06/2016 - Art. Nr. 4200 1041 1103A 13

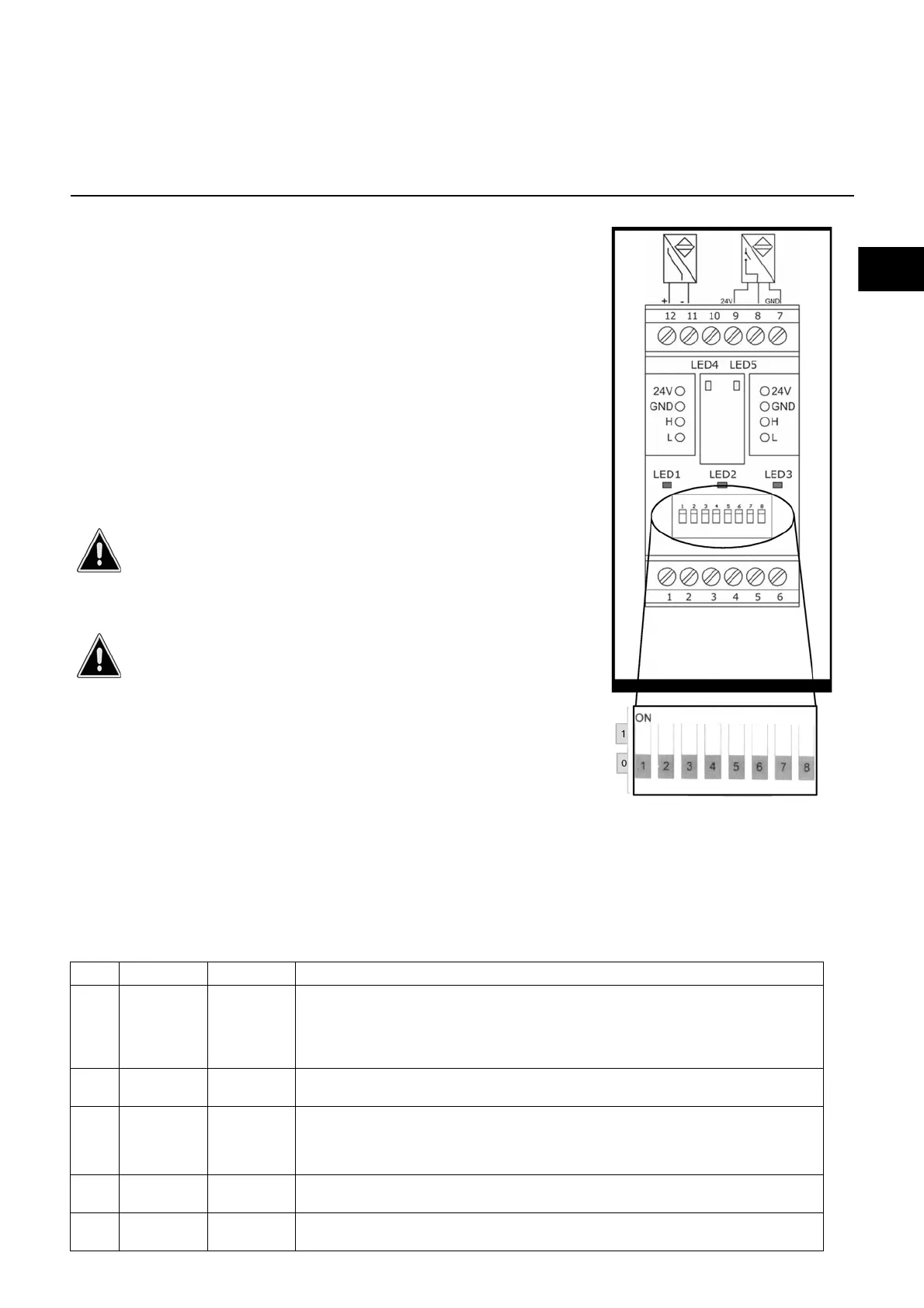

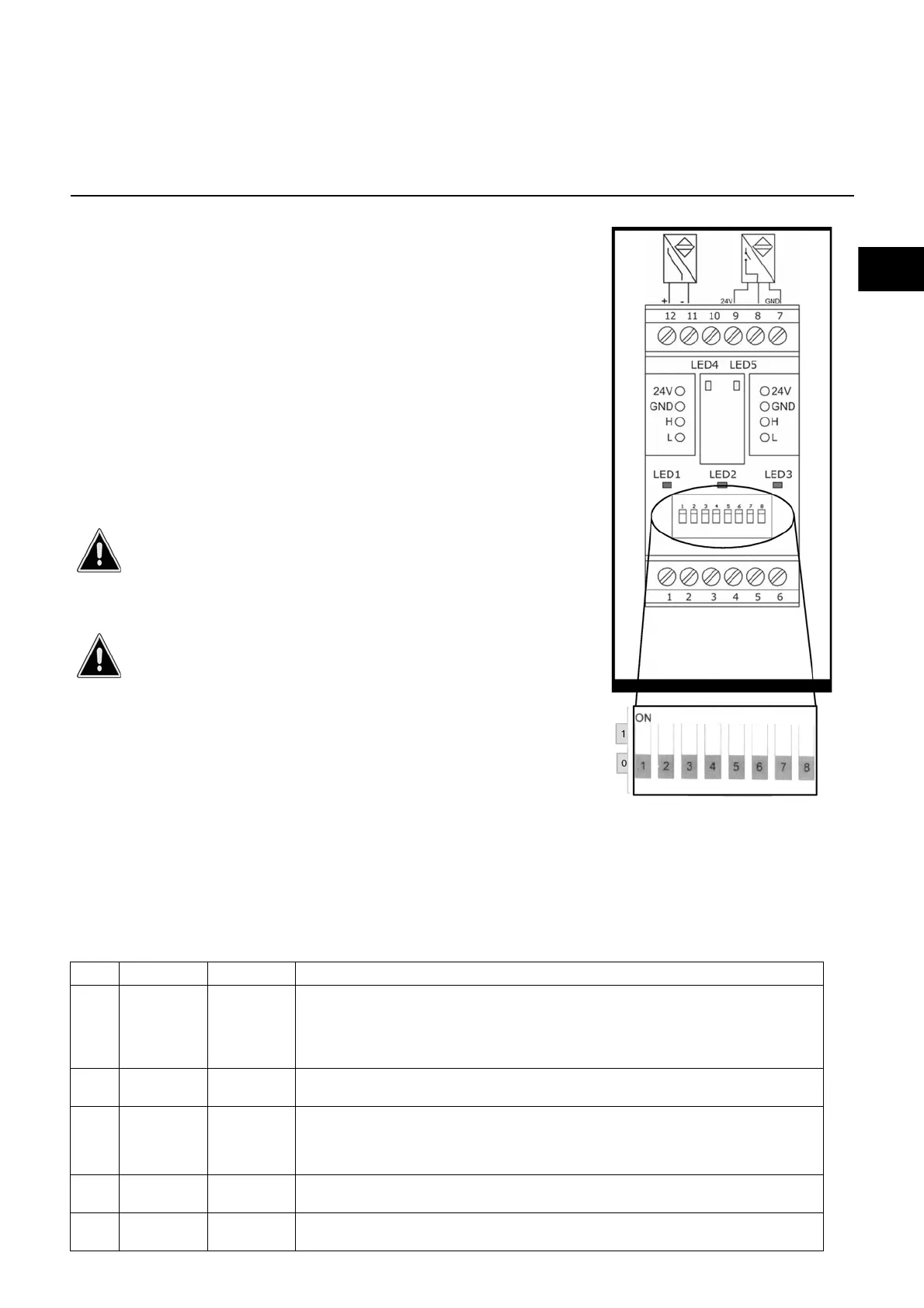

VSM100

Raccordement, voir le

schéma des connexions

Commutateur

DIP

Function

VGx MV/TC burner

Speed control – VSM100 module

Module description

The VSM100 allows the BurnerTronic to control the speed of the

fan motors. The BurnerTronic treats the VSM100 as an additional

compound channel. This allows you to freely define the speed

over the entire load range. The VSM100 is connected to the

BurnerTronic via LSB. The VSM100 delivers the speed setpoint

to the motor driver (frequency converter or the like) as a 0/4–

20mA or 0–10V signal. The VSM100 records the actual speed

and sends it back to the BurnerTronic for monitoring purposes.

Either Namur sensors or 3-lead sensors with a switch output can

be used to record the speed. Feedback via a 0/4 – 20mA current

loop is also possible.

Note: it is only possible to use the VSM100 module in connection

with the LCM100 module.

Note: burners which are equipped with the VSM100 module in

the factory are preset so that the module can be used. Usually,

module settings or configuration of the BurnerTronic are not

required.

Modifications are the responsibility of the operator if a

configuration is selected which deviates in a circuit

diagram of the factory settings. The operator must

ensure that his settings are correct in that it is safe to

operate the burner. Modifications may only be carried

out by qualified trained personnel.

