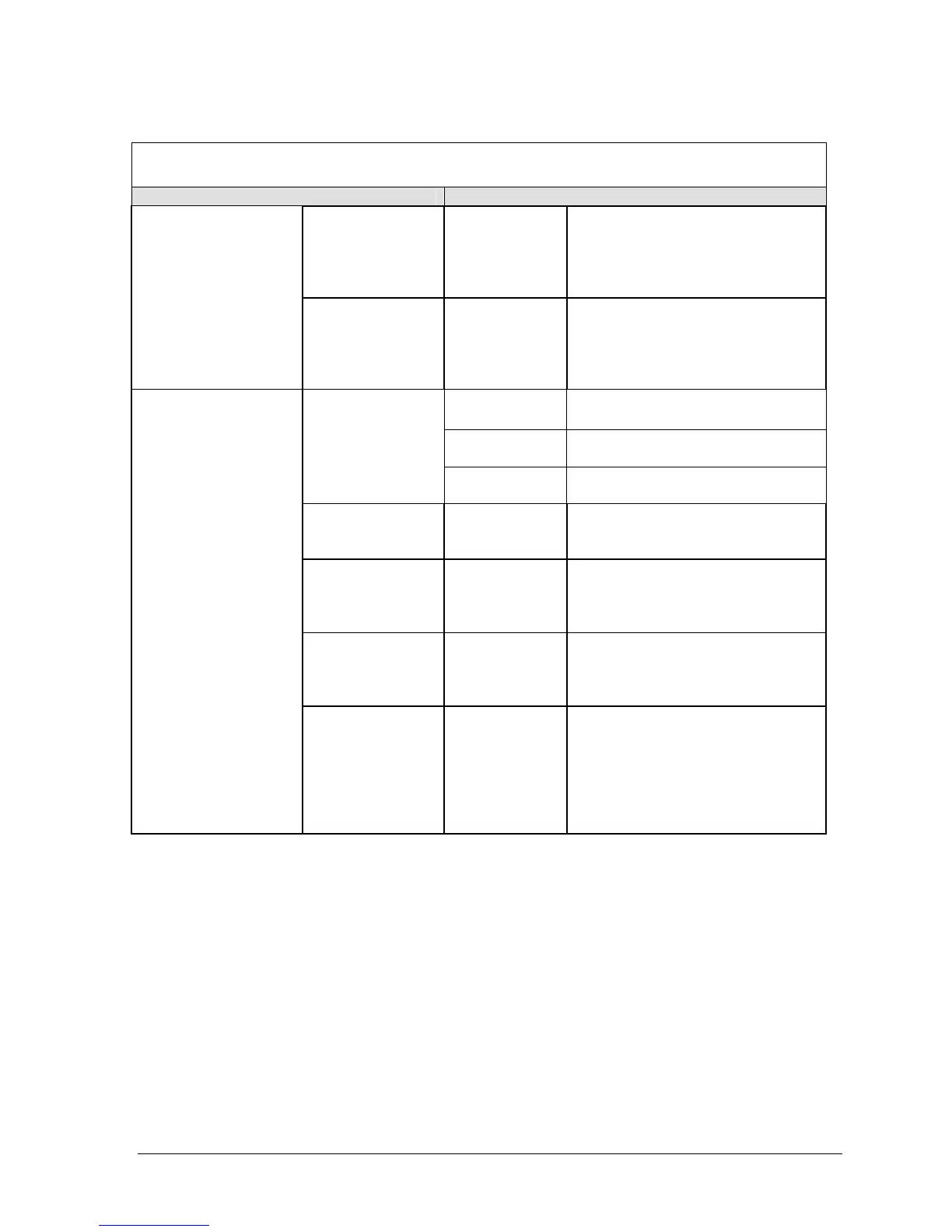

Chapter 5: Troubleshooting

Operation Manual: Evolution Series

Mechanical

PROBLEM POSSIBLE SOLUTION

Idler wheels Idler wheels

Inspect the idler wheels especially

the bearings for any sign of wear.

Lubricate the bearings if

necessary.

Replace the idler wheel assembly.

Pulleys Pulleys

Inspect the pulleys for any cracks

that may cause the setscrews to

loosen up. This will cause the

pulley to rotate around the

spindle shaft.

Drive belts

tension

Check drive belts tension.

Adjust if necessary.

Lubrication

Lubricate the drive belts with

vacuum grease.

Drive belts

Drive belts

Replace the drive belts if

necessary.

