Operating Instructions For TD/TAD4 Dual Fuel Burner

June 13 154 of 165 TD/TAD4 Manual Rev 4

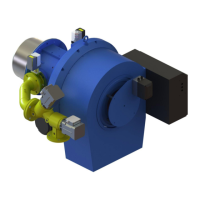

12.7 Variotronic VT Oil Metering Valve

12.7.1 General Description

The Variotronic oil valve has been designed to work primarily in conjunction with electronic

positioning motors for the accurate control of fluids, fuel oils and liquids as defined in the

specification of recommended applications.

The design of the valve incorporates an adjustable linear characterising spool which enables the

valve to operate to a virtually linear characteristic. the characterising spool adjusts the output of the

valve in relation to the metering valve spindle. This changes the flow rate of the valve - thus

ensuring that the maximum angular rotation is utilised to optimise the flow accurately.

12.7.2 Construction

The valve construction consists of a carbon steel body which is

drilled at each end to accommodate the valve output port and the

valve retaining cap. The output port is secured by 6 screws with an

oil seal 'O' ring sealing the face of the end cap and valve body. An

identical construction is on the drive end of the valve.

The end cap has a duel function in retaining the spool sleeve and

providing a clamp for adjustment. The valve control flow spindle is

mounted directly through the spool and retained by the output port

plate. This also has a duel function acting as a surface thrust plate

for the valve control. When the valve is used in conjunction with an

electronic servo motor, there are mounting pillar locations provided

at 52mm hole centres (which is the European standard for the 4Nm

required torque for operating this type of valve.)

12.7.3 Valve Maintenance

All rotating valves do eventually require maintenance, but maintenance is only generally necessary

as a result of wear on oil seals or 'O' rings. as a general guide we recommend that 'O' rings are

normally re-placed every 2 years or 20,000 hours, but this could vary on the type of fuel being

used, generally when operating on heavy fuel oils the service frequency should be reduced to 12

months. The normal grade of 'O' ring seals fitted within the valve is Viton.

Special materials are available for corrosive or fuels that contain corrosive substances. The

general service and maintenance of the valve is a very simple operation and all the seals could be

changed within a matter of minutes. It is essential to ensure that all replacement seals are of the

correct specification, any deviation from the specification could lead to premature seal failure and

even leakage from either the valve spindle or retaining faces.

12.7.4 Changing Seals

It is recommended that a spare set of seals is always retained for service and maintenance of the

valve. Changing the seals is a relatively simple task.

A. Isolate all electrical and fuel supplies

B. Ensure that the valve is cold and that there is zero pressure within the hydraulic circuit

C. Disconnect the valve drain mechanism, either mechanically or via electric servomotor

D. Before dismantling the valve, ensure that the positions are appropriately marked so that the

re-assembly, particularly of the spool ring can be repeated to the original settings. Remove

the 2 pillars securing the index plate. this will then expose the 4 countersunk retaining

screws on the valve retaining cap. The valve can then be de-assembled.

Loading...

Loading...