Operating Instructions For TD/TAD4 Dual Fuel Burner

June 13 128 of 165 TD/TAD4 Manual Rev 4

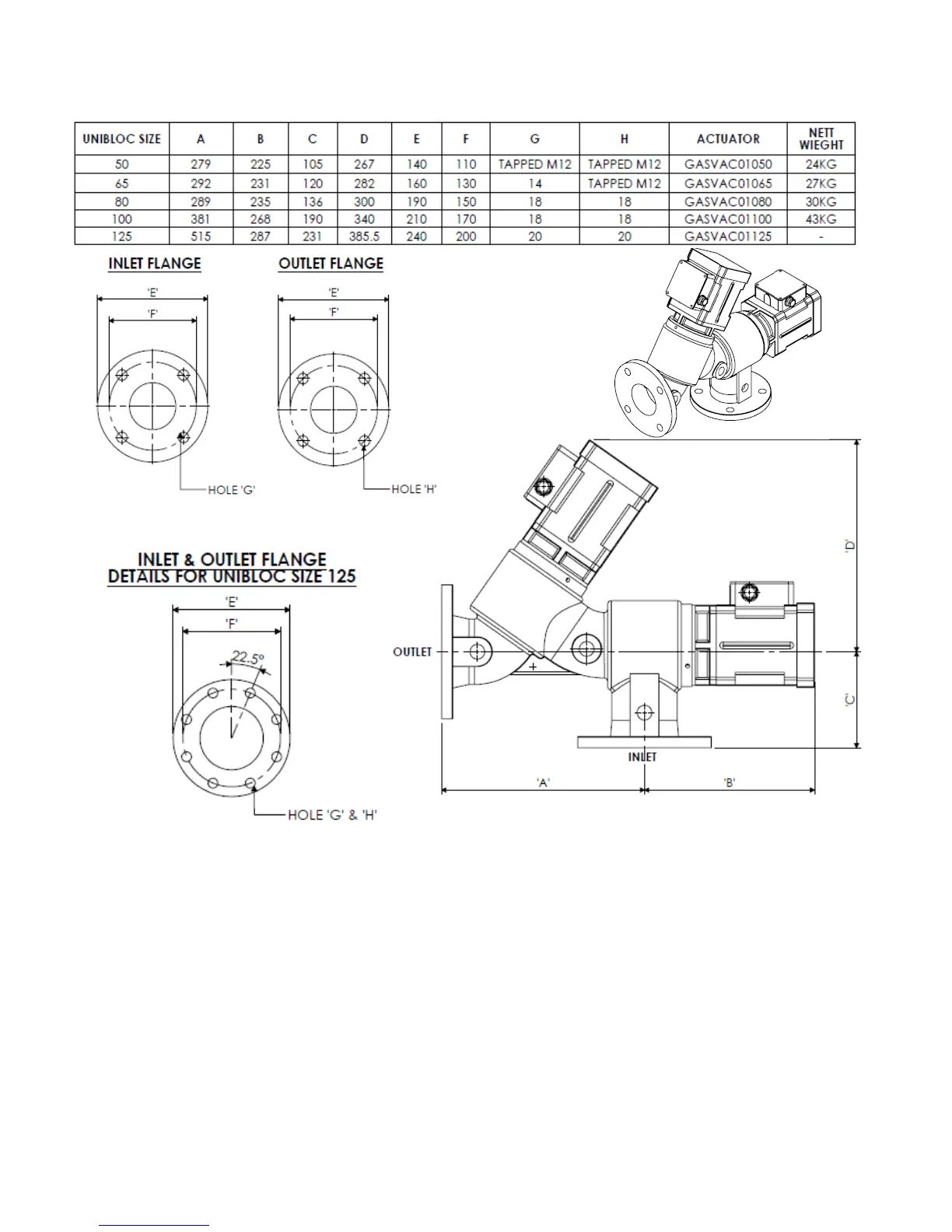

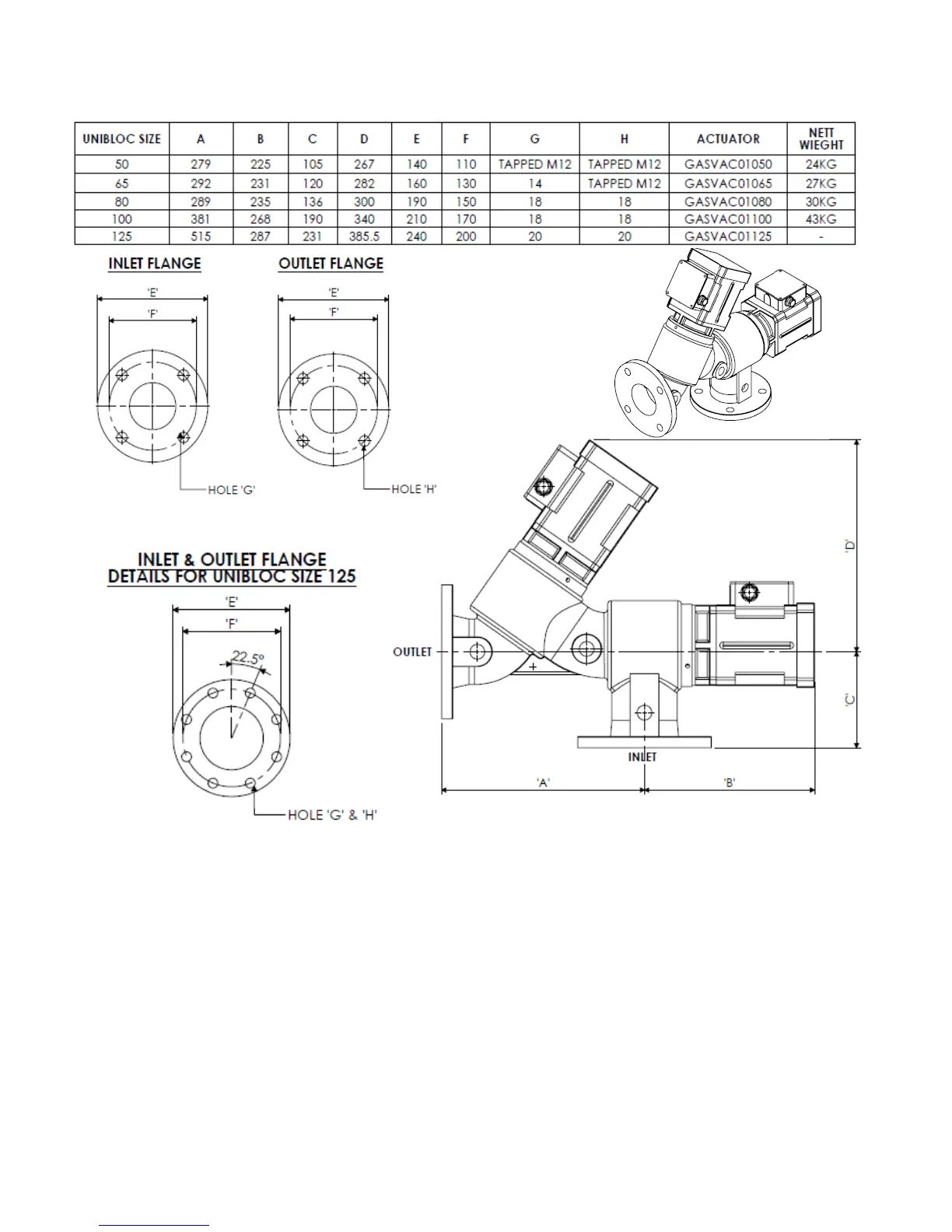

12.3 Unibloc

12.3.1 Unibloc General Arrangements

All Unibloc gas trains are manufactured and tested in accordance with EN 161 : 1991 'Automatic

Shut-off Valves for Gas Burners and Gas Appliances'

The Unibloc body is cast iron to BS 1452 grade 220 (the 100 N.B. body conforming to EN161 is

S.G. cast iron to BS 2789 grade 2712). All bodies are manufactured in one piece and are precision

machined to accept the various gas valve actuators that are described in section 2.

The standard unit is designed for use with 2nd and 3rd family gases and is fitted with plated carbon

steel valve seating rings. For other gas applications, e.g. bio or producer gas, the valve seating rings

are manufactured out of grade 321 stainless steel, because of the corrosive nature of these gases.

Where hydrogen sulphide (H2 S) is present in the gas advice must be sought from Dunphy

Technical Department.

A gas filter is fitted around the seating of the first stage valve to prevent foreign bodies entering the

Unibloc and causing valve seating problems. Gas filters are available to suit the various

specifications as required.

Loading...

Loading...