Operating Instructions For TD/TAD4 Dual Fuel Burner

June 13 22 of 165 TD/TAD4 Manual Rev 4

With the gas isolation valve next to the burner closed, a pressure test should be carried out on the

main gas supply pipe work and all connections checked with a suitable, non corrosive leak

detection fluid.

If the installation is supplied with a gas pressure above 1 bar (14.5p.s.i.g.) and contains plant with a

heat input of more than 2MW, local authorities will generally ask for the fitting of remotely

operable fire valves. The national or other standards in countries to which the burners may be

exported must be identified and met.

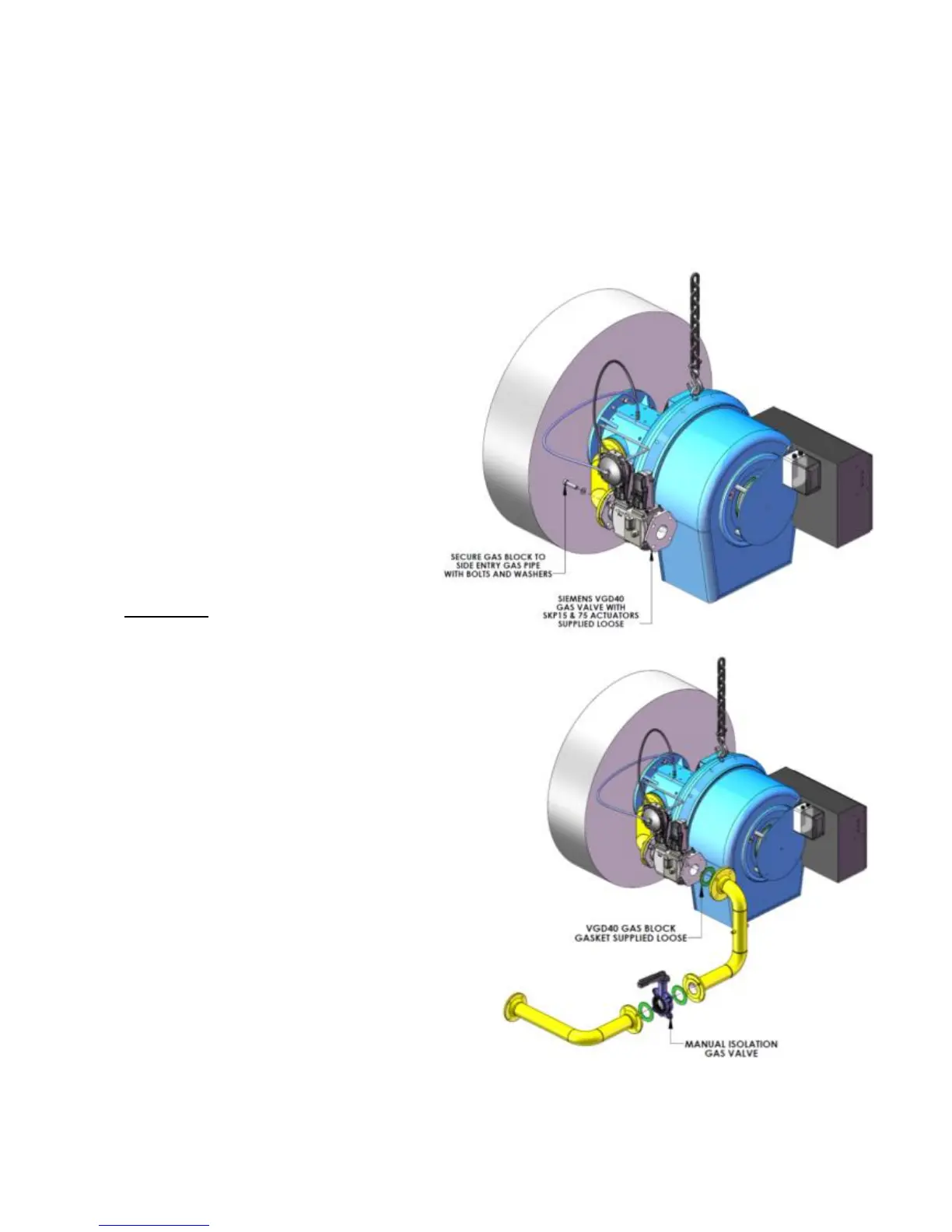

2.2.2 Burner fitted with Siemens VGD40 gas valve

The Siemens gas valve is a heavy item

and will require two persons to lift it into

position and secure in place using bolts

provided.

8mm blue and black PVC pipes plus

fitting are supplied with the burner. The

blue line must be connected between the

“Air” connection on the SKP75 actuator

and the air pulse line situated on the top

flat of the burner hinge section. The black

line must be connected between the

“Combustion Chamber” connection on the

SKP75 and the furnace line connection

protruding through the mounting flange of

the burner.

