4. Mount the gauge tube in verc

al direcon to minimise the build up of process

parculates and condensable vapours within the gauge.

5. For precision, we recommend that the atmosphere and vacuum adjustment must

be done before use. Refer to Maintenance on page 36.

4.3 Connect the gauge

4.3.1 Connect to the vacuum system

To connect the gauge to the vacuum system:

▪ Use an O-ring or a centring-ring or a co-seal to connect the gauge with NW16 or

NW25 ange to a similar ange on the vacuum system. The gauge is not

compable with centering ring adaptors.

▪ Use a new copper gasket to connect the gauge with a DN16CF ange and a new

face seal metal gasket to connect the gauge with a 8VCR or 4VCR ange to a similar

ange on the vacuum system.

▪ Apply 2 to 3 turns of 6 mm or 1/4” wide PTFE tape to a gauge with an 1/8” NPT

ange. Begin at the start of the thread and wrap in the direcon of the threads to

make sure that the seal is leak ght.

▪ Make sure that the vacuum system has a correct earth (ground) connecon.

▪ Connect the tube of the gauge to the vacuum system.

4.3.2 Connect to the electrical equipment

CAUTION: GAUGE MALFUNCTION

Risk of damage t

o equipment. Do not make connecons to the gauge idencaon

pin. Failure to do so can cause the gauge to malfuncon.

