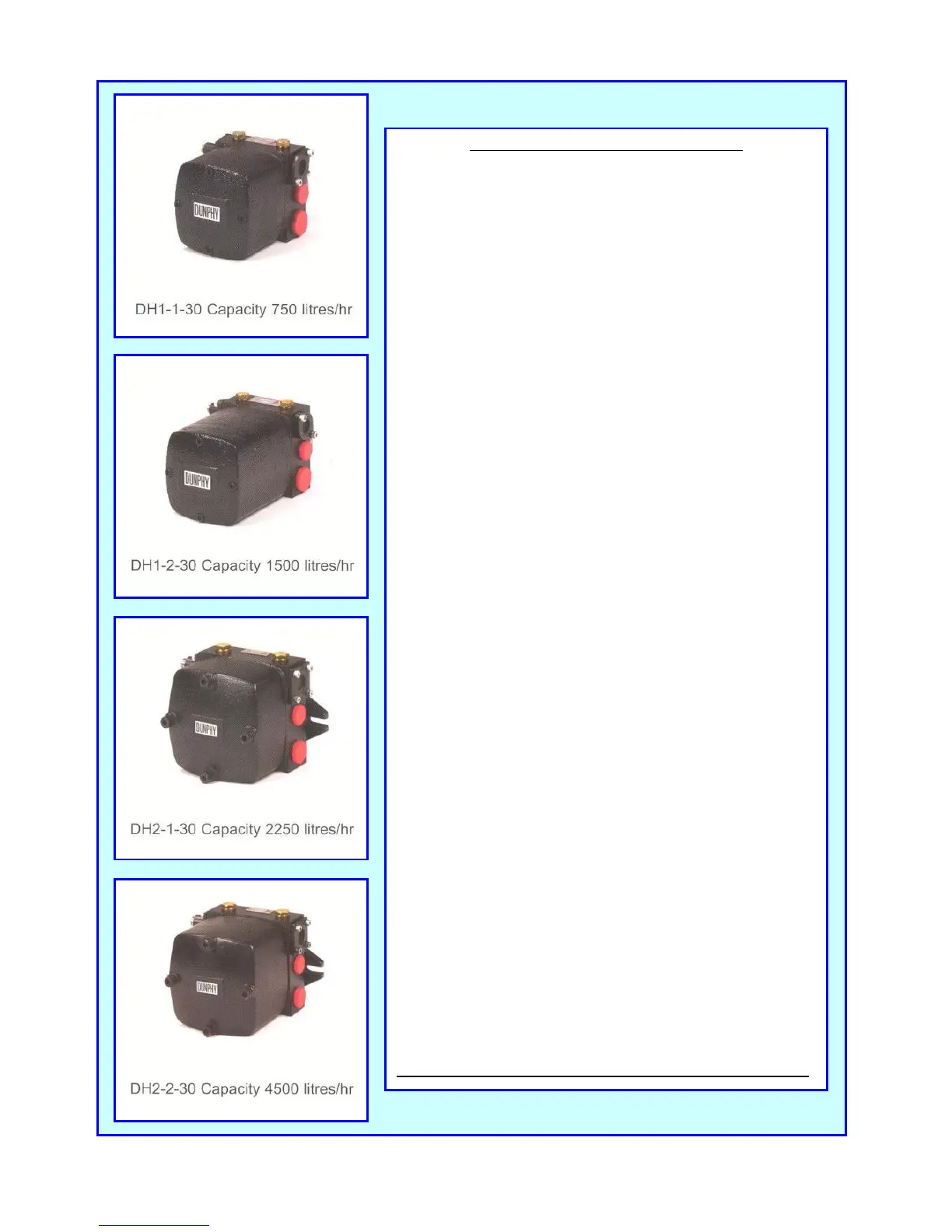

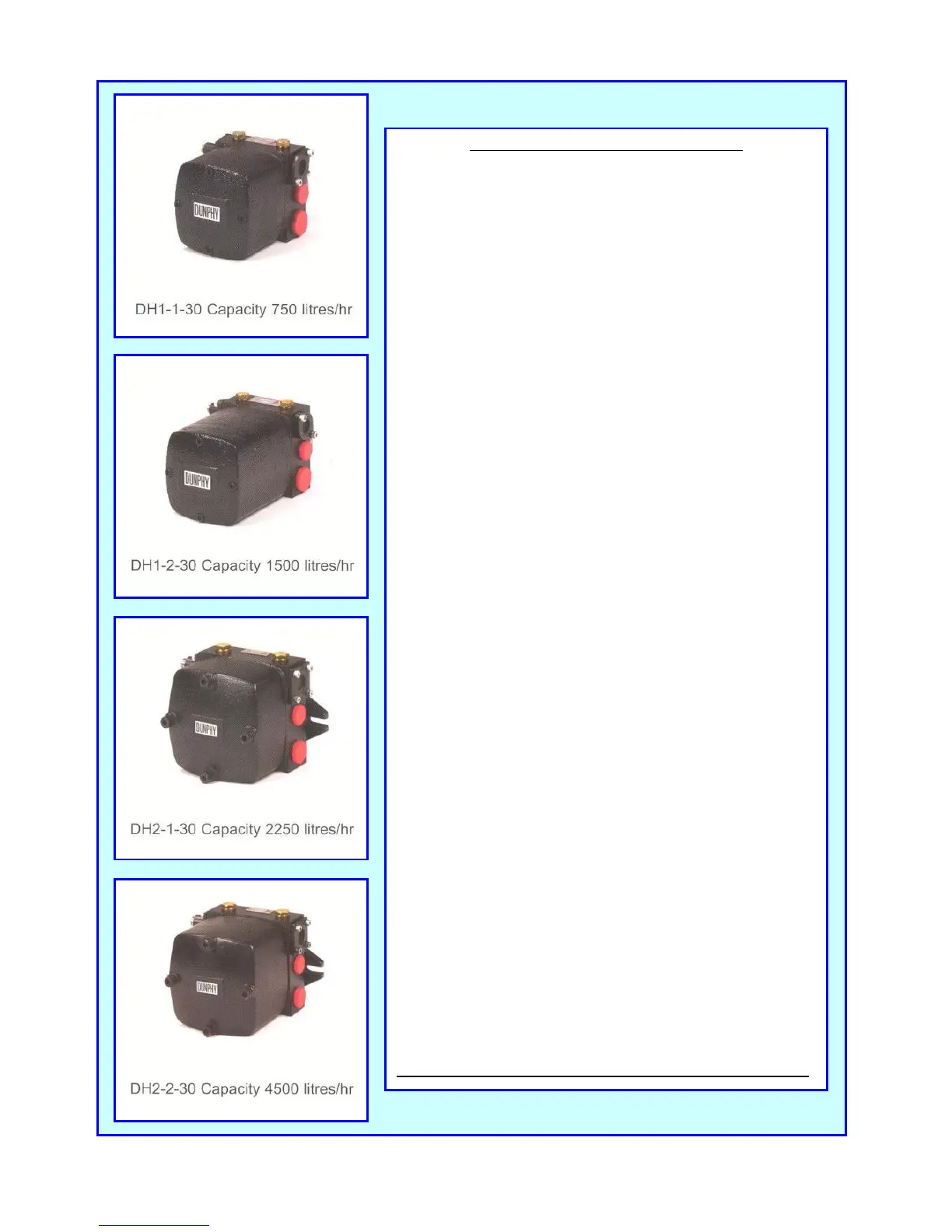

`DH` SERIES GENERAL DESCRIPTION

The oil pump is a vital part of any oil fired heating plant, whether

being used as a transfer pump for pumping oil at low pressures or on

an oil burner delivering oil at 35 bar.

The Dunphy DH series pump has been specifically designed to

overcome the problems associated with current grades of fuel oils in a

variety of different situations, giving accurate pressure control

combined with reliability and performance.

The pump housing is Grade 14 cast iron that is precision machined to

accept the various combinations of gear sets that are available to suit a

wide variety of applications.

Exhaustive work on test rig and field trials that internal leakage’s in a

gear pump are most severe through the lateral running clearances.

They are less severe through the radial clearances, here, the leakage

path is long and the rotation of the gears opposes the pressure gradient.

Based on these observations a `Sandwich` construction of the gear-set

and the pumping chamber has been designed from first principles.

Calculations and computer modelling gave clear figures for the very

high bearing loads resulting from high liquid pressure acting on the

projected area of the gears. As a result, the design has catered for

bearings of large surface area. This must result in minimal rubbing

speed. They must also provide rigid shaft support with no appreciable

deflection.

The final design provides all DH series with gear-sets of nitrogen

hardened steel supported by an extremely strong bearing assembly.

It enables the standard unit to handle fuels with viscosities from 2 up to

2000 centistokes at pressures up to 35 bar and temperatures of up to

140ºC.

Single or tandem gear-sets can be offered as standard. Pumps with

special series gear-sets can be offered for specific applications.

The most characteristic and frequent failure of oil pumps is that of

pump seizure. In operation, a gear pump is required to deliver the

maximum possible volume for a given centre distance and face-width

of the gears. Losses due to internal leakage must be minimal and

sufficient only to provide adequate lubrication of the rotating parts.

However, the capacity of the gear-set depends on the depth of the gear

tooth. Design must therefore cater for a minimum number of teeth and

for minimum peripheral rubbing speeds

These parameters were used in making a choice between an internal

pinion and rotor format and an external gear-set employing straight

spur gear teeth of corrected involute form.

Dunphy engineers chose the external gear-set because it provides

maximum capacity for minimum peripheral rubbing speeds.

This factor is of vital importance in the elimination of pump seizure.

Loading...

Loading...