06/2016 - Art. Nr. 4200 1041 1103A 17

Installation

Gas train

Accessories (for PED option)

Gas train installation

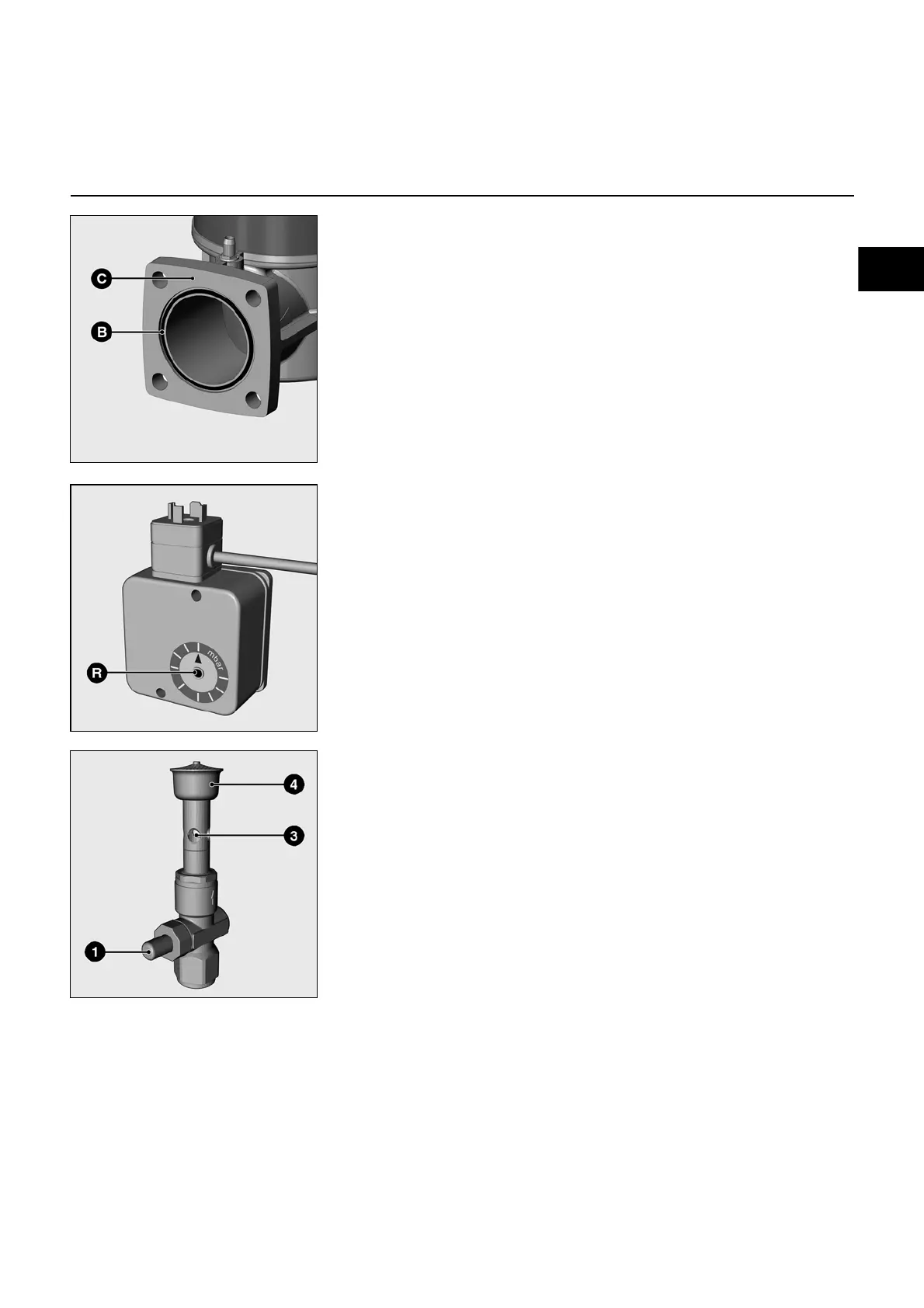

• Check the correct position of the

O-ring B in the gas connecting

flange C.

• Secure the gas train with M10 nuts so

that the SKP regulator or the coils of

the MBC-SE are positioned

perpendicular to the gas train.

• Pay attention to the direction of

circulation.

• Connect the power cable to the gas

train.

Test burner

Depending on the country-specific

requirements, when installing steam

boilers it may be necessary to fit a test

burner to the gas train (e.g. in line with

the Pressure Equipment directive TRD

412). This is used to vent the gas control

system.