Incorrect setting of the DIP switches can lead to

malfunctions. Before commissioning, the setting

(DIP switch) of the LCM100 module must be checked

according to the circuit diagram. If the DFM300 is

the last device in the CAN bus chain, switch number

1 must be set to 1 (ON). The settings according to the

circuit diagram must be adhered to.

You can configure the BT3xx for the VSM100 module using the

PC software. The settings are made using parameters 403 to

406. Information on the individual parameters can be found in the

parameter list 4200 1018 1501.

LED displays

The VSM100 has 5 LEDs, enabled as follows

Pos. LED Colour Meaning

1ERR

(LED 1)

red The LED is switched off in normal operation. It illuminates under the following

conditions:

- Initialization not yet or not successfully completed (for example, because HW

could not be initialised)

- No message has been received for at least 3 seconds

2PWR

(LED 2)

green On: Module operating normally = completely initialised and without fault

3CAN

(LED 3)

green Off: CAN controller in Bus Off. Communication is not possible

Flashing: CAN controller has determined temporary faults.

The LED continues flashing for a time after the problem has been rectified.

On: CAN is ready for operation

4 Namur

(LED 4)

yellow Flashing: LED toggles whenever a pulse is received at the

Namur input. The LED flashes at half the pulse frequency

5 3-lead

(LED 5)

yellow Flashing: LED toggles whenever a pulse is received at the

Namur input. The LED flashes at half the pulse frequency

Loading...

Loading...