Drive motor Brushes

Check the drive motor’s

conductive brushes for wear.

Replace the brushes if necessary.

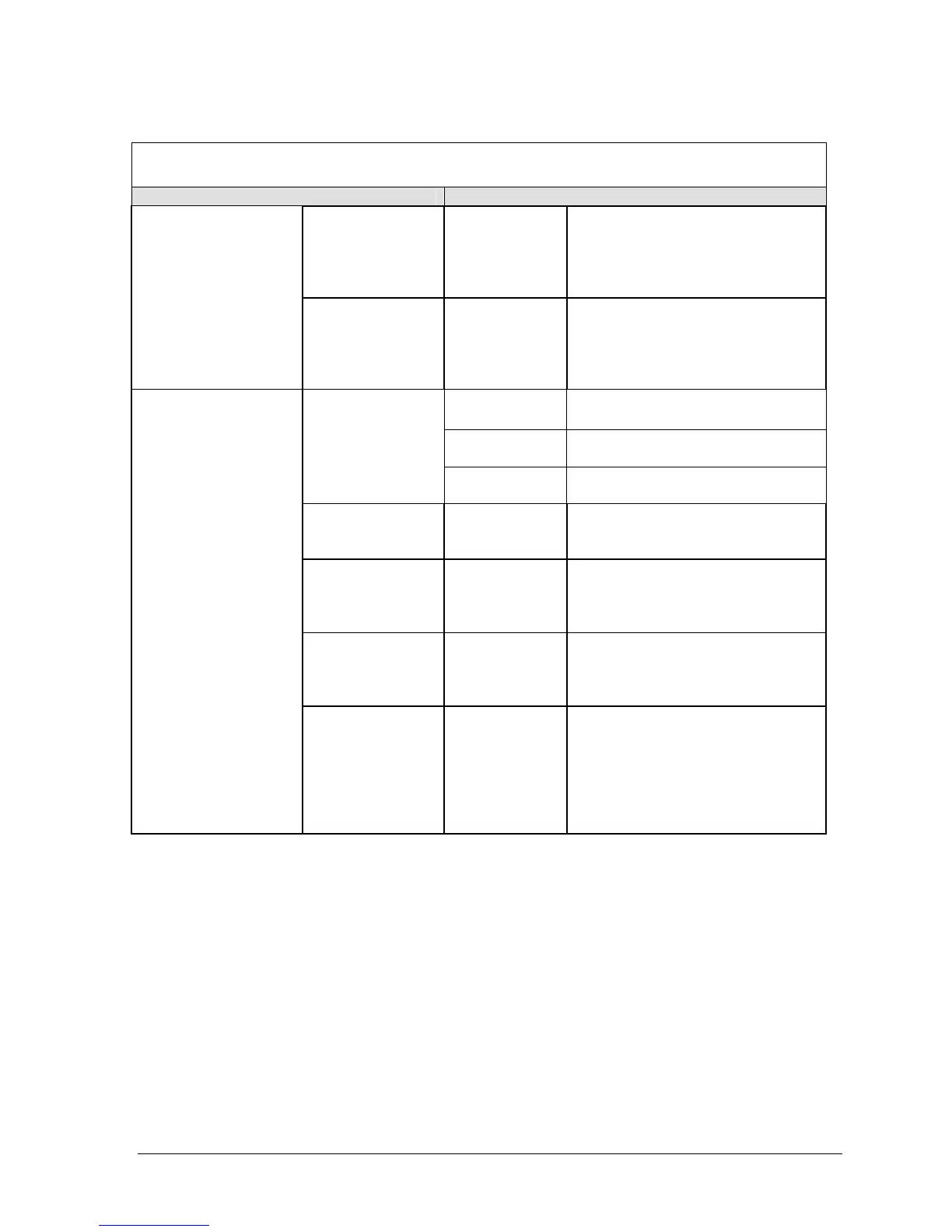

Idler wheels Idler wheels

Inspect idler wheels especially

bearings for any sign of wear.

Lubricate bearings if necessary.

Replace idler wheel assembly.

Other

equipment

Instruments

and

equipment

Make sure that there are no units

that can produce excessive

vibration when they are turned on

(filtration systems, shakers, etc.).

EXCESS VIBRATION

Pulleys Pulleys

Inspect the pulleys for any cracks

that may cause the setscrews to

loosen up (this will cause the

pulley to rotate around the

spindle shaft).

Replace cracked or defective

pulleys.

Loading...

Loading...