VLT

®

AutomationDrive EtherNet/IP

MG.90.Jx.02 ver. 5

th

September 2007 – VLT is a registered Danfoss trademark 52

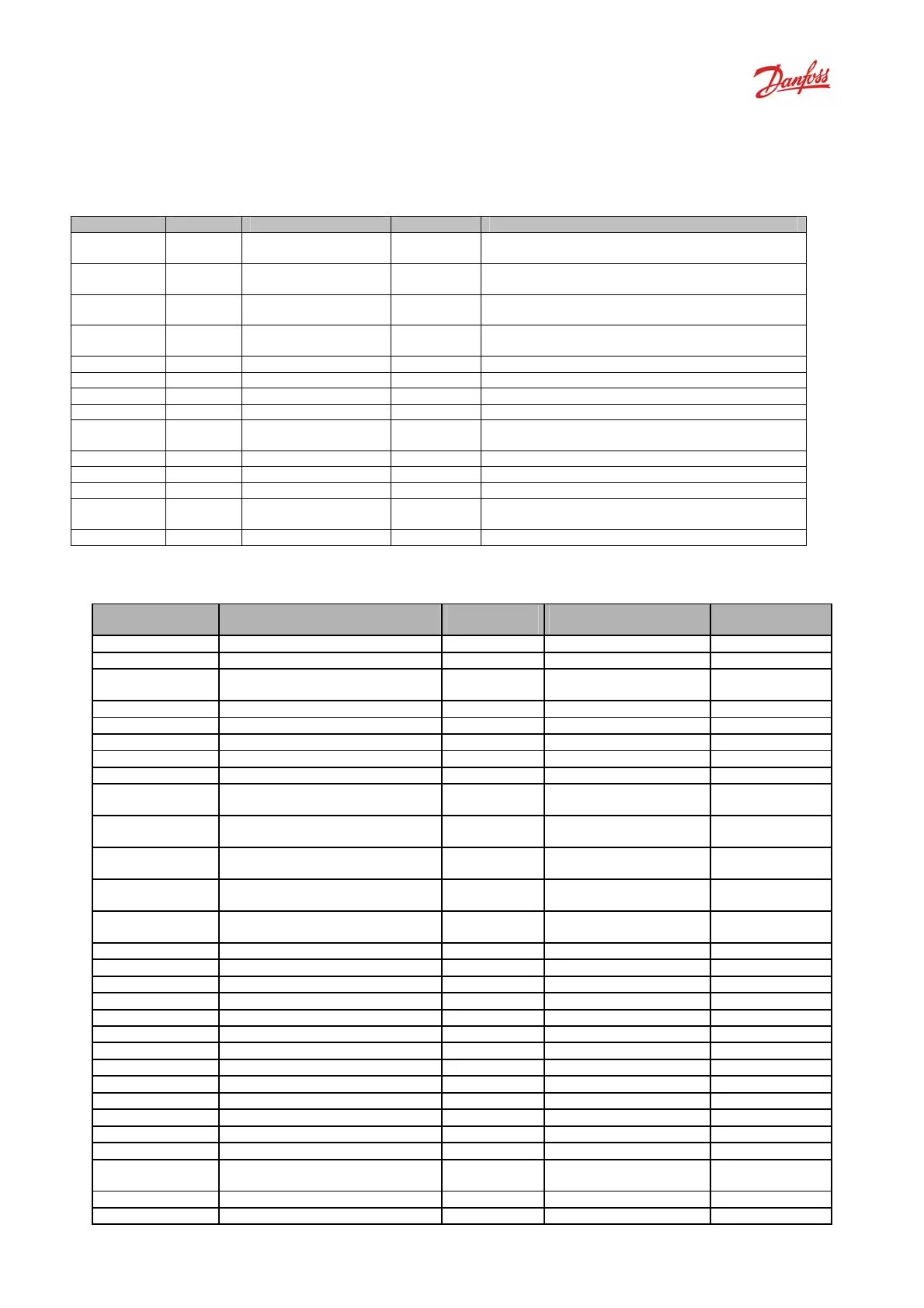

Class ID 0x29 Control Supervisor Object

Instance Attributes

Attribute Access Name Data Type Description

1 Get Number of Attributes

supported

USINT 12

2 Get List of supported

Attributes

Array of

USINT

3,4,4,5,6,7,8,9,10,11,12,13,15

3 Get/Set Run 1 (forward) Boolean FC CTW Bit 6 = Run1 XOR Run2

FC CTW Bit15 = 0

4 Get/Set Run 2 (reverse) Boolean FC CTW Bit 6 = Run1 XOR Run2

FC CTW Bit15 = 1

5 Get/Set Network Control Boolean Parameter 12-32 value written from option

6 Get State USINT The state of the CIP state-machine

7 Get Running 1 Boolean Run1 AND bit 11 in FC STW

8 Get Running 2 Boolean Run2 AND bit 11 in FC STW

9 Get Ready Boolean STATE_ENABLED or STATE_STOPPING or

STATE_FAULT_STOP from state-machine

10 Get Faulted Boolean Bit 3 in FC STW

11 Get Warning Boolean Bit 7 in FC STW

12 Get/Set Fault reset Boolean Bit 7 in FC CTW

13 Get Fault Code UINT Mapping of par. 16-90 Alarm Word to CIP

specific fault codes

15 Get Control from net Boolean Parameter 12-31 value written from option

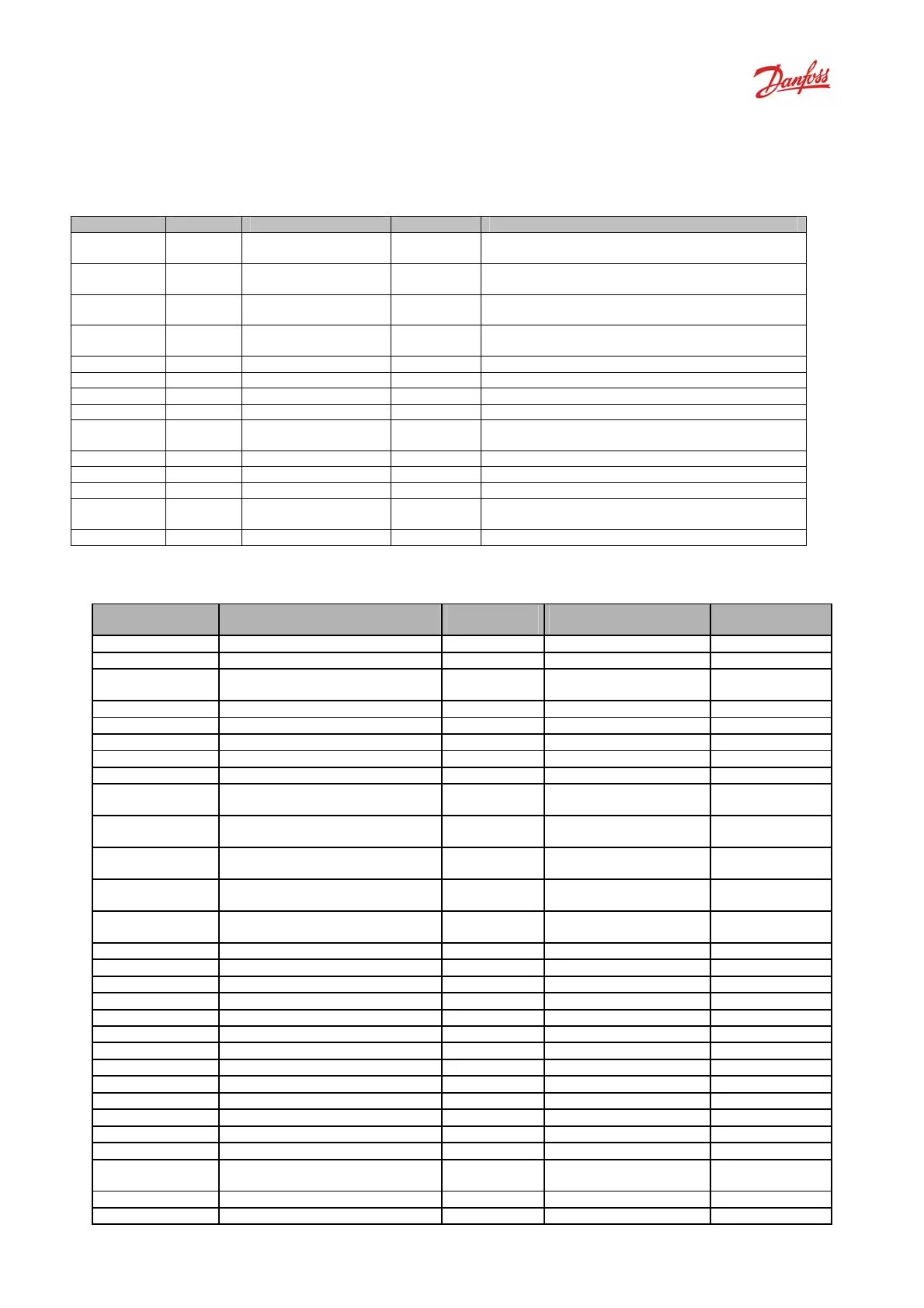

Attribute 13 “Fault Code”

CIP Malfunction

Code

Meaning VLT-Code

Alarmword

CIP Malfunction

Meaning

CIP

Classification

0 No alarm 0000 0000 No fault -

0 unused 0000 0001 No fault -

4210 Drive over temperature 0000 0002 Excessive Device

Temperature

mar

