MAINTENANCE SECTION 5

Page 21

DRESSTA OM560C99/1E

BRAKES

VENTING THE SYSTEM

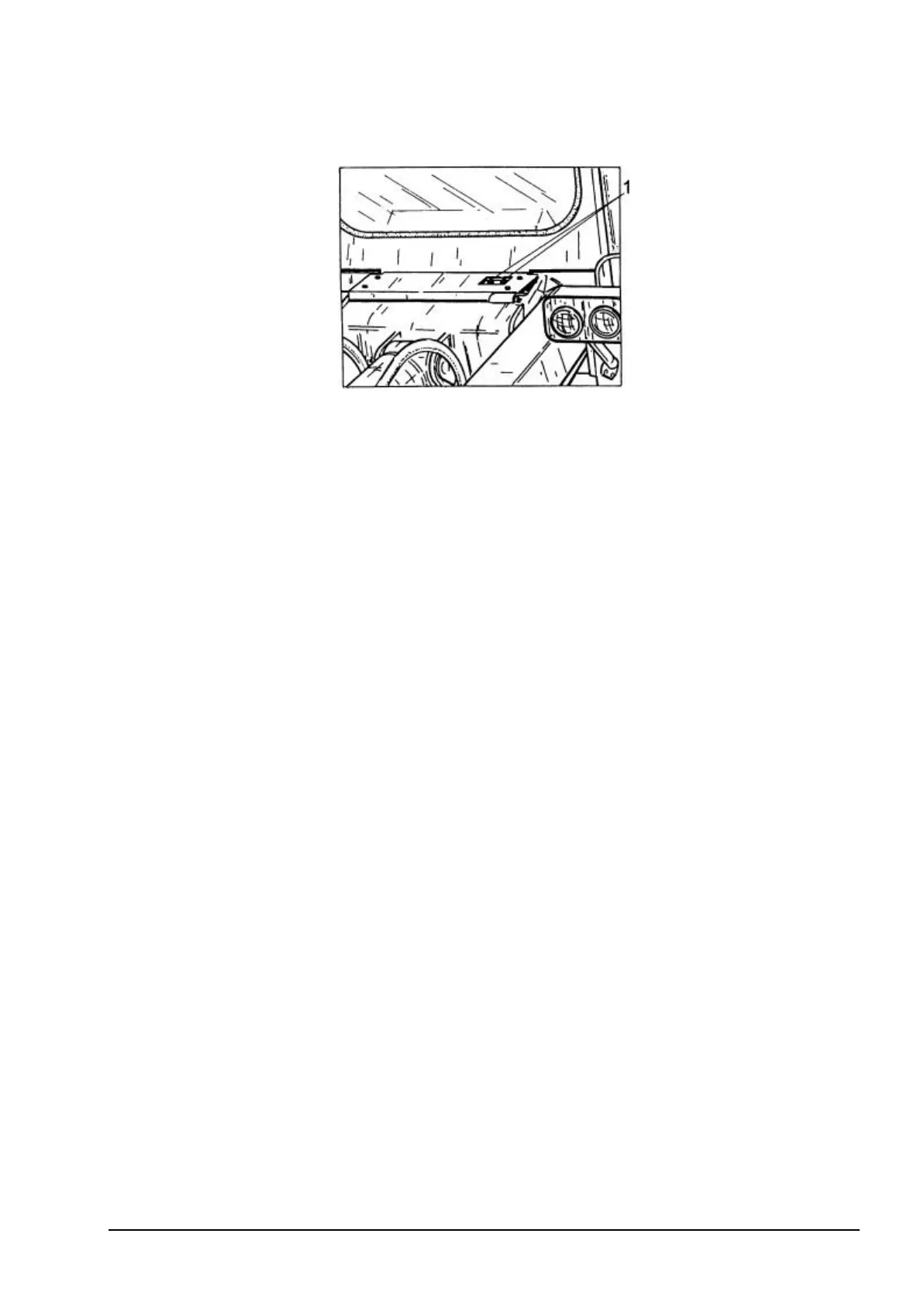

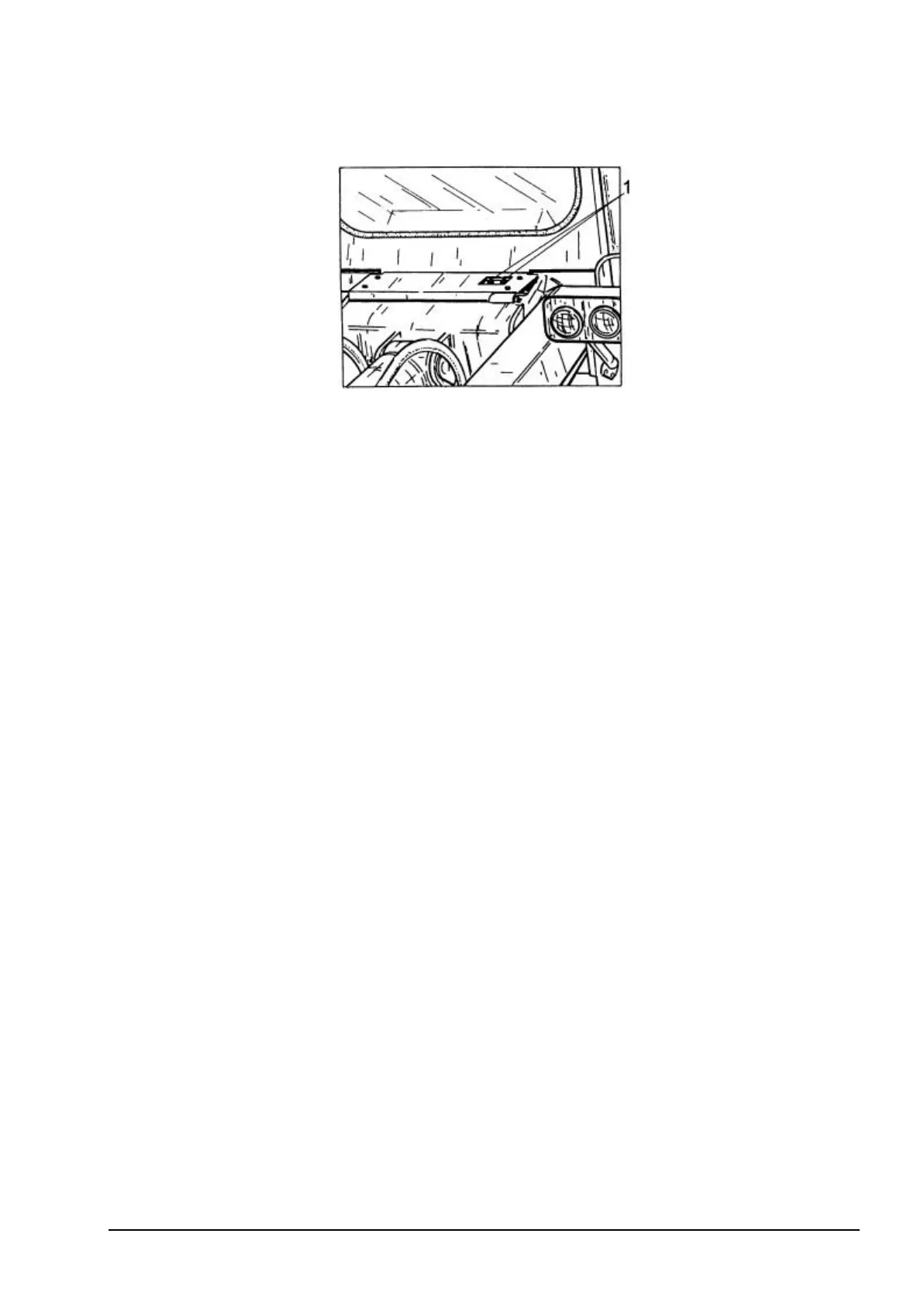

Fig. 5.13. Differential Valve.

1 - Vents

Two servicemen are required to perform the service. Vented are brakes of individual wheels,

differential valve signaling a failure of one brake system and the transmission disconnecting valve.

The differential valve is located on the front wall of the cab below the windscreen (access thru a

cutout in the platform), Fig. 5.13. The brakes and differential valve should be vented in accordance

with the procedure specified below (total of 6 vents).

1. After removing the protecting rubber cap install a transparent plastic tube on the vent valve. Put

the other end of the tube in a small amount of oil in a clean container.

2. Open the vent valve slightly by turning it, simultaneously the operator in the cab should depress

lightly the brake pedal (brake valve). Let the oil with air flow until the outflowing oil is free from air

bubbles.

3. Turn off the vent valve and release the brake pedal.

4. Install the protecting rubber cap.

5. Check that the valves are securely tightened with the brake valve fully open.

Pour the drained, clean oil into the transmission.

The venting procedure of the transmission disconnecting circuit is as follows:

1. Start the engine and let it operate at low idle with the transmission neutral lock lever and parking

brake applied.

2. Place the transmission disconnect switch in brake position with the transmission disconnected,

see INSTRUMENTS AND CONTROLS

3. Loosen hose fitting 2 of hose 1, Fig. 5.14. on the transmission at the transmission

disconnecting valve by app. 1 turn.

4. Depress slightly the brake pedal. Observe the outflow of air and oil at loosened hose

connection.

5. Tighten the connection when clear oil without air bubbles starts to flow.

Loading...

Loading...