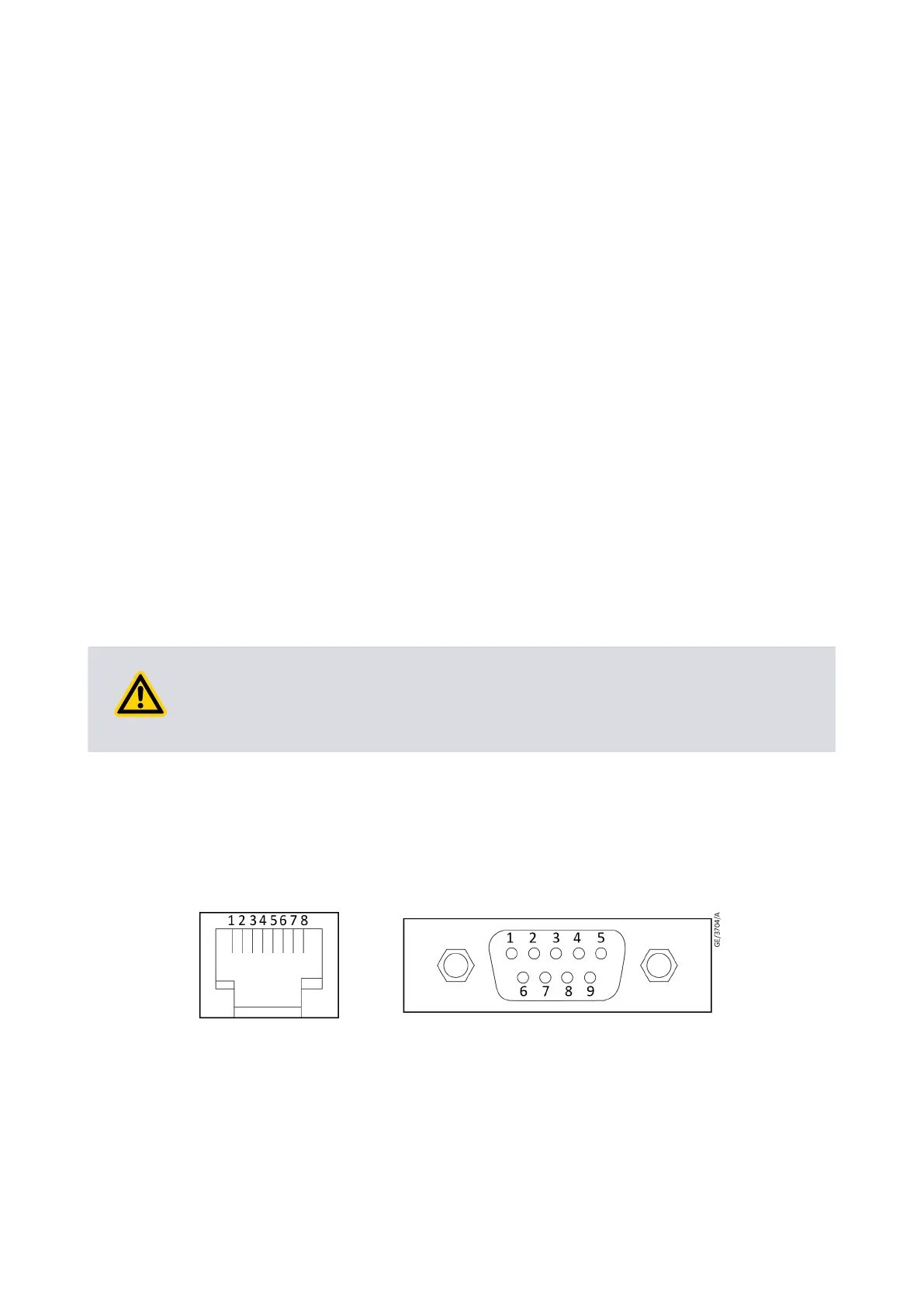

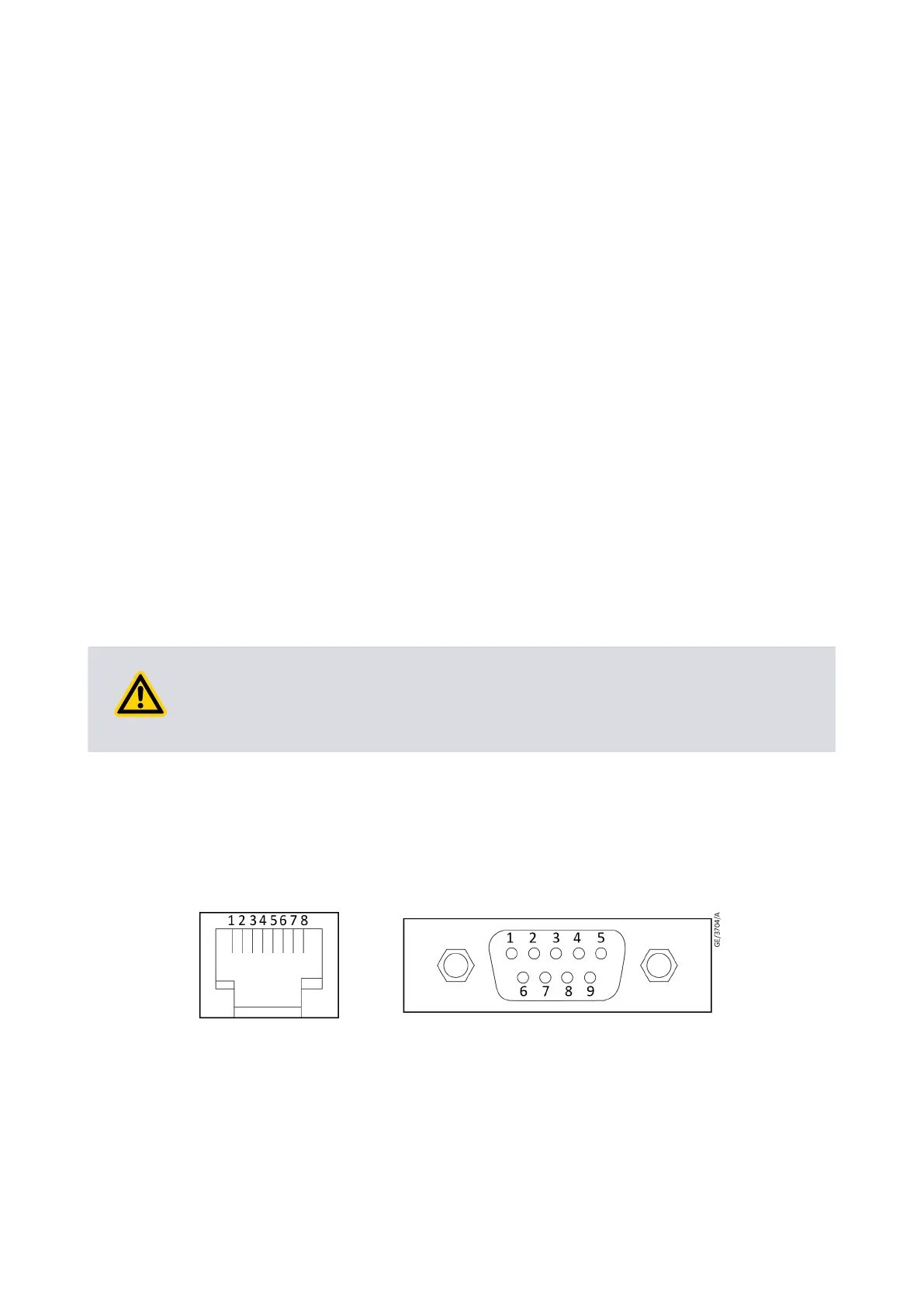

Refer to Figure: Rec

ommended electrical connecons for schemac diagram of the

electrical connecons to the gauge. Use the pins on the electrical connector as shown in

Table: Pins on the APG200 electrical connector.

Refer to Technical data on page 12 for more specicaons.

Figure 5 Electrical connectors

07/2021 - ©Edwards Limited

Page 18D1G0000880_A

D1G0000880_A - Inst

allaon

Loading...

Loading...