SECTION 5 MAINTENANCE

Page 48

OM560C99/1E DRESSTA

TIRES AND RIMS

UNDERINFLATI0N

To little air pressure increases deflection, causes the tire to wipe and scuff over the road, results in

extra strain on the tire and increases the chance of bruising.

OVERINFLATION

Overinflation reduces the tire deflection and the tire contact area causing the tire to ride on the

crown and results in rapid wear in the center of the tread.

CHANGING

WARNING! Tire and rim repairs must be done by specially trained persons using

special safety tools. An improperly repaired tire or rim can separate suddenly

and cause serious injury.

Wheel rim components should be checked for damage and cracks. Damaged parts must be

replaced, NOT repaired. Disassembly of tubeless tire of this size is very difficult. Therefore, do not

replace parts yourself. Contact Construction Equipment Authorized Distributor or tire distributor

where persons with special training and safety tools are available.

5.18. TRANSMISSION AND TORQUE CONVERTER

5.18.1. CHECKING THE OIL LEVEL

WARNING! When it is necessary to make any checks or adjustments with the

engine running, use two people. A trained operator must be at the controls to

safeguard the mechanic making the checks or adjustments. Be sure the

transmission shift lever is locked in neutral (N), the frame halves are locked

together and the parking brake is applied.

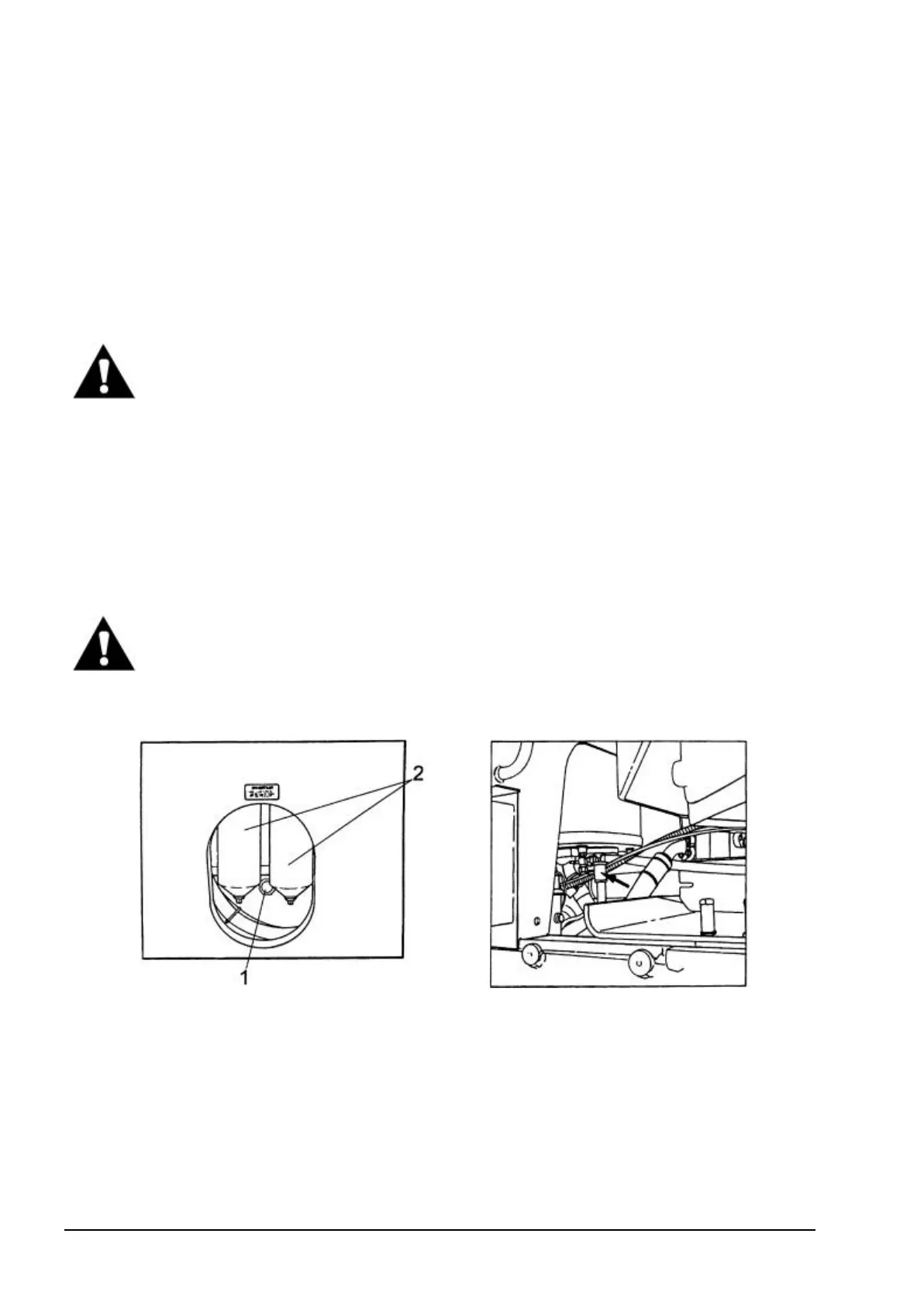

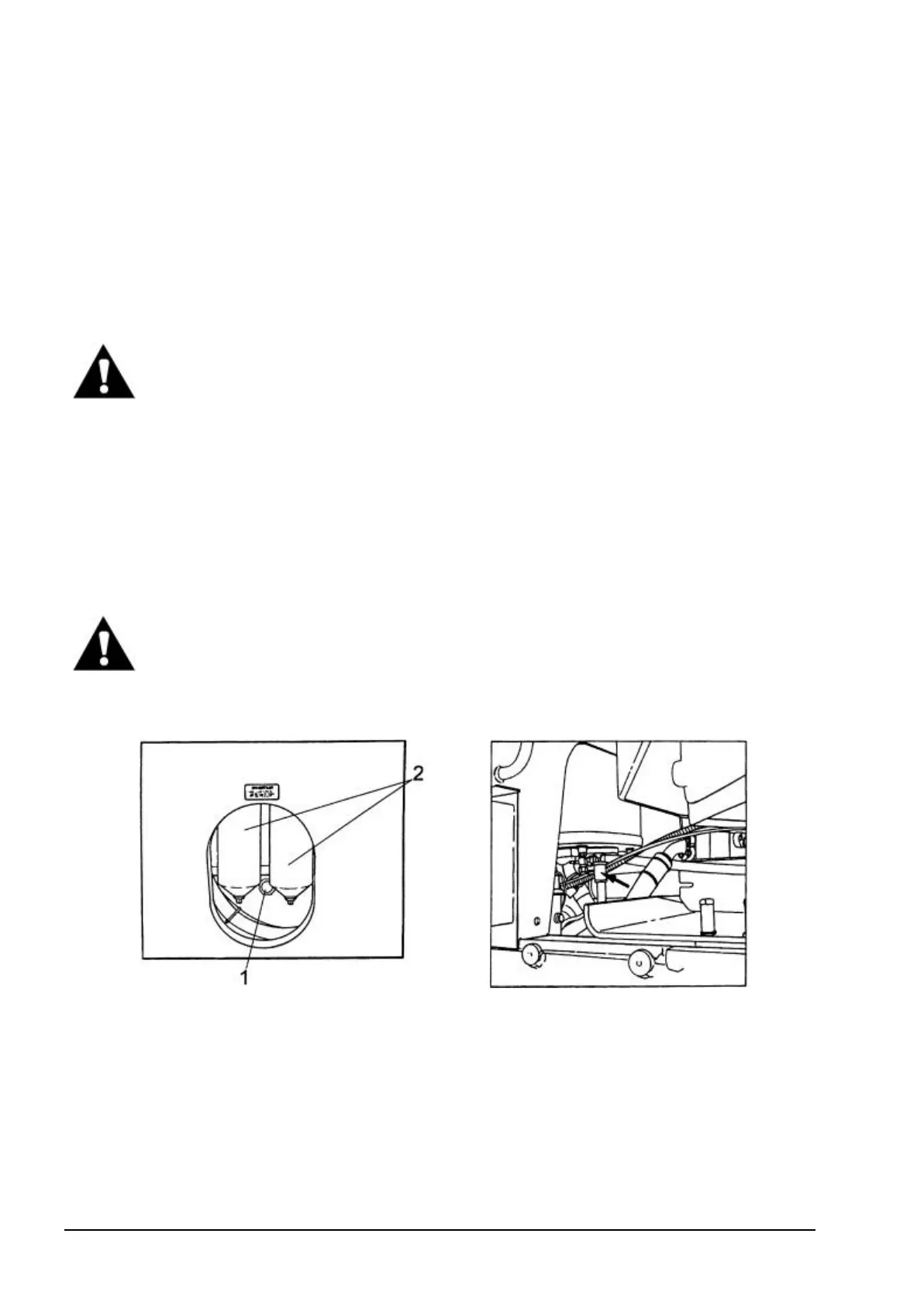

Fig. 5.53. Transmission Oil Level Sight Gauge Fig. 5.54. Transmission Oil Filler Tube

1 - Sight Gauge 2 - Filters

1. Park the machine on level ground.

2. Lock the transmission in "N" (neutral), lower the bucket to the ground and apply the parking

brake.

3. Stop the engine and install the frame locking bar.

4. Start the engine and let it run at low idle.

5. Check that oil can be seen in the top half of sight gauge 1, Fig. 5.53. in the cutout on the right

side of the rear frame close to the transmission. The transmission oil level is correct when the

ball is 10 mm above the middle of sight gauge with the engine running at low idle.

Loading...

Loading...