SECTION 5 MAINTENANCE

Page 38

OM560C99/1E DRESSTA

ENGINE

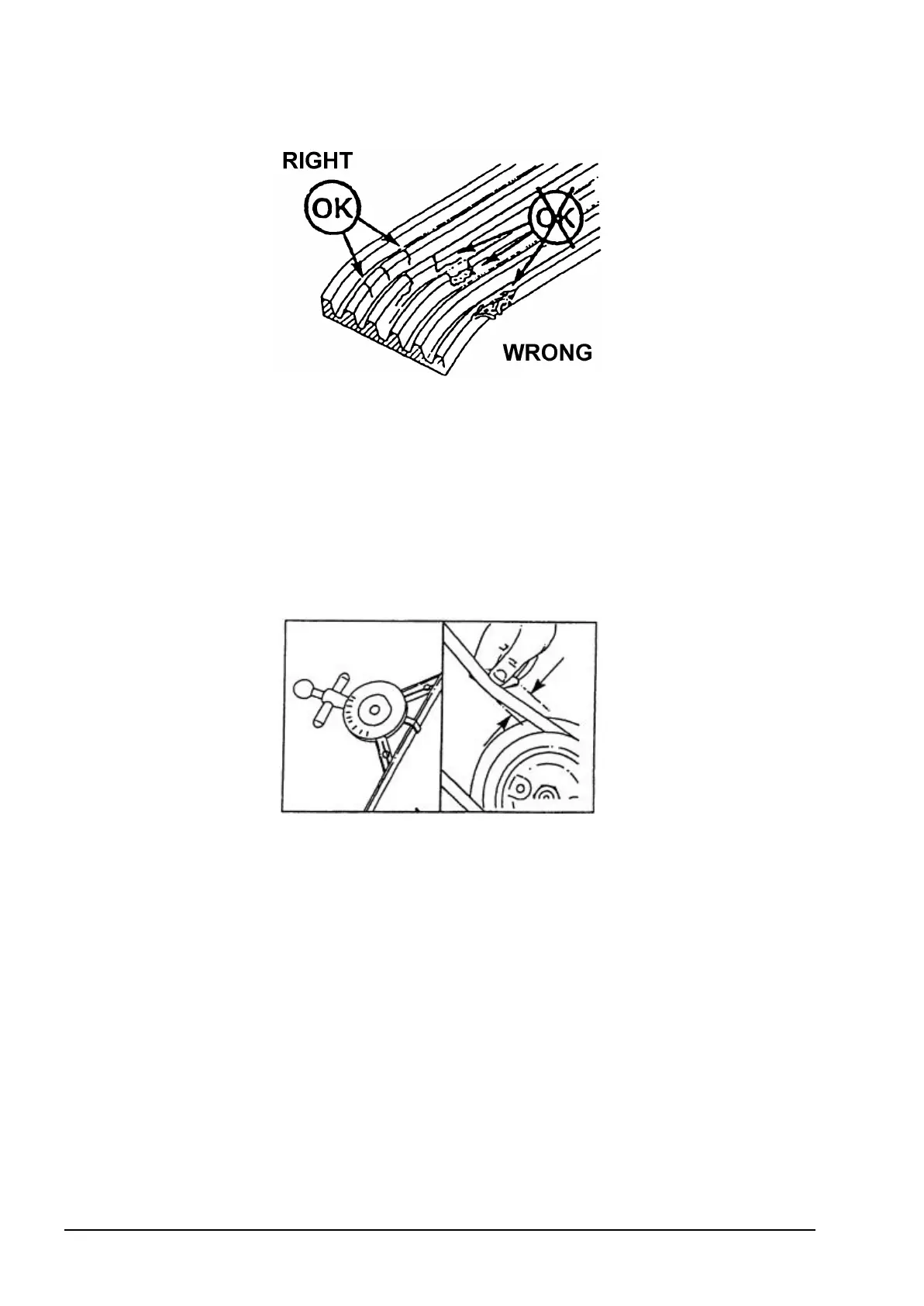

Fig. 5.36. Belt Inspection

Belt damage may occur due to:

− improper tension,

− improper installation,

− severe operating conditions,

− contamination with oil or grease.

CHECKING THE TENSION

Check the bet tension midway at the longest span between the pulleys using a tension gauge.