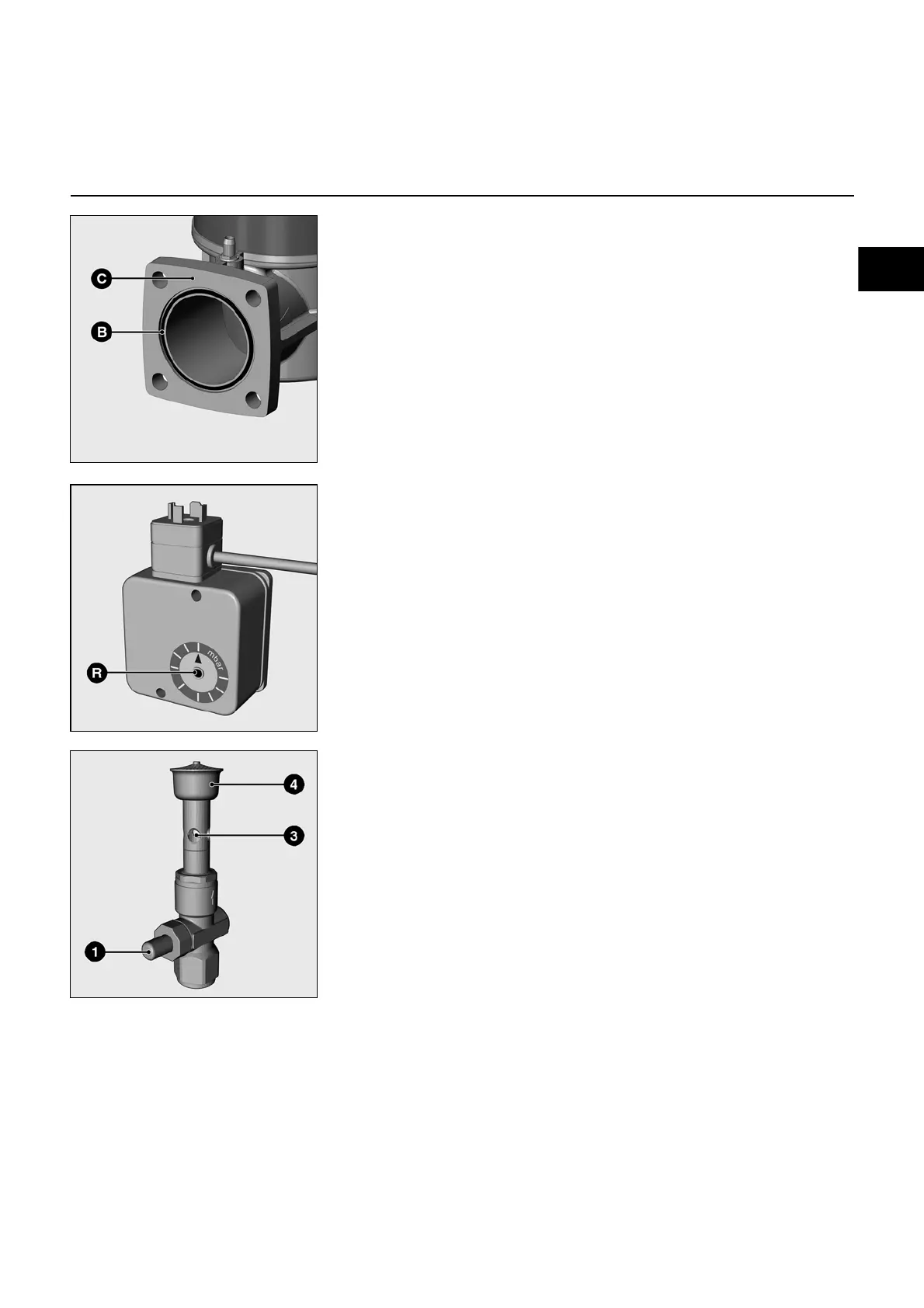

The gas supply is switched on by

pressing the button (1). The flow of gas

brings in the required amount of

combustion air via the hole in the burner

tube (3). The gas/air mixture is routed

towards the burner head (4) and ignited

manually at its opening. Gas is supplied

for as long as the button is pressed and

cut off when it is released.

Technical data:

• Type of gas:

gases in accordance with DVGW

worksheet G 260/1, gas families 1, 2, 3

• Ambient temp.: -15°C to +70°C

• Installation position: vertical, facing

upwards

• Operating pressure to: 500 mbar

NEW IMAGE

y403899.jpg

NEW IMAGE

y403899.jpg

NEW IMAGE

y403899.jpg

Max. gas pressure switch

The gas pressure switch is used to

control gas pressure. The pressure

switch is installed here in order to

monitor pressure increase (maximum

value recommended for installations

implemented according to standard

TRD 604).

The setpoint (switching point) is set on a

rotary scale.

Loading...

Loading...