Operating Instructions For TD/TAD4 Dual Fuel Burner

June 13 40 of 165 TD/TAD4 Manual Rev 4

4.1.2 High / Low Oil

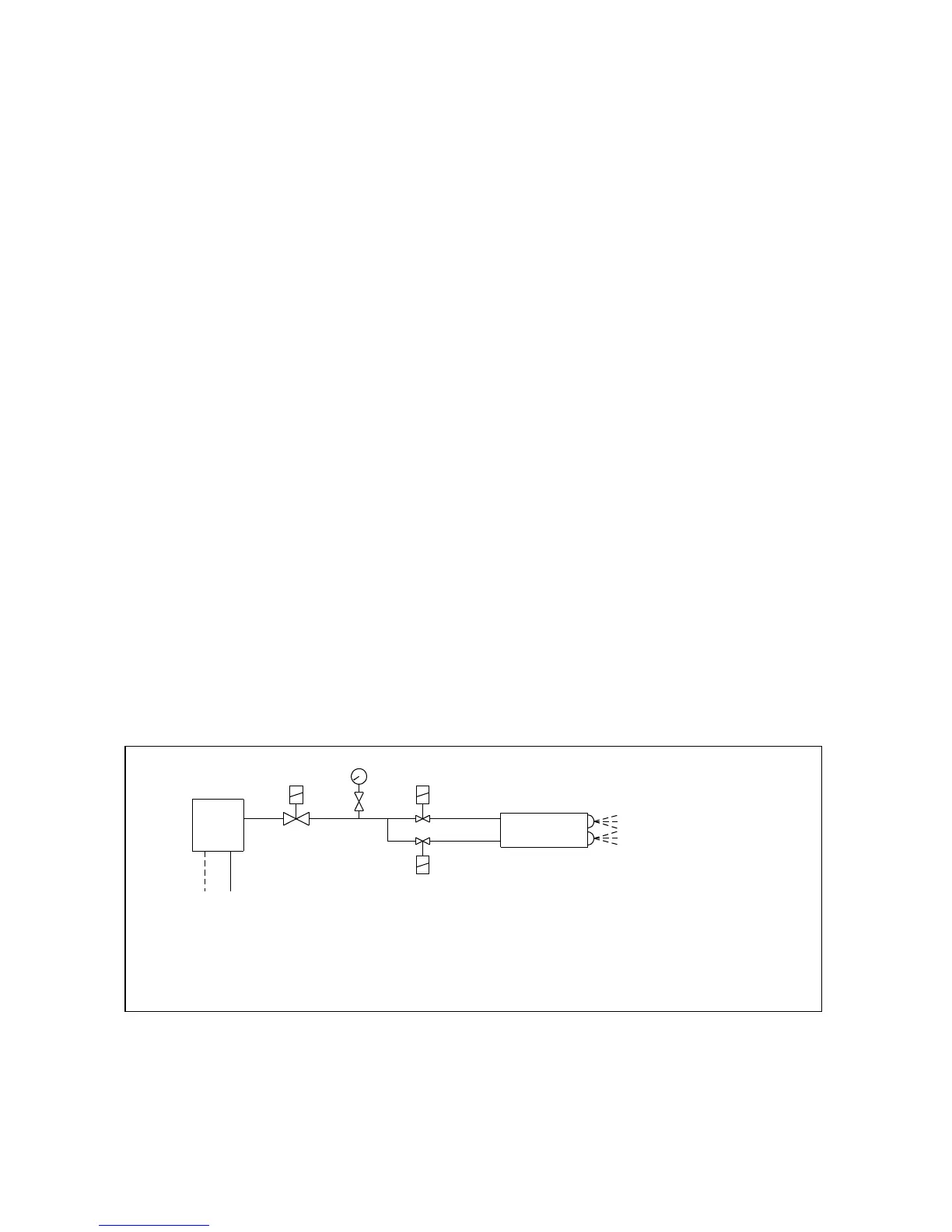

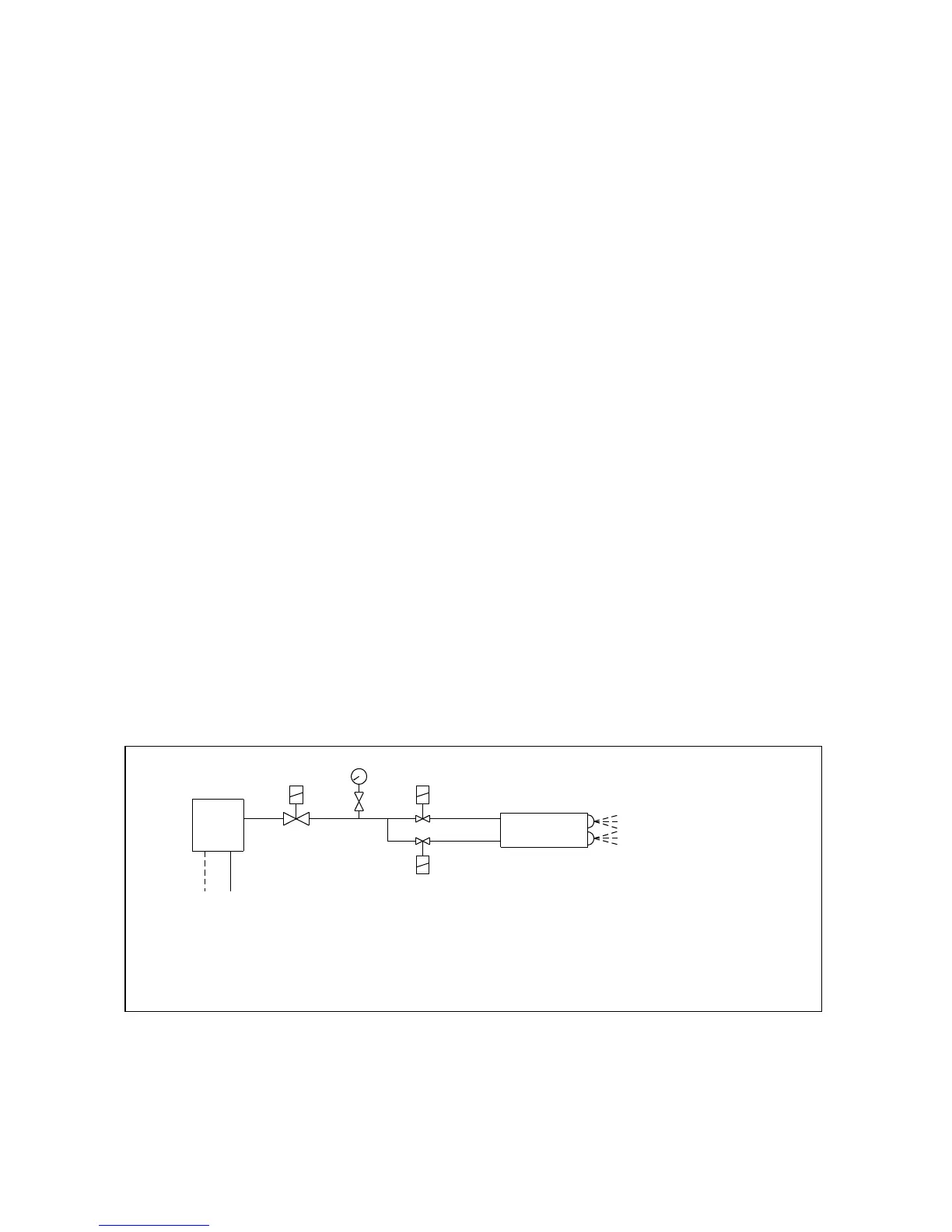

Atomisation of the fuel is by two separate nozzles, one for low fire and the second for high fire.

The oil supply to each nozzle passes through one of twin solenoid shut-off valves and the burner

output is determined by the size of nozzle and the pressure setting of the fuel pump regulator.

Normally, two nozzles of the same size will be used to give a total output equivalent to the

maximum continuous rating (MCR) of the appliance, and, At low fire, approximately 50% of

MCR.

Dissimilar nozzles can however be fitted to alter the low fire to high fire ratio. Nozzles of different

spray angle and patterns are used on various furnace configurations in order to give the appropriate

flame shape. The whole of the oil system is protected by a pump discharge valve ( PDV ) which is

fitted on the oil pressure outlet of the pump and which closes, isolating the oil system when the

burner is not running.

When the control box reaches the firing stage, the air damper drives to the low fire position

(CAM VI) and the ignition spark is switched on.

Both the PDV and first stage solenoid valve (V1) are energised simultaneously releasing oil

through the first stage nozzle, which is ignited by the spark from the ignition electrode.

The oil pressure should now be adjusted, by means of the pump pressure regulating screw, to give

approximately 50% of the MCR of the appliance and the air shutter adjusted to give optimum

combustion efficiency.

As the control box reaches the high fire stage, the air damper motor drives the air shutter to the

high fire position and sends a signal to the second stage oil valve (V2).

As a safety measure, the second stage oil valve is energised through an auxiliary switch in the air

damper motor (CAM VII). The logic of this arrangement is that the air damper must be in the `high

fire` position before the second stage solenoid can open, thus ensuring that an oil rich condition

cannot occur.

When a burner is switched from high to low fire, the closing speed of the solenoid will always be

faster than that of the air damper, so the combustion will again remain air-rich.

The oil pressure should now be adjusted, by means of the pump pressure regulating screw, to give

the full MCR of the appliance and the air shutter adjusted to give optimum combustion efficiency.

Nozzle throughputs are given in the table on the following page.

It is essential that, on completion, the burner is tried a number of times to ensure that changeover

between low and high fire is smooth and that the flame does not `lift off`.

Loading...

Loading...