39

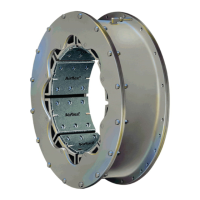

ECA Clutch

Lubricate

1. Open the inspection cover and verify the cross-shaft

and release bearing lube tubes are properly

attached and functional.

Note: Failed lube lines will prevent grease from reaching the

release bearing causing premature clutch release bear-

ing failure.

2. Apply grease through the release bearing lube tube

and continue to apply lube to cause enough grease

to purge out of the release bearing housing and

onto the transmission input shaft.

Note: Do not be concerned if excess grease gets onto the

LCIB friction surface, it will not affect the brake’s stop-

ping ability.

3. Apply grease to the cross-shaft bushing lube tube

so that a visual purge can be observed at the cross-

shaft bushing weep hole.

4. Reset the grease interval count if the optional auto-

mated lube schedule has been activated.

Note: See the “Grease Interval Count Reset” section.

IMPORTANT

Do not add lube (never seize or grease)

to the input shaft splines . The disc

must be free to slide.

CAUTION

Failure to properly lubricate the

bearing/bushing will result in bearing

and sleeve failures.

Grease

should purge

onto Input

Shaft.

Cross-shaft

Grease

Fitting

Release

Bearing

Grease

Fitting

Inspection

Cover

Cross-shaft

Bushing

Weep Hole

Cross-shaft

Lube Tube

Release Bearing

Lube Tube

Note: Zerk fittings are

labeled RS (Release Bearing)

and CS (Cross Shaft) on the

clutch housing case.

Note: All clutches use a lithium

complex grease with a minimum of

325°F (163°C) operating range

meeting NLGI grade 2 or 3 specs.

Loading...

Loading...