2240 Earth fault 0000 0004 Short to earth mau

0 unused 0000 0008 No fault -

8100 Controlword timeout 0000 0010 Communication mir

2310 Overcurrent 0000 0020 Continuous Overcurrent mau

8302 Torque limit 0000 0040 Torque limiting mar

4310 Motor thermistor 0000 0080 Excess Drive

Temperature

mar

4310 Motor ETR over temp 0000 0100 Excess Drive

Temperature

mar

2311 Inverter overloaded 0000 0200 Current inside the

device, No. 1

mar

3220 DC Link undervoltage 0000 0400 Undervoltage inside the

Device

mar

3210 DC Link overvoltage 0000 0800 Overvoltage inside the

device

mar

2130 Short circuiting 0000 1000 Short Circuit mau

2213 Inrush fault 0000 2000 Overcurr. during startup mar

3130 Mains phase loss 0000 4000 Phase Failure mau

5210 AMT fail 0000 8000 Measurement Circuit mir

1000 Live zero fault 0001 0000 General fault mar

6100 Internal fault 0002 0000 Internal software fault mau

7110 Brake resistor power limit 0004 0000 Brake Chopper mau

3300 Motor phase U missing 0008 0000 Output voltage mau

3300 Motor phase V missing 0010 0000 Output voltage mau

3300 Motor phase W missing 0020 0000 Output voltage mau

8100 Fieldbus Comm. fault 0040 0000 Communication mir

5112 24V supply fault 0080 0000 +24V Power supply mau

3100 Mains failure 0100 0000 Mains Voltage mar

5110 1,8V supply fault 0200 0000 Low voltage power

supp.

mau

7110 Brake resist. short circ. 0400 0000 Brake chopper mar

7110 Brake chopper fault 0800 0000 Brake chopper mar

Loading...

Loading...