Important:

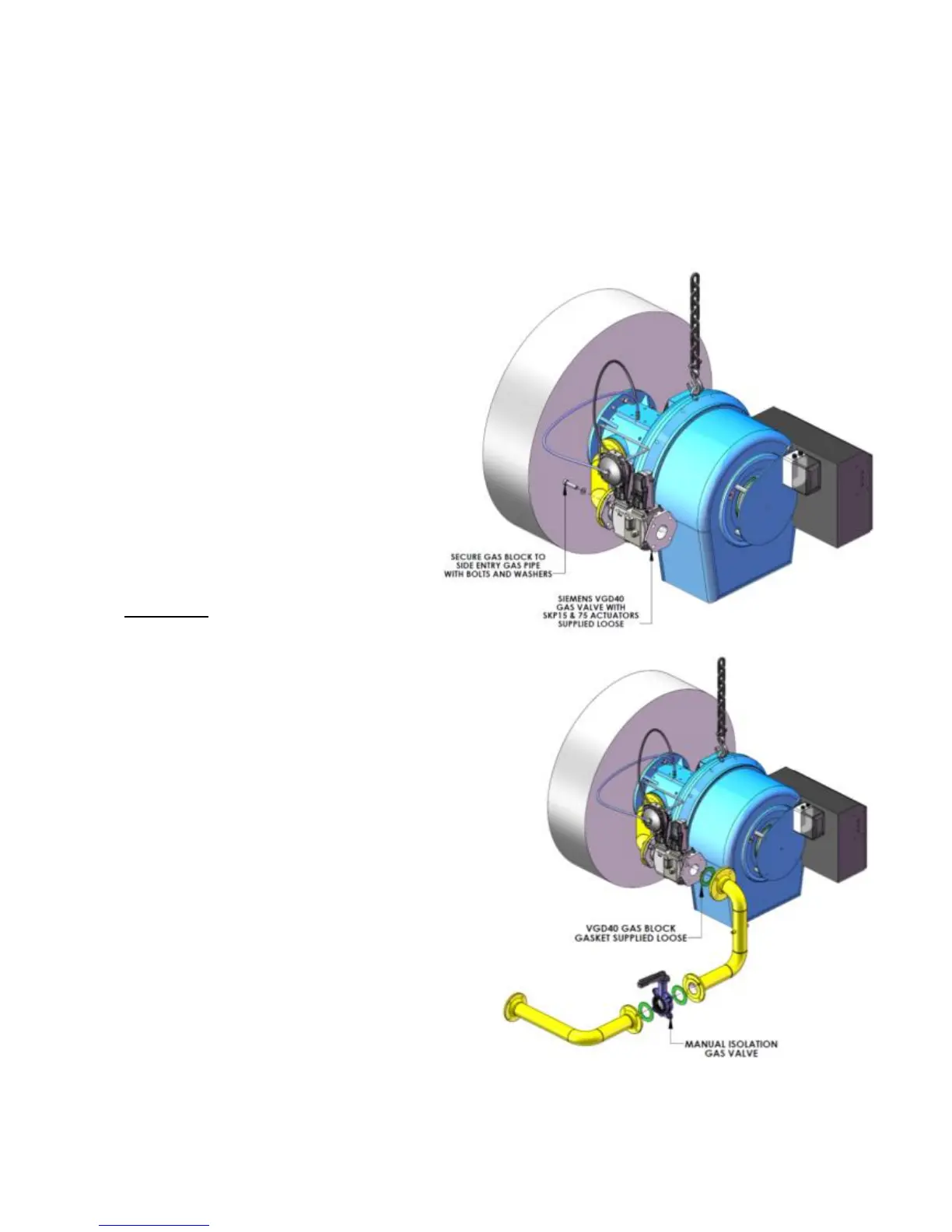

The installer must install a 90° turn type

isolation ball valve next to or in close proximity

to the burner and capable of rapid operation.

The manual valve must be capable of operating at

a pressure equal to 1.5 times the maximum supply

pressure and where possible must be orientated in

such a way that when the valve closes the handle

must fall from the vertical to the horizontal. The

valve must have mechanical end stops to prevent

the ball valve from going below the 0° point or

above the 90° point.

The gas supply pipework must be adequately

supported to prevent undue stress on the burner

casing or the gas train components.

The Siemens gas valve has a built-in governor and

is suitable for gas pressures up to 500mBar.

Gas supplies greater than 500mbar must be

governed down to a suitable gas pressure below

500mbar using a CE approved high pressure gas governor. The gas governor or should be fitted as

per manufactures instructions, copies available on request.

Loading...

Loading...