Do you have a question about the Edwards APG200 and is the answer not in the manual?

Explains warning, caution, and notice symbols and their meanings.

Details the safety symbols used on the product and documentation.

Overview of the APG200 Pirani gauge and its key features.

Explains how to configure and identify the product by its part number.

Specifies the environmental limits for operation and storage.

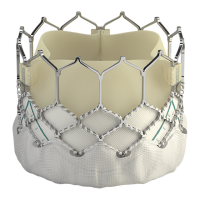

Lists materials used in the gauge construction, especially for vacuum exposure.

Details the accuracy and pressure ranges for different filaments.

Provides physical dimensions, enclosure rating, and flange sizes.

Specifies the ID resistor values for different configurations.

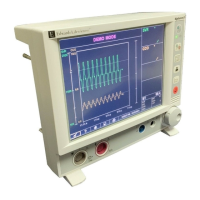

Details voltage output characteristics and error voltages.

Outlines setpoint adjustment ranges and hysteresis.

Instructions for receiving, checking, and storing the gauge.

Guidelines for physically mounting the gauge in the system.

Details methods for connecting the gauge to the vacuum flange.

Explains electrical connection procedures and precautions.

Specifies limits for electrical cable length based on voltage.

Explains the meaning of LED status lights during operation.

Provides formulas for converting log linear voltage to pressure.

Illustrates pressure-voltage variations for different outputs.

Provides tables for converting non-linear voltage to pressure.

Explains how different gases affect readings and conversion factors.

Step-by-step guide to adjusting setpoint thresholds.

Describes error indications and their meanings.

Procedures for baking the gauge in UHV applications.

Steps to adjust the gauge at atmospheric pressure.

Steps to adjust the gauge at low pressure conditions.

Performing adjustments remotely via electrical connector.

Instructions for replacing the sensor tube and subsequent adjustment.

Troubleshoots issues where the LED indicator does not illuminate.

Diagnoses and resolves inaccurate pressure readings.

Addresses issues related to calibration errors.

Troubleshoots problems related to a broken filament.

Safe and compliant methods for disposing of the equipment.

Information on how to order replacement components.

Lists available cables suitable for the gauge.

Procedures for returning the unit for repair or service.

Detailed visual guide to using the multi-function button.

| Category | Medical Equipment |

|---|---|

| Manufacturer | Edwards |

| Model | APG200 |

| Storage temperature | -20 to 70 °C |

| Output signal | 0-10 Vdc |

| Type | Pirani Gauge |

| Application | Vacuum measurement |

| Accuracy | ±15% |

| Power Supply | 24 V DC |

| Materials exposed to vacuum | glass |