Replace any worn components.

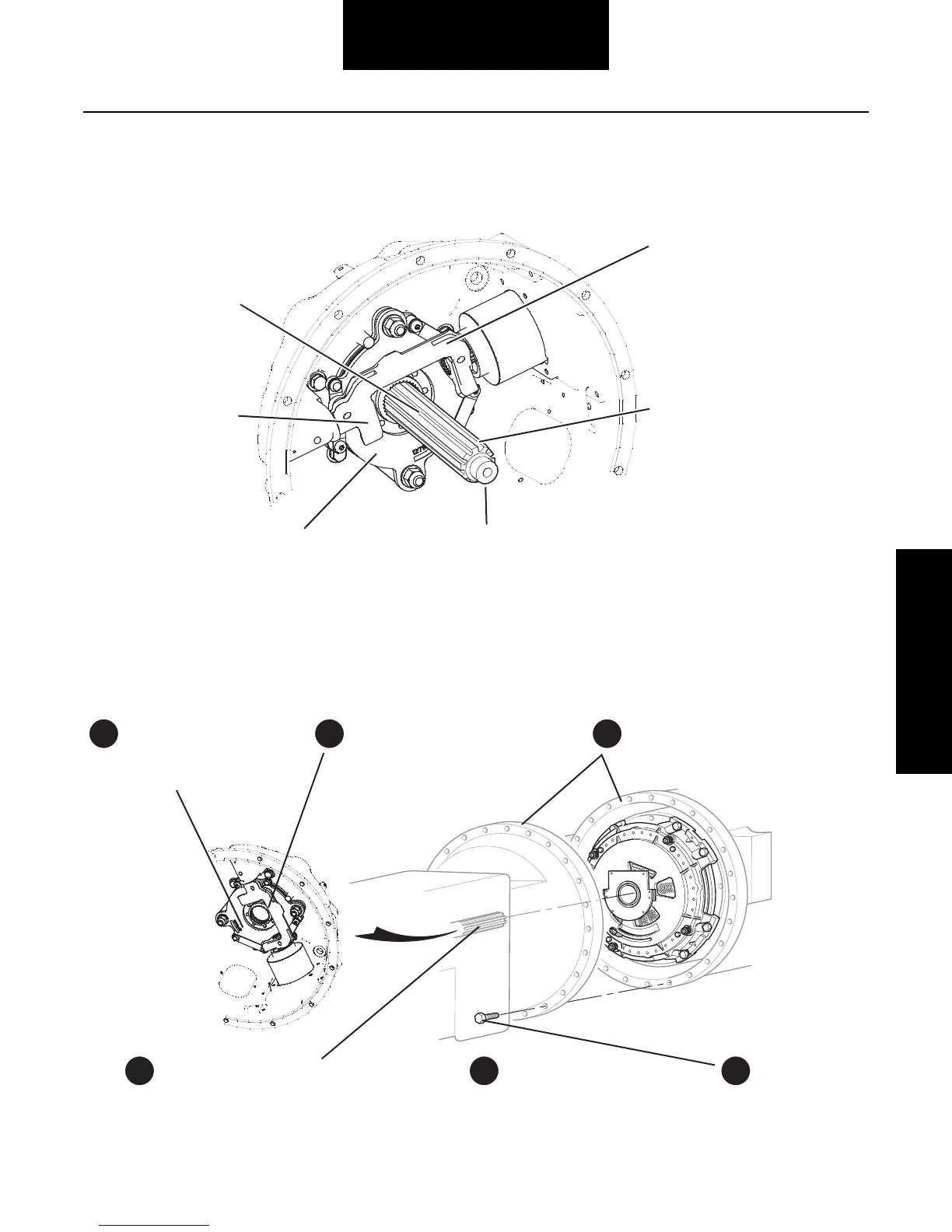

Input Shaft

Wear (roughness) can reduce

sleeve bushing life and cause

it to become dislodged.

Low Capacity Inertia Brake (LCIB)

Eaton requires that you replace the LCIB

when replacing the clutch. See Appendix A

for LCIB removal and installation instructions.

Cross Shaft And Bushings

Excessive wear at these points

can cause side loading on the

sleeve bushing, bushing

failures and yoke bridge

contact with the clutch in the

release/open position.

Input Shaft Splines

Any wear on the splines will

prevent the driven discs fr

om

sliding freely, causing poor clutch

release (clutch drag). Slide discs

full length of shaft to check for

twisted shaft splines.

Release Yoke

Worn rollers can cause

bushing wear and yoke

interference when the

Electronic Clutch Actuator

is at the released position.

Input Shaft Spigot

Wear will not provide proper interface

with the inner race of the pilot bearing.

