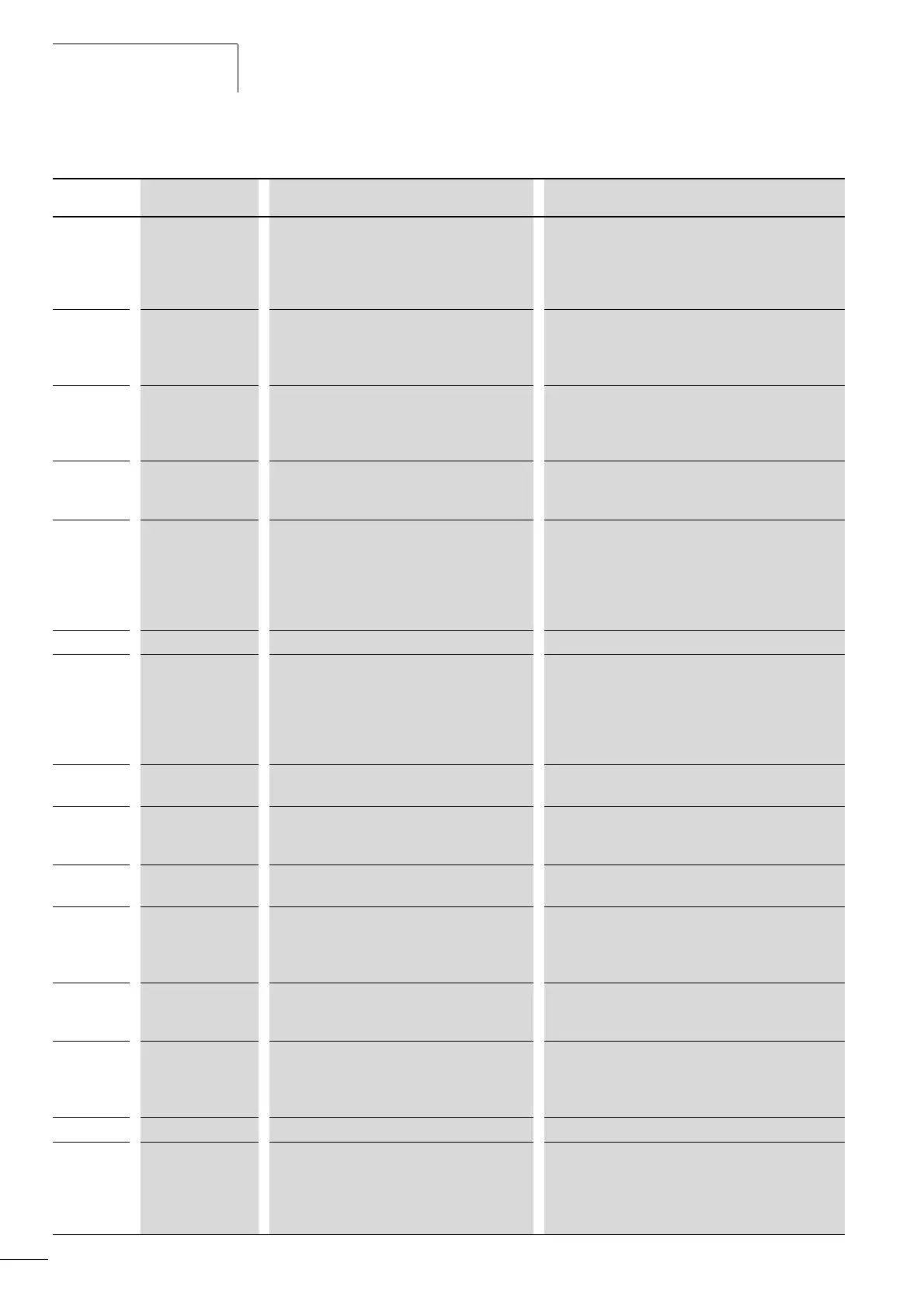

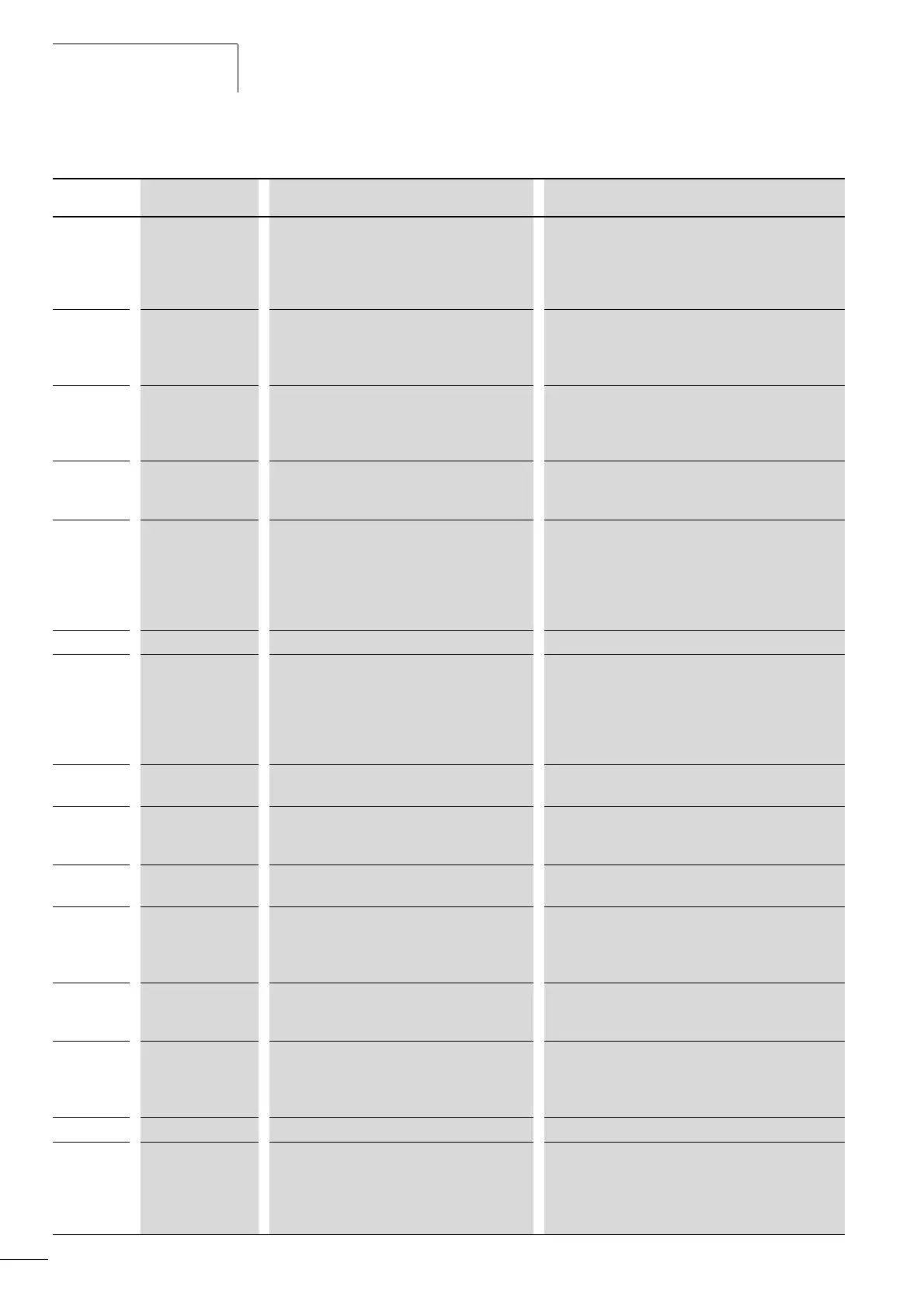

Error and Warning Messages

04/10 MN04020001Z-EN

64

Table 5: List of fault messages (F) and warning messages (AL)

Display

Designation Possible cause Instructions

01 Overcurrent • The frequency inverter has detected an exces-

sive current (> 4 × I

N

) in the motor cable.

• Sudden load increase.

• Short-circuit in motor cable.

• inadequate motor.

• Check the load

• Check the motor size

•Check the cable

(

h parameter P6.6)

02

Overvoltage • The DC intermediate circuit voltage has

exceeded the internal safety limit.

• the delay time is too short.

• high overvoltage peaks in line power

increase braking time

03

Ground fault • An additional leakage current was detected

when starting by means of a current

measurement.

• Insulation fault in the cables or in the motor

Check the motor cable and the motor

08 System fault • CPU error message

• Internal communication fault.

Reset error: Switch mains voltage off and on (Restart).

If the fault occurs again, please contact your closest

Moeller representative.

09

Undervoltage The DC intermediate circuit voltage has exceeded

the internal safety limit.

Probable cause:

• the supply voltage is too low,

• internal device fault,

• Power failure.

• If a brief power failure takes place, reset the fault and

restart the frequency inverter.

• Check the supply voltage. If it is OK, there is an internal

fault.

If this is the case, please contact your closest Moeller

representative.

13

Under-temperature The IGBT switch temperature is below -10 °C. Check the ambient temperature

14 Overtemperature The IGBT switch temperature is above 120 °C.

An excessive temperature warning is issued if the

IGBT switch temperature goes above 110 °C.

• Make sure that there is an unobstructed flow of

