30

6. OPERATING PROCEDURES

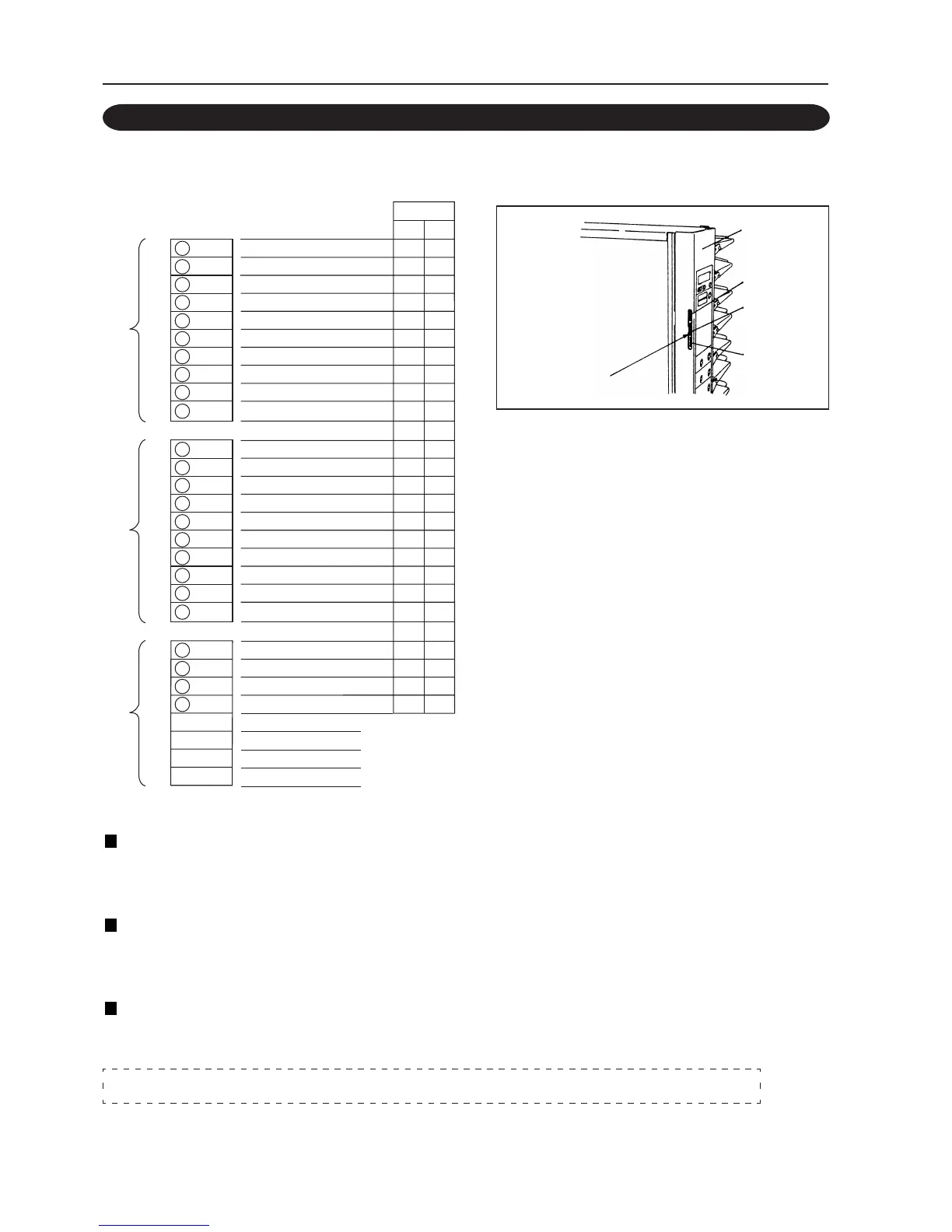

6-5. DIP SWITCHES

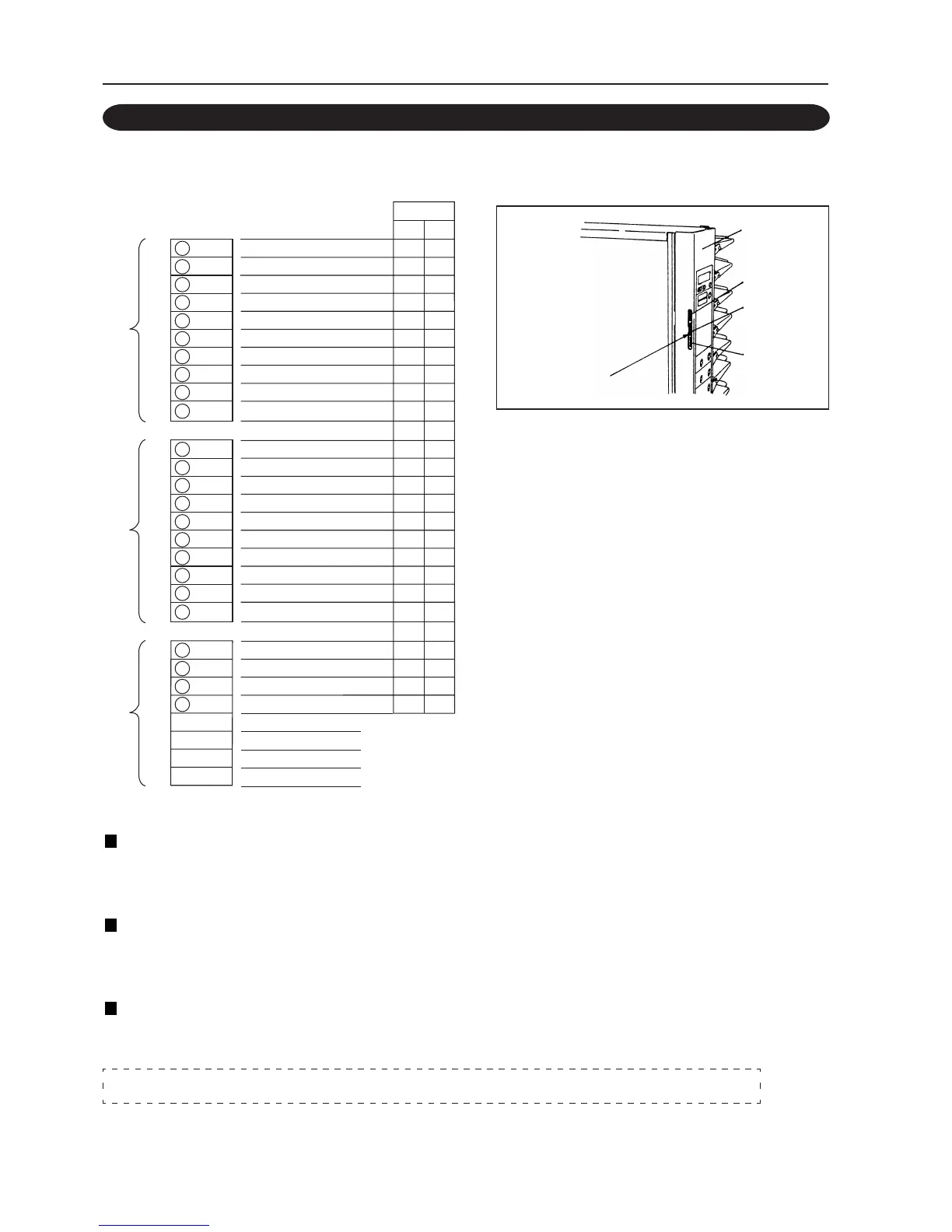

• The dip switches are located inside the cover.

• The functions of the dip switches and settings at factory are as shown in the figure below.

Dip Switch A

• When a paper jam sensor of a paper feed table breaks down, as a temporary measure, this dip switch can be turned

on to stop the sensor.

Dip Switch B

• When the multi-feed sensor breaks down, or cannot be used because special paper is used, this dip switch can be

used to stop the function of the multi-feed sensor.

Dip Switch C

• When the paper full sensor, paper ejection unit (UNIT) jam sensor, or bridge paper jam sensor breaks down, this

dip switch can be used to stop the function.

Dip switches are used mainly as temporary measures. To use them, consult your service engineer.

® mark : means the setting position

1

2

3

4

5

6

7

8

9

0

A

1

2

3

4

5

6

7

8

9

0

B

1

2

3

4

5

6

7

8

C

Dip Switches

OFF ON

Yes No

Effective

Not

effective

Overlap small

Overlap big

Paper full detection

UNIT- bridge detection

Don’t use

Don’t use

Don’t use

Don’t use

Detects multi-feeding at 1st table

Detects multi-feeding at 2nd table

Detects multi-feeding at 3rd table

Detects multi-feeding at 4th table

Setting

OFF ON

Detects paper jamming at 1st table

Detects paper jamming at 2nd table

Detects paper jamming at 3rd table

Detects paper jamming at 4th table

Detects paper jamming at 5th table

Detects paper jamming at 6th table

Detects paper jamming at 7th table

Detects paper jamming at 8th table

Detects paper jamming at 9th table

Detects paper jamming at 10th table

Detects multi-feeding at 5th table

Detects multi-feeding at 6th table

Detects multi-feeding at 7th table

Detects multi-feeding at 8th table

Detects multi-feeding at 9th table

Detects multi-feeding at 10th table

Effective

Not

effective

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Dip Switches

Cover

A

B

C

Loading...

Loading...