Install new pilot bearing.

1

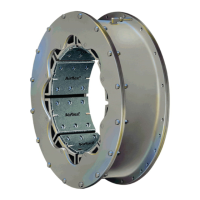

10.0" (7-spring & VCT Plus)

Measure the flywheel bore

to verify that the damper will

fit into the flywheel bore.

2

An assembled clutch weighs about 182 lbs (82 kg). Avoid the

risk of injury. Use proper equipment when lifting a clutch.

The intermediate plate is bolted to the

cover assembly and the rear driven

disc is held in place between the

pressure plate and intermediate plate.

DO NOT UNBOLT the intermediate

plate from the cover assembly.

Progressively tighten mounting

bolts in a crisscross pattern

starting with the lower left bolt

(1, 2, 3, 4, 5, 6, 7, 8). Torque to

40-50 lb-ft (54-68 N•m). Failure to

do this could result in improper

piloting of the clutch and cause

clutch damage.

7

Install lock washers and mounting

bolts (7/16" x 14 UNC x 2-1/4"

grade 5) finger tight. Replace studs

with lock washers and bolts.

6

Install second disc onto aligning

tool. Follow the orientation

instructions on the disc.

4

Insert aligning tool through

DM Clutch and rear disc.

3

Install two 7/16" x 14 UNC x 5"

studs into upper mounting holes.

Using clutch jack or other lifting

device, install assembled clutch.

5

2

6

4

8

7

3

5

1

Remove the

aligning tool.

10

Using a piece of 5/16" x 18

UNC x 3" threaded rod (jack

screw), install two nuts on

one end and lock them

together. This will allow you

to turn the jack screw in and

out of the cover assembly.

8

WARNING

Install the jack screw into one of the four

holes located adjacent to the clutch

mounting bolts. This forces the pressure

plate forward clamping the discs and holding

them in place. Be sure the hole chosen is at

the 6 o'clock position to allow for removal

after the transmission is installed.

9

Do not overtighten the jack screw.

Tightening more than 9 lb-ft can

cause permanent clutch damage.

CAUTION

WARNING

Loading...

Loading...