cooling air

• Check the ambient temperature

• Make sure that the switching frequency is not too high

in relation to the ambient temperature and to the

motor load

15

Motor blocked The motor blocking protection mechanism has

been triggered.

Check the motor

16

Motor over-tempera-

ture

The frequency inverter's motor temperature

model has detected motor overheating. The motor

is overloaded.

Decrease the motor load.

If the motor is not overloaded, check the temperature

model parameter.

17 Motor underload Motor idle, connection to load machine inter-

rupted (e.g. torn drive belt).

This function must be activated at P8.5. The overload

message is set at P8.12 and P8.13.

22

EEPROM checksum

error

• Error when storing parameters.

• Malfunction,

• Component fault,

• Error in microprocessor monitoring.

Please contact your closest Moeller representative.

25

Watchdog • Error in microprocessor monitoring.

• Malfunction,

• Component fault.

Reset the fault and restart

If the fault occurs again, please contact your closest

Moeller representative.

27

Back EMF Electromotive force

The voltage induced in the motor with the rotation

is greater than the output voltage of the frequency

inverter.

• The rotation energy is greater than the braking energy.

• Lengthen deceleration times.

• Switch on brake chopper and braking resistor.

• Use higher rated frequency inverters.

35

Application error The application is not working. Please contact your closest Moeller representative.

50

Live zero error

(Analog input)

Monitored zero point (4 mA, 2 V

h Parameter P2.1)

• Current less than 4 mA, voltage less than 2 V.

• Signal cable interrupted,

• The signal source is faulty.

Check the analog setpoint circuit and current and voltage

source (

h Parameters P8.10).

Loading...

Loading...