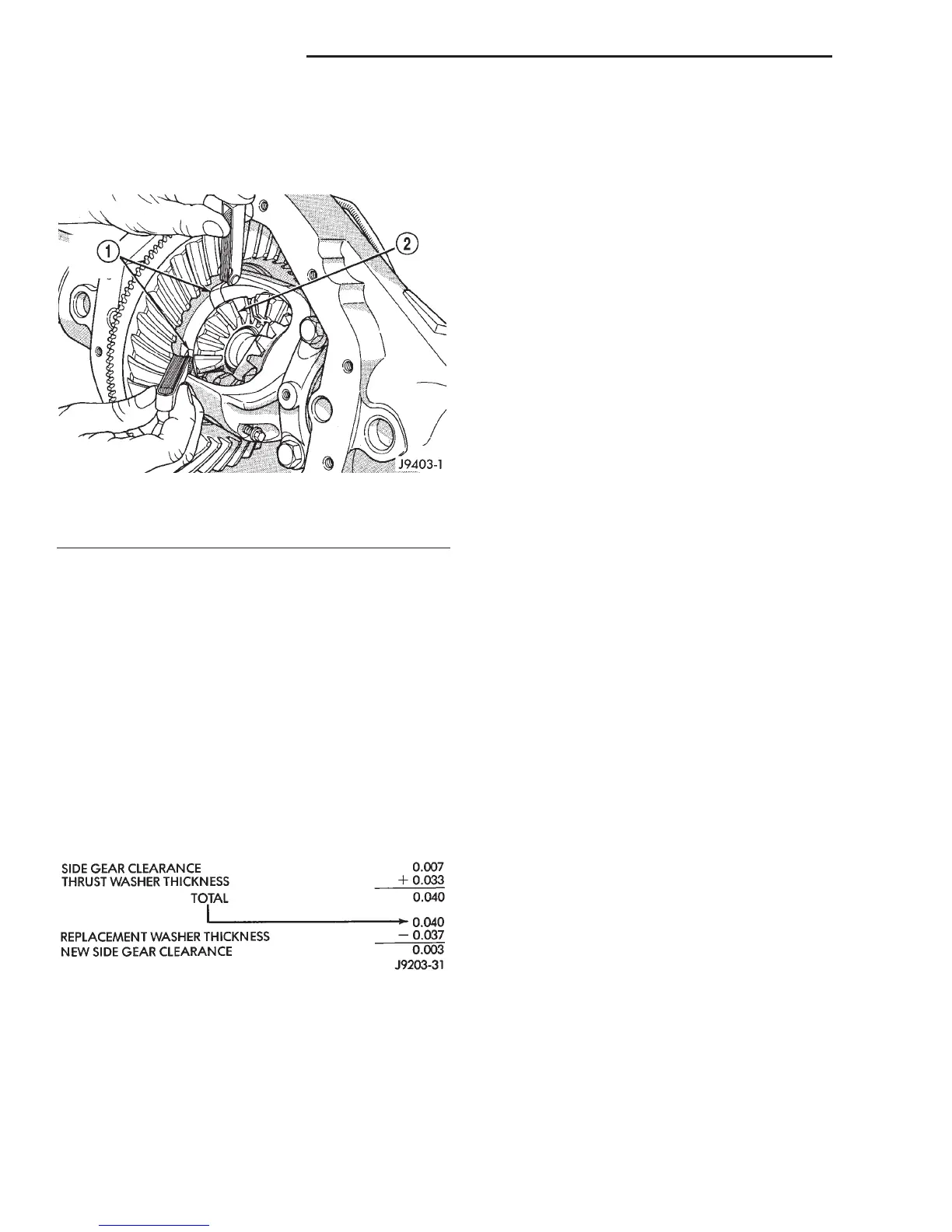

(2) Measure each side gear clearance. Insert a

matched pair of feeler gauge blades between the gear

and differential housing on opposite sides of the hub

(Fig. 82).

(3) If side gear clearances is no more than 0.005

inch. Determine if the axle shaft is contacting the

pinion mate shaft. Do not remove the feeler

gauges, inspect the axle shaft with the feeler

gauge inserted behind the side gear. If the end of

the axle shaft is not contacting the pinion mate

shaft, the side gear clearance is acceptable.

