D O D T E C H N O L O G I E S , I

Rev 12.109

Page 21

Chapter 6 - Maintenance

6.1 Micro Secure Digital (SD) Card replacement

See Appendix F for detailed information on the contents of the SD Card.

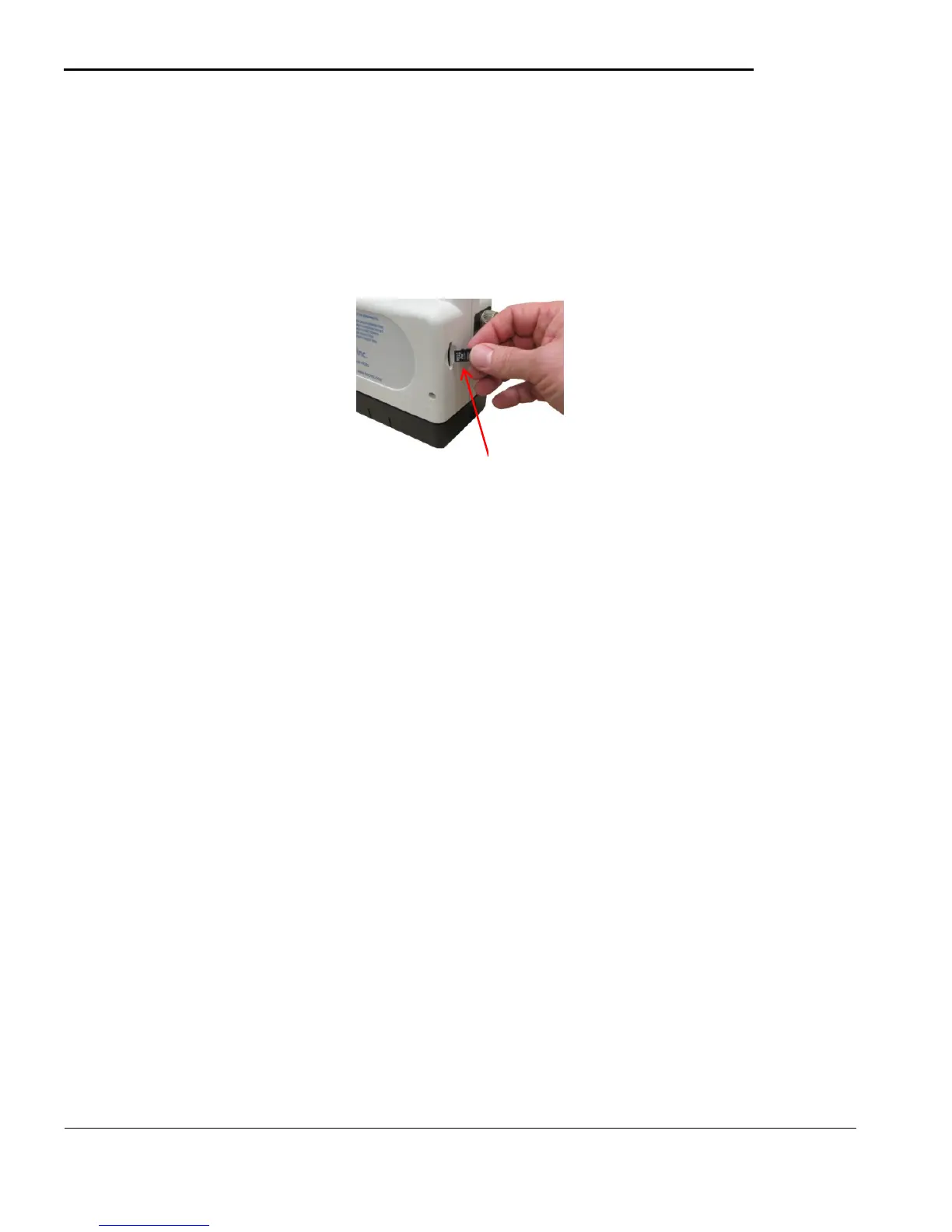

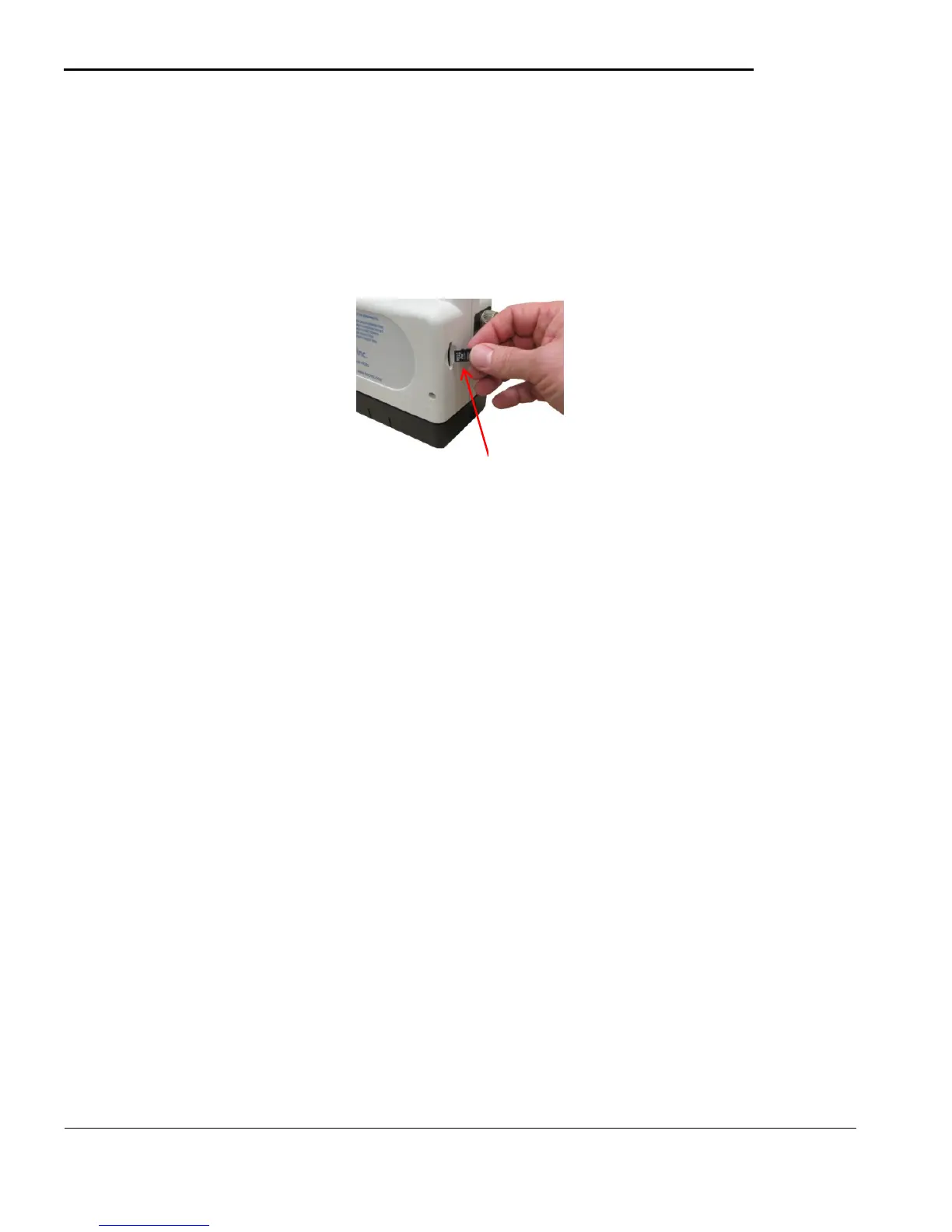

Install the MicroSD card with the 8 pin gold edge connector facing to the left of the machine when viewing

from the back – see Figure 6.1

Figure 6.1

6.2 Routine Maintenance

Reliable operation of the CLPX monitor requires that the unit be maintained in good working order

and that the sample input path and tape transport area are clean. Regularly inspect the CLPX

monitor for proper operation and damage. Establish a schedule for cleaning the CLPX monitor

based or usage and the nature of the sampling environment and clean as needed according to the

cleaning instructions below. If you have any questions or concerns, contact DOD Technologies.

6.2.a Inspection of the CLPX

1. Inspect the CLPX monitor for damage such as cracks to the housings or loose or missing

components.

2. Check the tape door release and lock for proper operation. Check the tape door for damage.

3. Check the sample input path for damage or for missing components.

4. The inlet tube must be properly seated in the optics block and flush with the end of the cover

tube.

5. Start the unit and check for any performance issues such as excessive or unusual noise, erratic

operation, or problems with the display. If any damage is found, remove the unit from service

and tag for repair by authorized personnel.

6.2.b Cleaning the CLPX

Cleaning of the CLPX portable gas monitor is essential to maintain reliable and accurate

measurements. Problems with calibration may be an indication of the need for cleaning. Dust and

contaminants can build up and interfere with the sensitive optics. Most routine cleaning of the CLPX

monitor involves removal of tape dust build up and cleaning of the sample input path. Additional

cleaning may be required in dusty environments or in some atmospheres, such as those where MDI is

being measured, which may contain wet or sticky aerosols that can build up in the sample input path.

Establish a cleaning schedule that is suitable for the conditions where the CLPX monitor will be used.

Wear powder-free surgical gloves (or equivalent) when cleaning the interior surfaces and

mechanism to avoid contact with the paper tape dust and other contaminants and when handling

pieces of the paper tape in the course of these instructions.

Cleaning the CLPX monitor may require the use of pressurized air. For some cleaning, a rubber

8 pin gold edge connectors

on this side

Loading...

Loading...