This can result in damage to the clutch

or the pilot bearing.

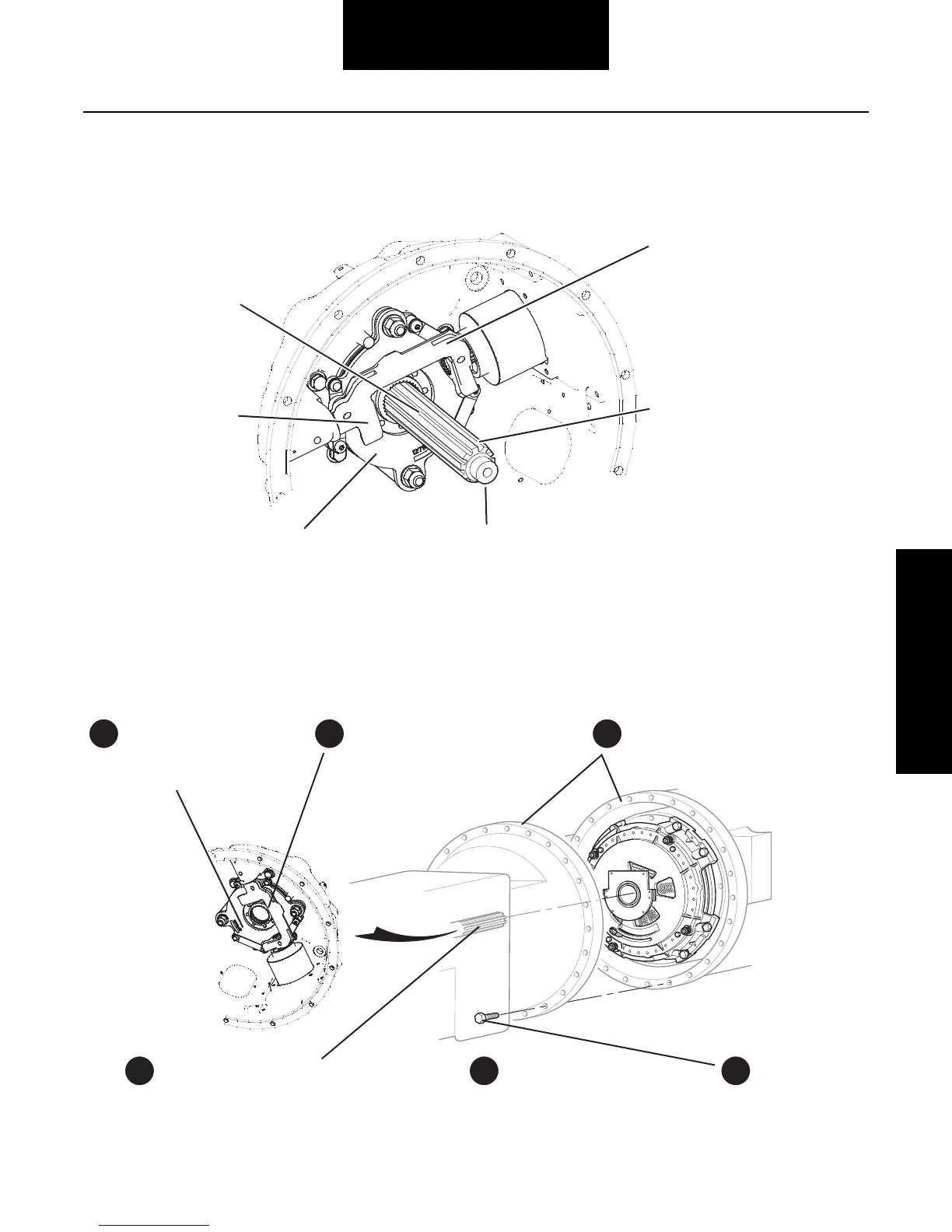

1

Put transmission in

neutral. Be sure new

LCIB has been installed.

3

Position transmission so

it is square to and aligned

with engine.

4

Mesh splines by moving transmission forward

and rotating the input shaft. Do not use

excessive force. Do not let the transmission

hang unsupported in the discs.

6

Install mounting

bolts and torque

to OEM specs.

2

Make sure that the yoke fingers

are rolled and remain in the up

position until they are over the

release bearing housing.

5

Before installing the mounting

bolts the lube tube will have

to be reconnected to the

clutch housing.

Generic graphic

Note: If the ECA has been removed, ensure the yoke fingers remain in the up position. Use the opening

vacated by the ECA to rotate the yoke in the up position just before the transmission is going to be aligned.

Loading...

Loading...