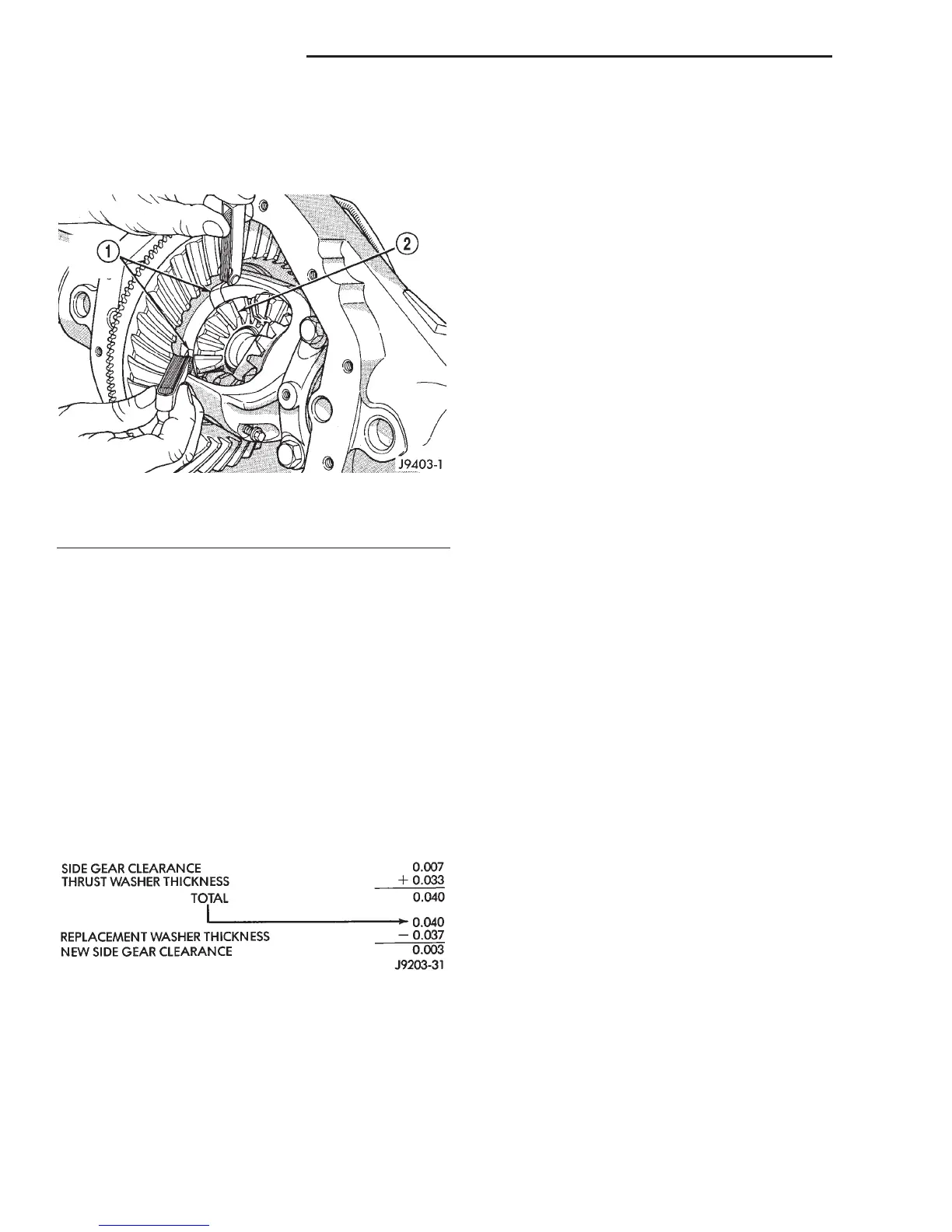

(4) If clearance is more than 0.005 inch (axle shaft

not contacting mate shaft), record the side gear clear-

ance. Remove the thrust washer and measure its

thickness with a micrometer. Add the washer thick-

ness to the recorded side gear clearance. The sum of

gear clearance and washer thickness will determine

required thickness of replacement thrust washer

(Fig. 83).

In some cases, the end of the axle shaft will move

and contact the mate shaft when the feeler gauge is

inserted. The C-lock is preventing the side gear from

sliding on the axle shaft.

(5) If there is no side gear clearance, remove the

C-lock from the axle shaft. Use a micrometer to mea-

sure the thrust washer thickness. Record the thick-

ness and re-install the thrust washer. Assemble the

differential case without the C-lock installed and re-

measure the side gear clearance.

(6) Compare both clearance measurements. If the

difference is less than 0.012 inch (0.305 mm), add

clearance recorded when the C-lock was installed to

thrust washer thickness measured. The sum will

determine the required thickness of the replacement

thrust washer.

(7) If clearance is 0.012 inch (0.305 mm) or

greater, both side gears must be replaced (matched

set) and the clearance measurements repeated.

(8) If clearance (above) continues to be 0.012 inch

(0.305 mm) or greater, the case must be replaced.

SPECIFICATIONS

8 1/4 INCH AXLE

Axle Type ............... Semi-floating, hypoid

Lubricant ...................... SAE80W-90

Lube Capacity ................ 2.22 L (4.7 pts.)

Trac-Lok Additive ............... 148ml(5oz.)

Axle Ratio .................... 3.21, 3.55, 3.92

Differential

Case Clearance ............. 0.12 mm (0.005 in.)

Case Flange Runout ........ 0.076 mm (0.003 in.)

Ring Gear

Diameter .................. 20.95 cm (8.25 in.)

Backlash ......... 0.12-0.20 mm (0.005-0.008 in.)

Runout .................. 0.127 mm (0.005 in.)

Pinion Bearing Preload

Original ................ 1-2N·m(10-20 in.lbs.)

New................... 2-5N·m(15-35 in.lbs.)

9 1/4 INCH AXLE

Axle Type ............... Semi-floating, hypoid

Lubricant ...................... SAE75W-90

Lube Capacity ................ 2.32 L (4.9 pts.)

Trac-lok Additive ................ 148ml(5oz.)

Axle Ratio .................... 3.21, 3.55, 3.92

Differential

Case Flange Runout ........ 0.076 mm (0.003 in.)

Ring gear

Diameter .................. 23.50 cm (9.25 in.)

Backlash ......... 0.12-0.20 mm (0.005-0.008 in.)

Runout .................. 0.127 mm (0.005 in.)

Pinion Bearing Preload

Original ................ 1-2N·m(10-20 in.lbs.)

New.................. 2–5N·m(15–35 in. lbs.)

Fig. 82 Side Gear Clearance Measurement

1 – FEELER GAUGE BLADES

2 – SIDE GEAR

Fig. 83 Side Gear Calculations

3 - 98 8 1/4 AND 9 1/4 AXLE DN

ADJUSTMENTS (Continued)

Loading...

Loading...