06/2016 - Art. Nr. 4200 1041 1103A16

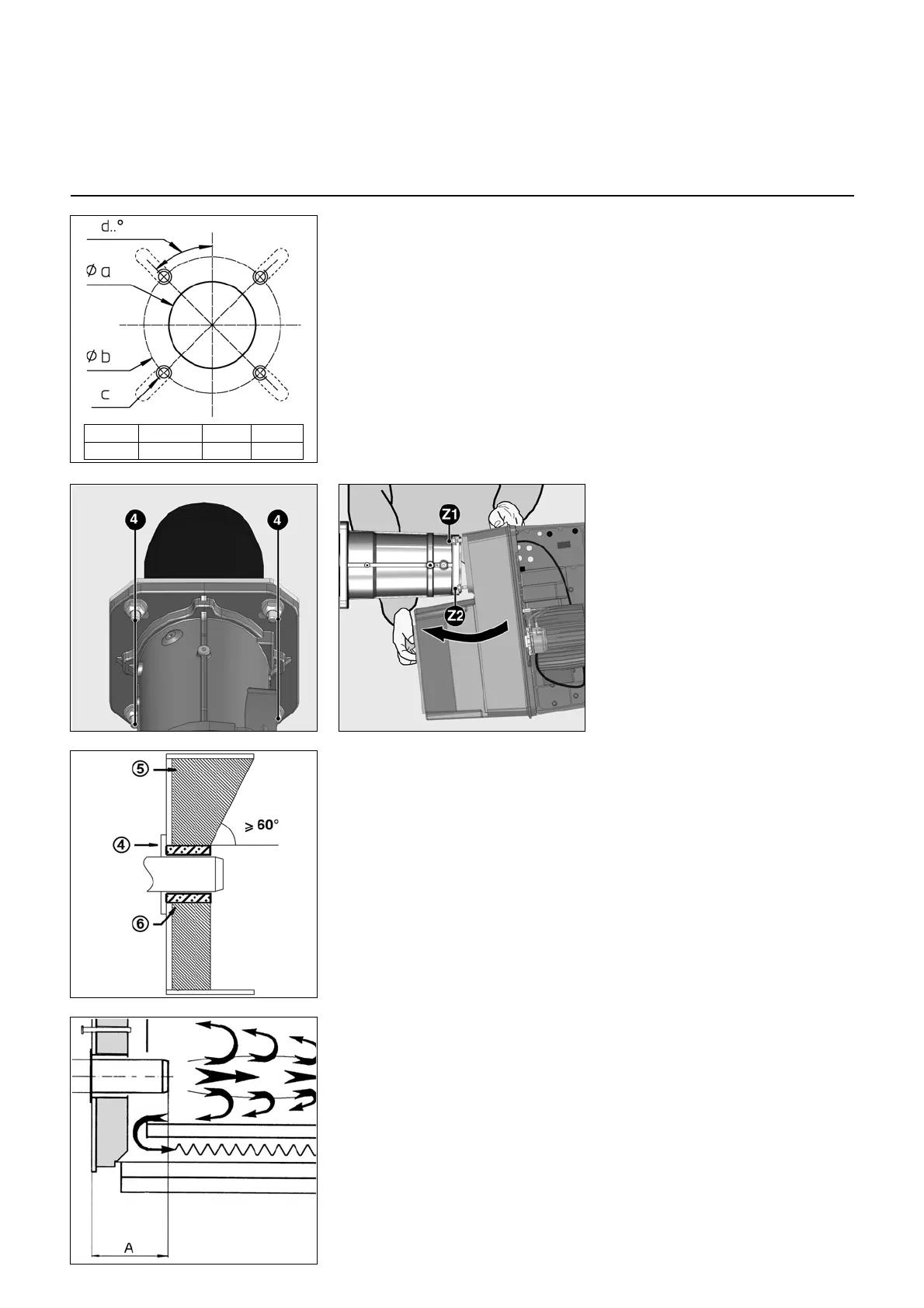

Ø a Ø b c d

195 220-260 M10 45°

Installation

Burner installation

Preparing the boiler front

• Prepare the burner mounting plate/

boiler door in accordance with the

diagram.

• Establish the internal diameter a of

195 mm.

• To mount the burner head bracket,

drill four M10 holes (drill diameter 220

to 260 mm) as shown in the diagram

opposite.

Burner head assembly

• Screw the bolts into the burner fixing

plate/boiler door and position the

insulating seal. For a drill hole of

< 260 mm, the elongated slots in the

gasket should be cut to the required

dimensions.

• Remove the combustion components

from the head.

• Attach the burner head with 4 nuts

(ref. 4). At this point, check that the

gas connection flange is correctly

positioned (on the left or right).

Burner tube installation depth and

brickwork surround

Unless otherwise specified by the boiler

manufacturer, heat generators without a

cooled front wall require brickwork or

insulation 5 as shown in the illustration

opposite. The brickwork must not

protrude beyond the leading edge of the

flame tube, and should have a maximum

conical angle of 60°. Space 6 must be

filled with an elastic, non-flammable

insulation material.

