MAINTENANCE SECTION 5

Page 31

DRESSTA OM560C99/1E

DRIVE AXLES

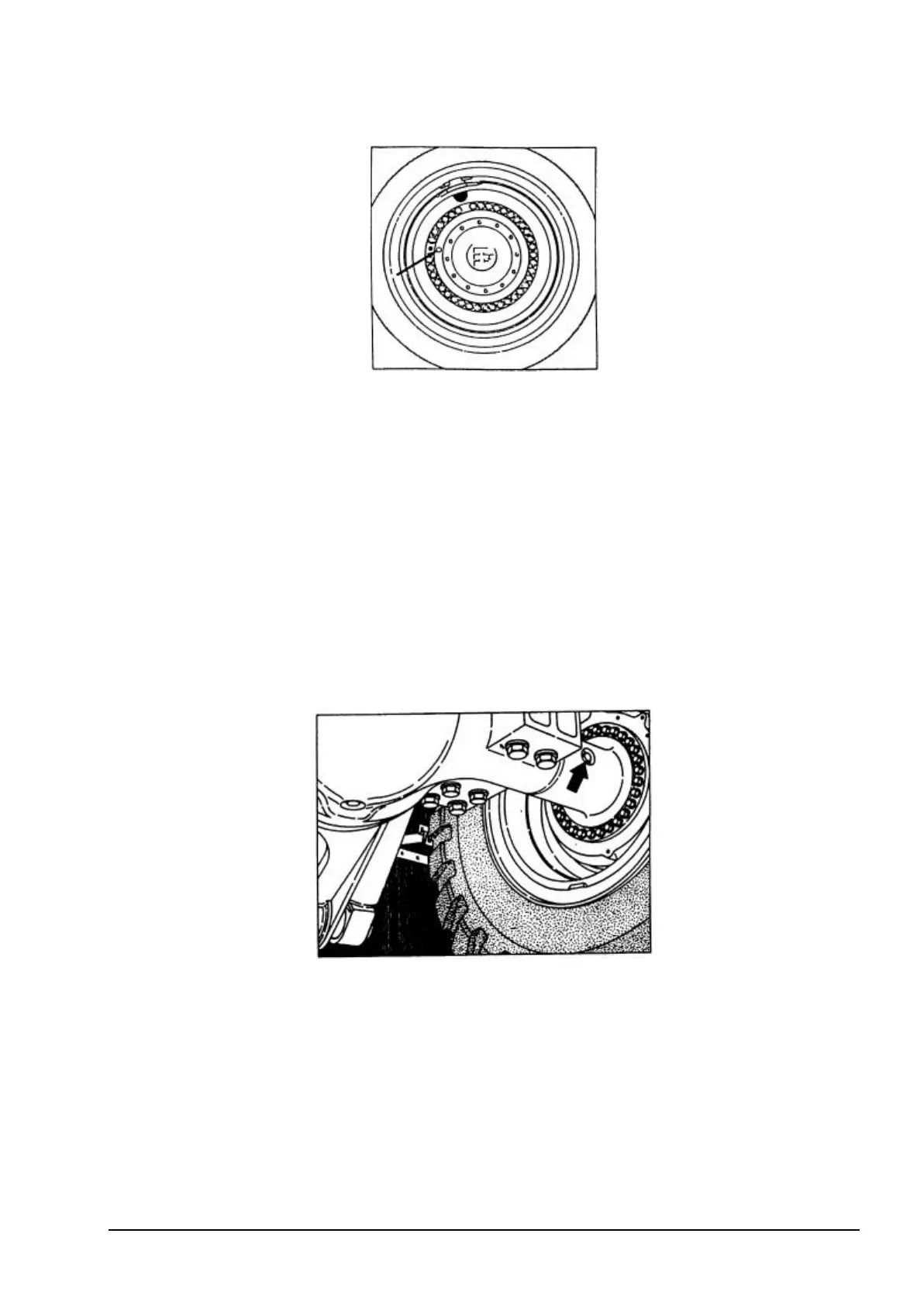

Fig. 5.26. Planetary Level Plug

3. Lubricant should flow from the planetary when the plug is removed. If necessary, remove the

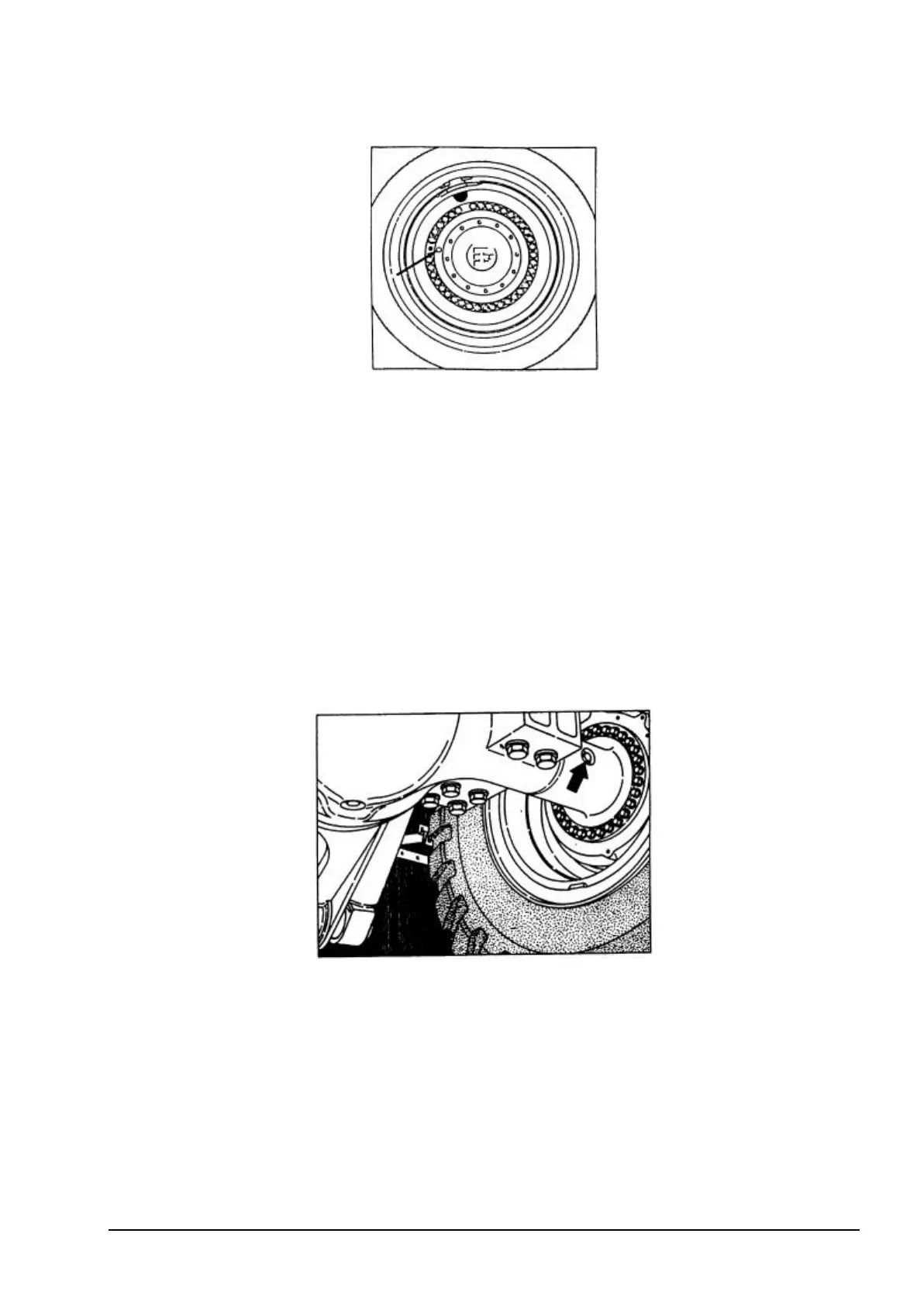

axle filler plug, Fig. 5.27 and add lubricant up to the level of the planetary level plug.

4. Install planetary level and axle filler plugs.

5.9.2. CHANGING THE OIL

1. Work the machine until the axle lubricant reaches the operating temperature. Park the machine

on level ground. Apply the parking brake. Remove the axle filler plugs shown in Fig. 5.27 and

drain plugs shown in Fig. 5.28. Allow lubricant to drain thoroughly.

2. Release the parking brake and move the machine only enough to locate each planetary plug in

turn to the lowest point for draining. With the drain plugs in this position remove planetary plugs

and drain oil. Allow lubricant to drain thoroughly. The above described steps should be

performed for all four wheels.

Fig. 5.27. Axle Filler Plug

3. Install the drain plugs in both axles. In the first axle install the planetary plug only in one wheel.

Moving the machine position the other plug in oil level check position (horizontal). Fill the axle

with fresh lubricant through the fill hole in the axle until the lubricant starts to flow from the hole.

Install all plugs. Fill the other axle in the same manner. Refer to REFILL SPECIFICATIONS

AND CAPACITIES CHART.

4. Operate the machine for a couple of minutes to distribute the lubricant throughout the axle and

planetaries.

5. Recheck each axle level as outlined above.

Loading...

Loading...