Use the Eaton Clutch Selector Guide (CLSL1511)

to make sure you have the right clutch.

An assembled clutch weighs about 150 lbs (68 kg).

Avoid the risk of injury. Use proper equipment

when lifting a clutch.

Progressively tighten mounting bolts

in a crisscross pattern starting with the

lower left bolt (1, 2, 3, 4, 5, 6, 7, 8).

Torque to 40-50 lb-ft (54-68 N•m).

Failure to do this could result in

improper piloting of the clutch

and cause clutch damage.

8

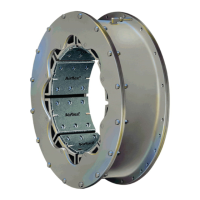

Install lock washers and mounting

bolts (7/16" x 14 UNC x 2-1/4"

grade 5) finger tight. Replace

studs with lock washers and bolts.

7

Install second disc onto aligning

tool. Follow the orientation

instructions on the disc.

5

Install intermediate plate into slots

on the clutch cover. Flywheel side

must face the flywheel.

4

Install disc onto aligning tool.

Follow the orientation

instructions on the disc.

3

Insert aligning tool

through bearing.

2

Note: When installing clutch to flywheel, position

the wear indicator at the bottom of flywheel

to ease future clutch servicing.

Install two 7/16" x 14

UNC x 5" studs into upper

mounting holes. Install

assembled clutch.

6

1

3

4

5

6

7

8

2

IMPORTANT

WARNING

Measure the flywheel bore.

Use the Eaton Clutch

Selector Guide to verify that

the damper will fit into the

flywheel bore.

7.0" (8-spring)

8.5" (10-spring)

10.0" (7-spring and Mack 9-spring)

Note: Mack 9-spring for Mack and Volvo

engines 2007 and newer only.

1

Loading...

Loading...