Prior to removing the transmission, rotate the engine

until one of the jack screw locations can be viewed

through the clutch housing inspection opening.

1

Using a piece of 5/16" x 18 UNC x 3"

threaded rod (jack screw), install

two nuts on one end and lock them

together. This will allow you to turn

the jack screw in and out of the

cover assembly.

2

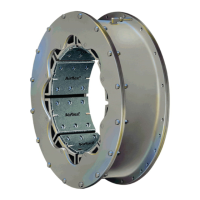

An assembled clutch weighs about 182

lbs (82 kg). Avoid the risk of injury. Use

proper equipment when lifting a clutch.

Do not overtighten the jack screw.

Tightening more than 9 lb-ft can

cause permanent clutch damage.

CAUTION

Remove the

jack screw.

6

Remove the transmission,

supporting its weight to

prevent damage to the

clutch discs.

4

Install the jack screw into one of the

four holes located adjacent to the

clutch mounting bolts. This forces

the pressure plate forward clamping

the discs and holding them in place.

3

Insert alignment shaft

and clutch jack.

5

Remove the old

pilot bearing.

8

CAUTION

Unbolt the clutch from the

flywheel and slide the clutch

away from the flywheel.

7

An assembled clutch weighs

about 182 lbs (82 kg). Avoid

the risk of injury. Use proper

equipment when lifting a clutch.

When removing the clutch, the

flywheel side disc can fall off of

the alignment shaft, permanently

damaging the driven disc.

WARNING

WARNING

Loading...

Loading...