Operating instructions, SM-110/-111

Servicing and maintenance

40

8

5. Check lateral runout before test run. If necessary, open the screw and turn

the grinding wheel a little further.

6. Repeat the process until the grinding wheel runs, if necessary dress the

grinding wheel. (see 8.2 Dressing the grinding wheel).

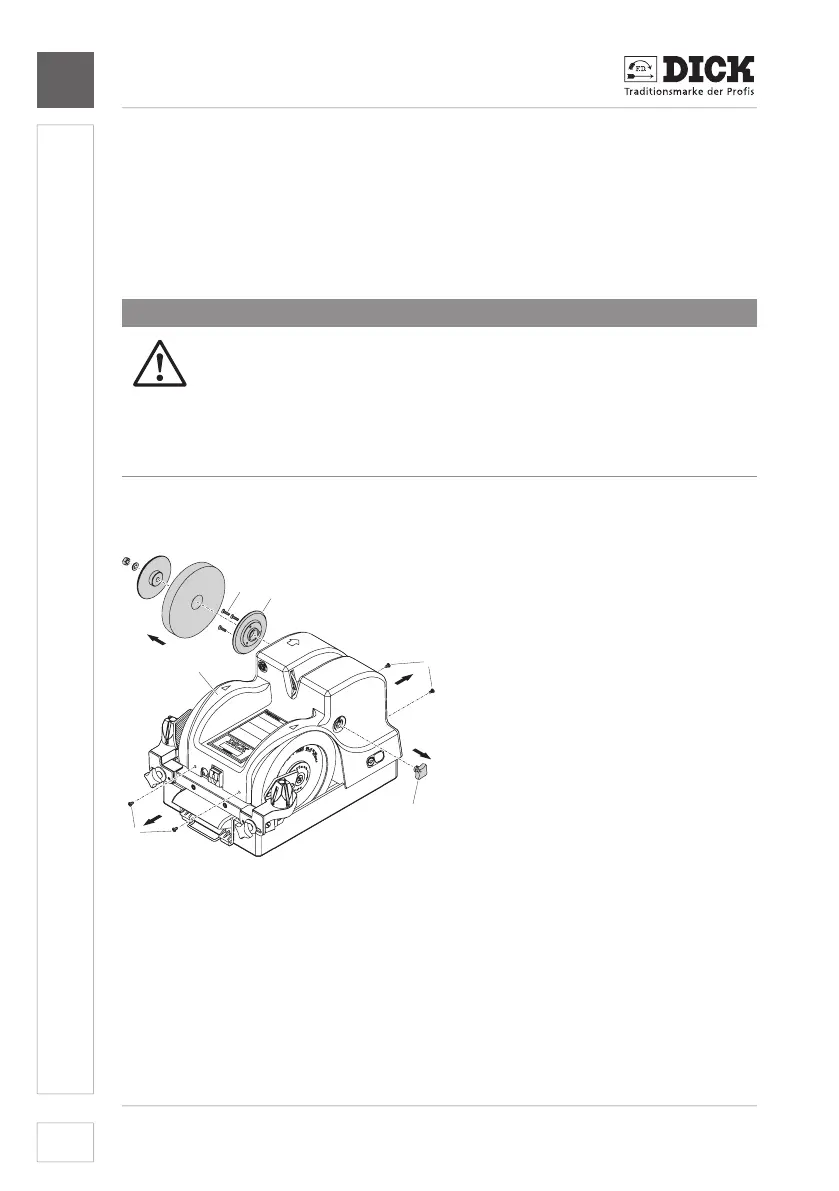

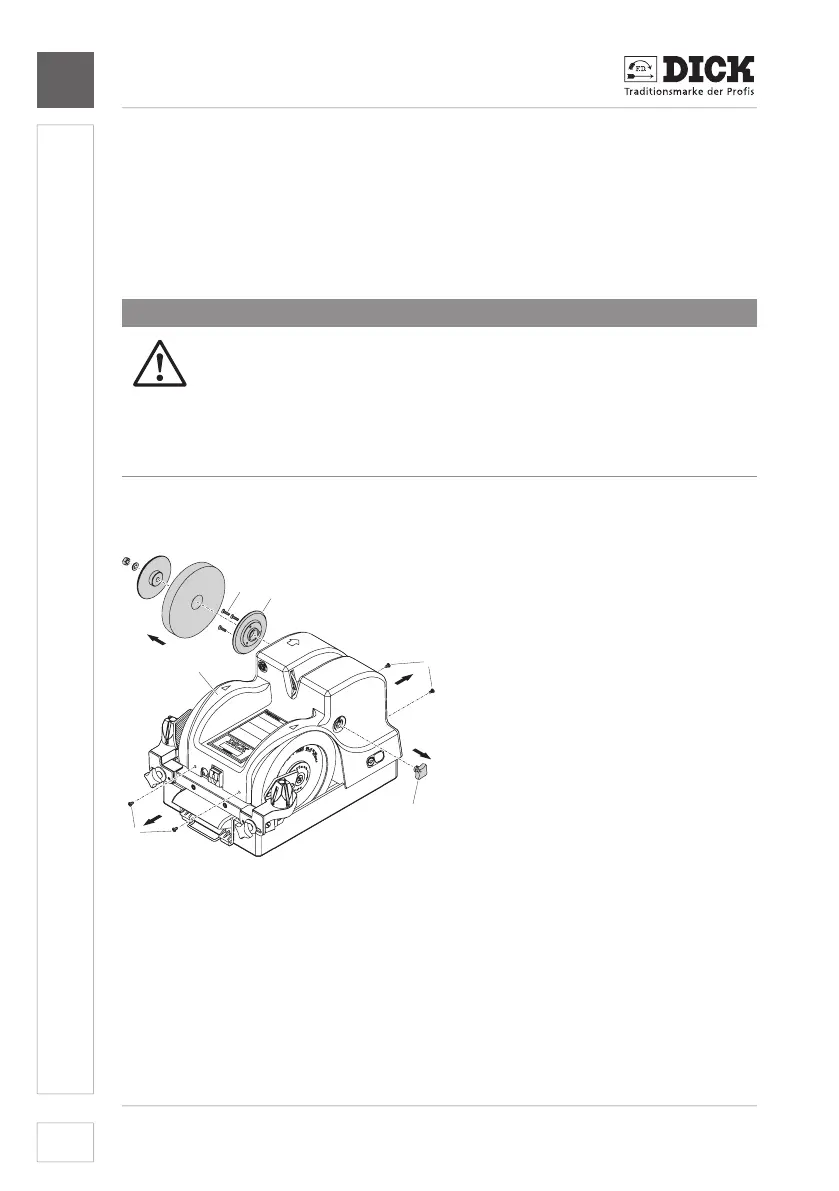

8.5 Remove the honing wheels

Damaged honing wheels (e.g. breakage, cracks, nicks) must be replaced.

CAUTION

RISK OF INJURY FROM ROTATING MACHINE PARTS

If the machine is accidentally switched on during maintenance

work, there is a risk of injury due to rotating machine parts.

➾ Always pull the mains plug before carrying out any mainte-

nance work.

1. Pull the mains plug.

2. SM-110: Continue with step 5

1

2

3

4

4

5

Only for SM-111

[20-1] Countersunk screws

[20-2]Flangeincl.ttingscrew

[20-3] Star handle

SM-110 and SM-111

[20-4] Screws on the end faces

of the housing

[20-5] Housing

Image 20 – Remove the honing wheels

Only for SM-111:

3. Remove polishing wheel (see 8.7 Replacing the polishing wheel (only for

SM-111)).

4. In addition, unscrew the three countersunk screws [20-1] with the

enclosedPhillipsscrewdriverandremovetheange[20-2]incl.thetting

screw. Pull off the star handle [20-3].

Loading...

Loading...