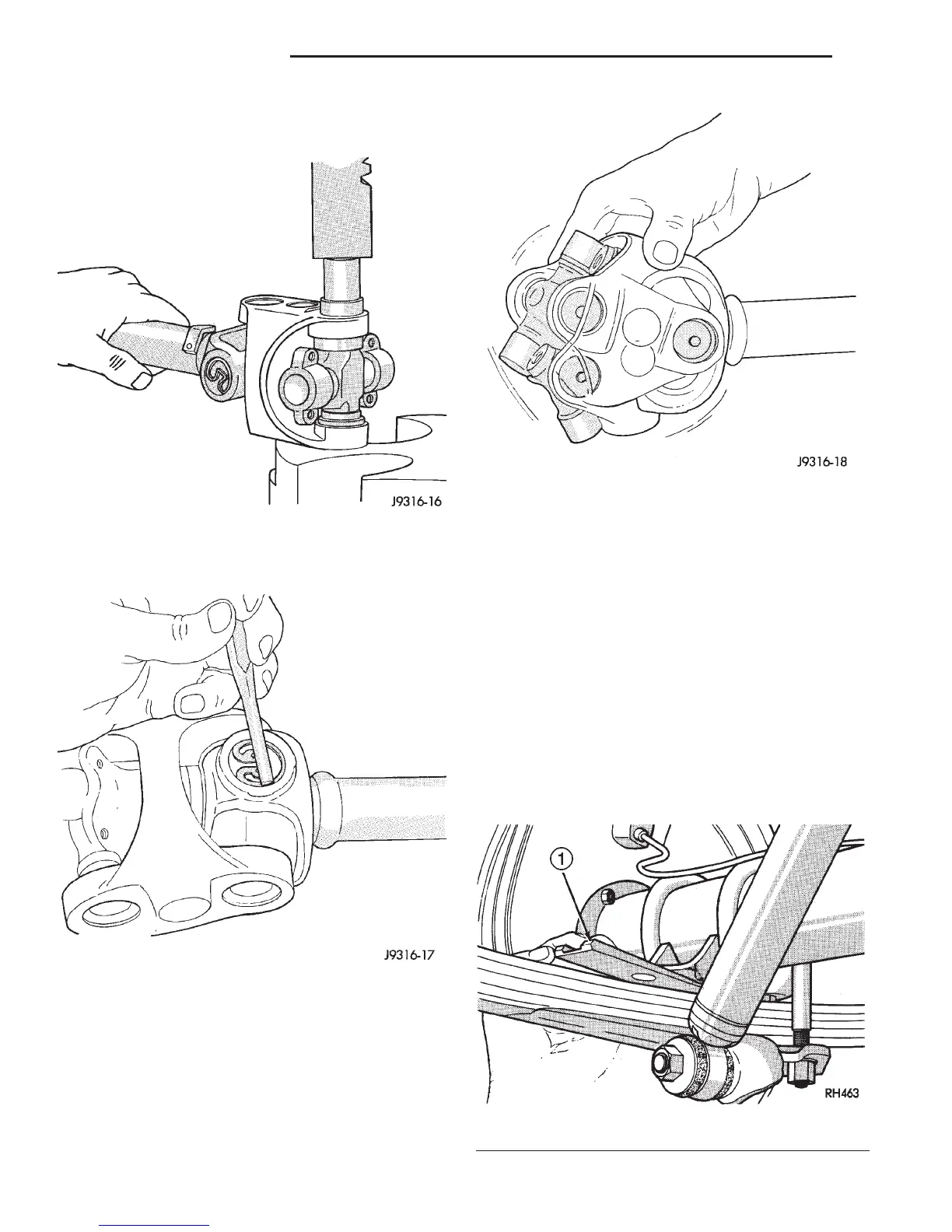

(11) Press the remaining two bearing caps into

place and install snap rings (Fig. 34).

(12) Tap the snap rings to allow them to seat into

the grooves (Fig. 35).

(13) Check for proper assembly. Flex the joint

beyond center, it should snap over-center in both

directions when correctly assembled (Fig. 36).

(14) Install the propeller shaft.

CLEANING AND INSPECTION

PROPELLER SHAFT

(1) Clean all universal joint bores with cleaning

solvent and a wire brush.

(2) Inspect the yokes for distortion, cracks, and

worn bearing cap bores.