The furnace pressure take-off pipe pF

must not be clogged.

Exhaust gas evacuation system

To avoid unpleasant noise emissions,

right-angled connectors should not be

used on the flue gas side of the boiler.

On boilers with reverse firing, the

minimum flame tube insertion depth A

should be observed as per the boiler

manufacturer's instructions.

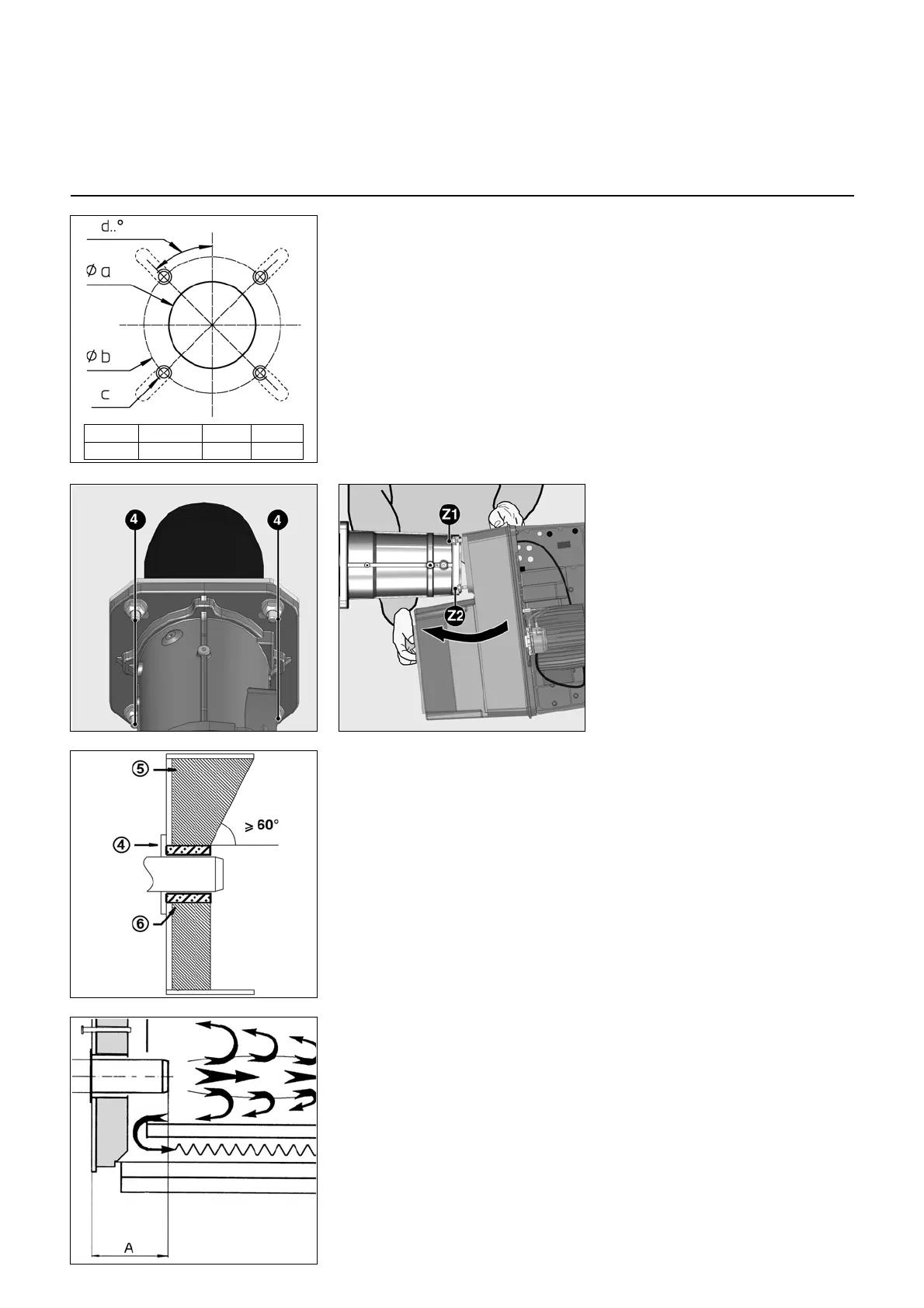

Fitting the burner body

• On the burner body, fully unscrew the

two upper nuts Z1 and remove the two

lower nuts Z2.

• Place the burner housing sloping

diagonally forwards and fit the two upper

bolts into the two slots in the burner

attachment head.

• Rest the burner body on the spacer and

tighten the four nuts.

• If necessary, the body can be fitted with

the volute casing upwards. In this case,

proceed in the opposite direction to

fitting.

The body cannot be positioned in any

other way.

For assembly in the position with

the volute facing upwards, unclip

the display, turn it over 180°, and

refit it.

Loading...

Loading...