Operating Instructions For TD/TAD4 Dual Fuel Burner

June 13 77 of 165 TD/TAD4 Manual Rev 4

8 Burner Maintenance Schedule

The following schedules are only to be taken as a guide to those persons responsible for day to day

maintenance of the burners. Details of a service agreement covering the major items of routine

servicing are available on request.

An annual check by factory trained technicians is strongly advised.

All control circuit components, fire valves and other safety devices should have a functional check

at not greater than annual intervals.

Maintenance and inspection of boilers or other appliances must meet the requirements of the

manufacturers' schedules and of the insurers. It is usually more convenient to carry out burner

maintenance after the completion of the boiler inspection or cleaning, so that the burner can be fired

and the combustion reset to optimum figures.

The measurements given in the various combustion head drawings in this manual are to be regarded

as datum figures only. During commissioning, alterations may be made to the relative positions, or

to the components themselves, to suit the particular application.

Therefore, before dismantling the combustion head, take note of the measurements concerned and

record them on the manual's drawings. It is important that where possible components of the same

type and size are fitted as replacements.

The commissioning certificate for the burner should be available, to be used as a reference for the

fuel input and combustion figures which will give boiler MCR and the highest efficiency level.

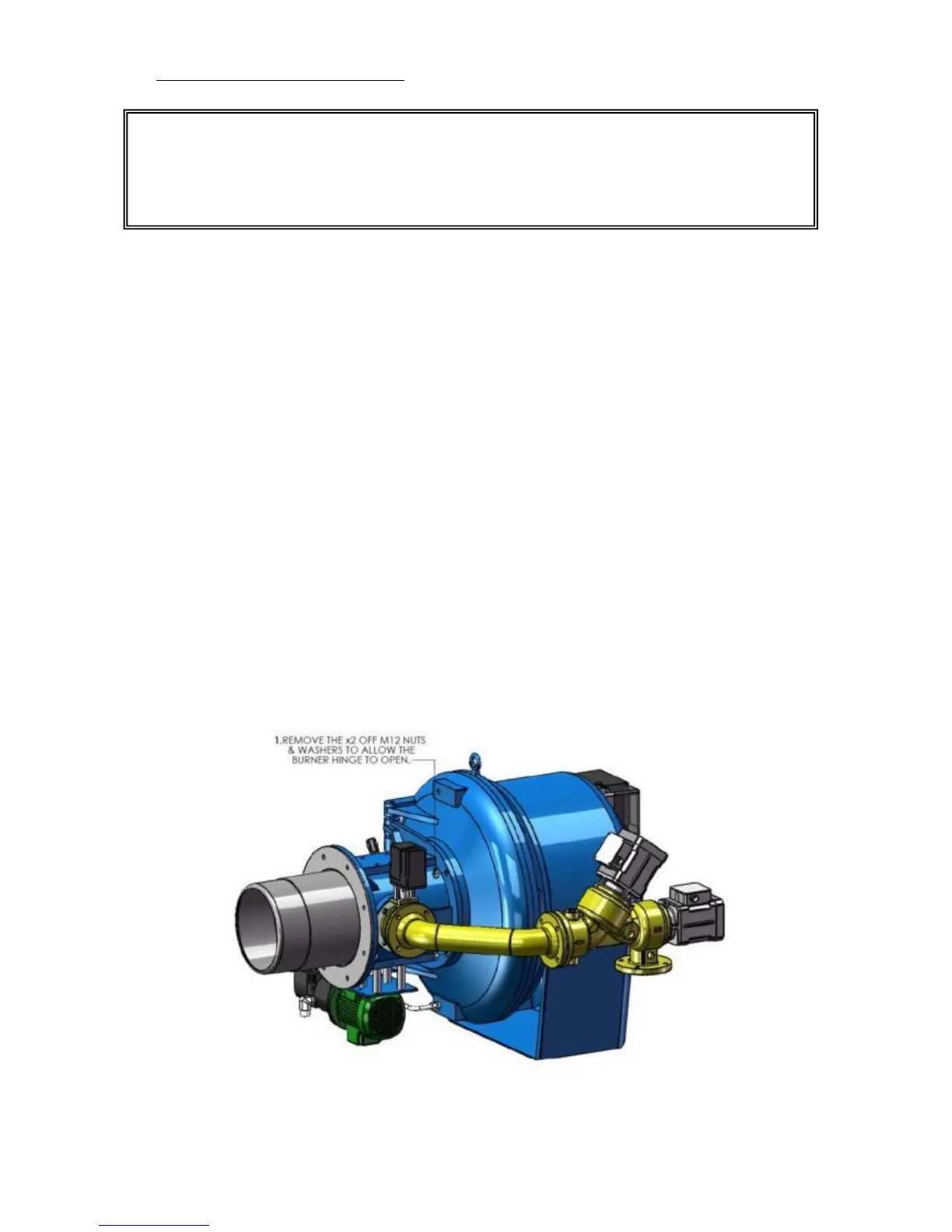

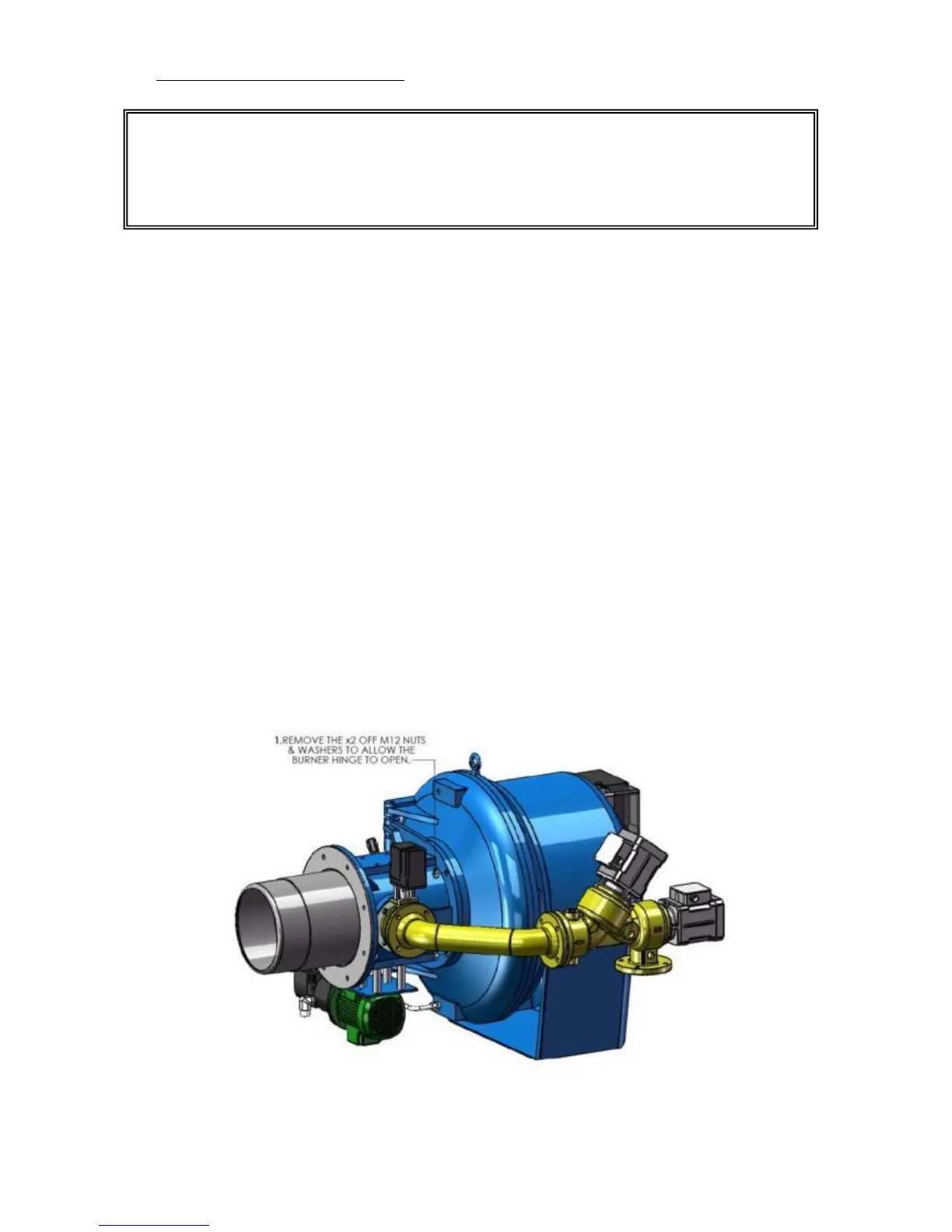

8.1 Opening the Burner

To open the burner, the two nuts securing the hinge section to the fan section must be removed. The

burner will swing open on its hinge offering full access to all combustion head components.

When necessary checks/repairs have been carried out, close up in reverse order ensuring that the

locking nuts are fully tightened.

Loading...

Loading...