in slot B is not supported/ allowed.

The option software in slot C1 is not supported/ allowed.

Internal fault. Contact the Danfoss supplier or Danfoss service department.

Hardware reset of digital signal processor.

Motor-derived parameters not transferred correctly to the digital signal processor.

Power data not transferred correctly at power-up to the digital signal processor.

The digital signal processor has received too many unknown SPI telegrams. The AC drive also uses this fault code if

the MCO does not power up correctly. This situation can occur due to poor EMC protection or improper grounding.

AQ267037727118en-000101 / 130R0300 | 51Danfoss A/S © 2021.01

Maintenance, Diagnostics, and

Troubleshooting

VLT® AutomationDrive FC 301/FC 302

Operating Guide

Loading...

Loading...