Parameters

04/10 MN04020001Z-EN

116

Braking (P12)

In parameter group P12 you can set different brake functions:

• DC braking,

• Generative braking (brake chopper),

• Mechanical braking (actuation).

The brake functions allow you to reduce undesired coasting and

long coasting times. Mechanical braking also ensures safe

operating states.

DC braking

With DC braking, the frequency inverter supplies the three-phase

stator winding of the three-phase motor with DC current. This

generates a stationary magnetic field which in turn induces a

voltage in the rotor while the rotor is in motion. As the electrical

resistance of the rotor is very low, even small induction can

generate high rotor currents and thus a strong braking effect.

As the speed decreases, the frequency of the induced voltage

reduces and therefore the inductive resistance also. The ohmic

resistance becomes more effective and thus increases the braking

effect. However, the generated braking torque drops off abruptly

before the rotor is at a standstill and disappears completely as

soon as the rotor movement has ended.

h

DC braking is therefore not suitable for holding loads. Nor

for intermediate braking. Once DC braking has been

activated, the motor comes to a standstill.

h

Caution!

Debounced inputs may not be used in the safety circuit

diagram. DC braking results in additional heating of the

motor. Configure the brake torque, set via braking current

(P12.1) and the braking duration (P12.2 and P12.4), as

low as possible therefore.

PNU ID Access right

RUN

Value Description Factory setting

(P1.3)

P12.1 507 - DC braking, current I

e

Set value for the DC current, which supplies the motor during the

DC braking.

The value depends on the rated operational current I

e

of the

frequency inverter: 0.2 x I

e

– 2 x I

e

[A]

The parameter is only active, if a value > 0 has been entered for

P12.2 or P12.4.

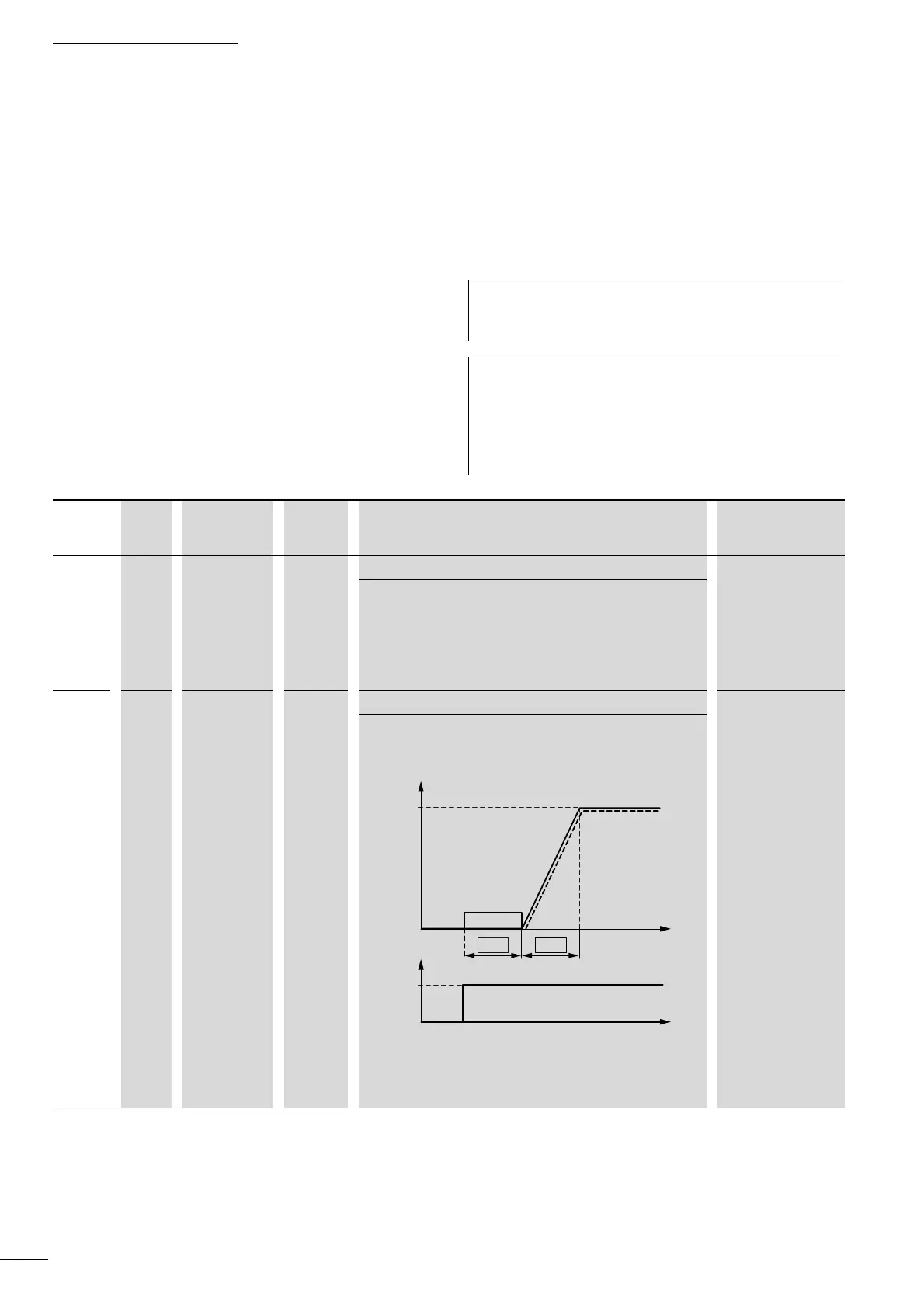

P12.2 516 - DC braking, braking time at start 0.00

0.00 - 600.00 s

The braking time of the DC braking c is activated with the start

command (FWD, REV).

After the time set here has elapsed, the frequency inverter starts

automatically with the acceleration time set at P6.5. The speed of

the motor b follows the characteristic of the output frequency a.

f

t

f

out

P12.2

f

t

P6.5

FWD

REV

a

b

c

Loading...

Loading...