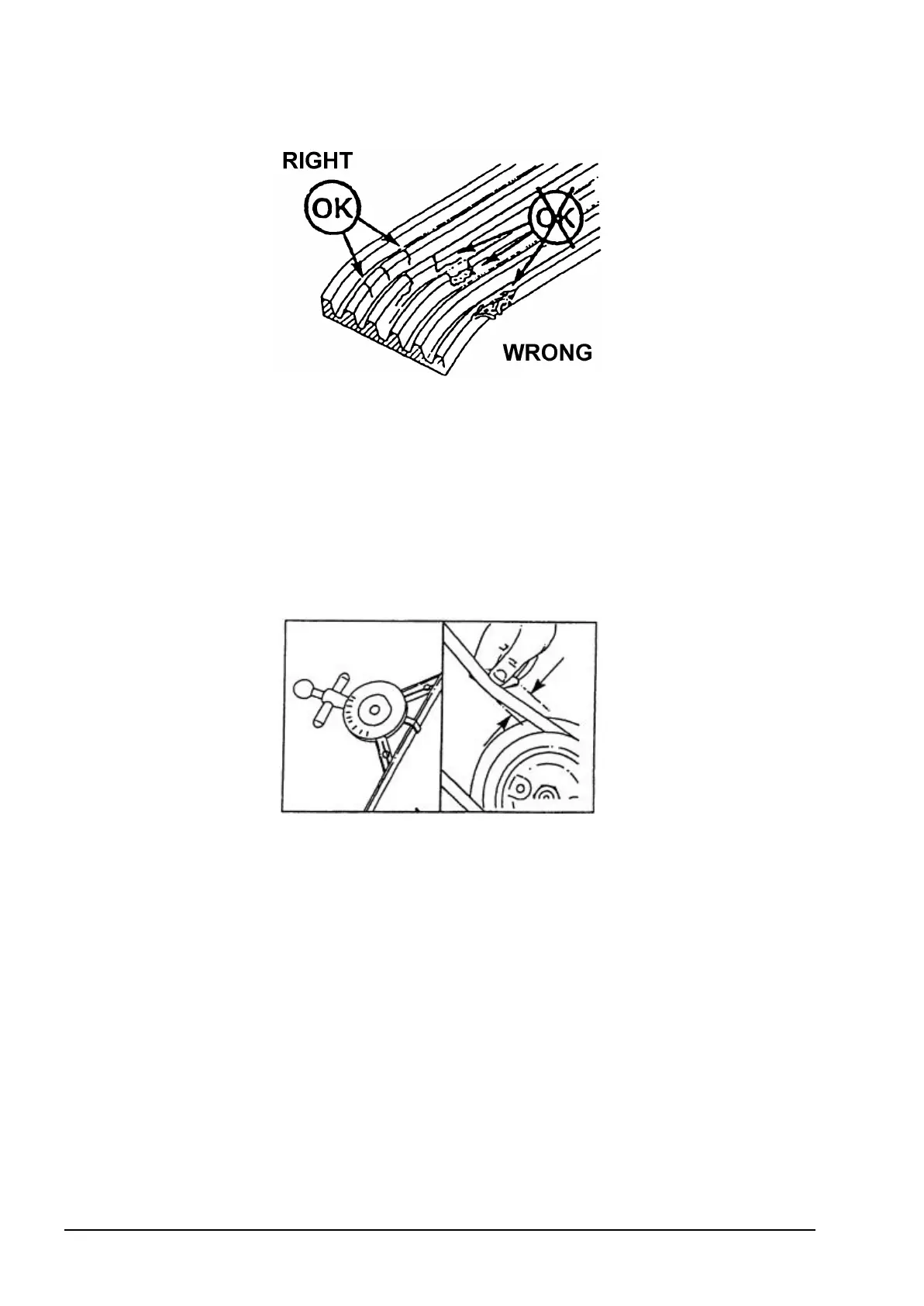

Fig. 5.37. Checking Belt Tension

Refer to Engine Operation Manual for the type of a tension gauge as well as the tension values for

various belt widths.

For QSK 19-C (5-groove belt) these values are as follows: a new belt tension 670 N, retension 270

to 530 N.

For KT 19-C (15-groove belt) those values are as follows: a new belt tension 1670 N, retension 670

to 1340 N.

A belt is considered used when operated at least 10 minutes.

Alternately belt tension may be checked by pressing the belt midway between pulleys as shown in

Fig. 5.37. Deflection under a force of 110 N should nor exceed belt thickness at a 30 cm distance

between the pulleys. Adjust the belt if deflection exceeds the above value. New belts loose their

tension during operation.

Loading...

Loading...