ADJUSTMENTS

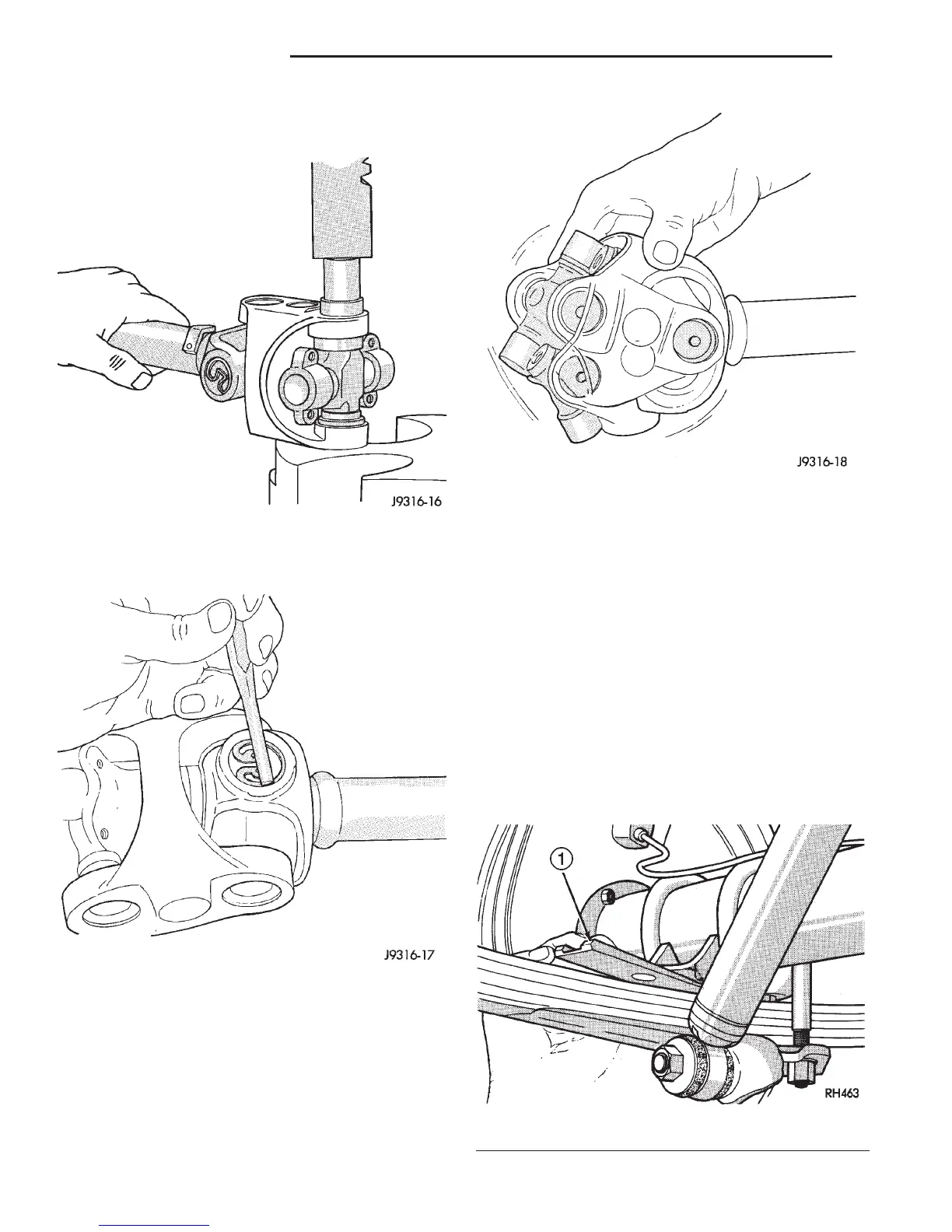

REAR AXLE PINION INPUT ANGLE

Adjust the rear axle pinion input angle on vehicles

equipped with leaf springs with tapered shims (Fig.

37). Install tapered shims between the springs and

axle pad to correct the angle. Refer to Group 2, Sus-

pension, for additional information.

Fig. 34 Press In Bearing Cap

Fig. 35 Seat Snap Rings In Groove

Fig. 36 Check Assembly

Fig. 37 Pinion Angle Adjustment at Leaf Springs

1 – WEDGE

3 - 16 PROPELLER SHAFTS DN

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...