06/2016 - Art. Nr. 4200 1041 1103A20

Installation

Electrical connection

Checks before commissioning

Checks before commissioning

The following must be checked before

initial commissioning:

• That the burner is assembled in

accordance with the instructions given

here.

• That the burner is pre-set in

accordance with the values in the

adjustment table.

• Setting the combustion components.

• The heat generator must be ready for

operation, and the operating

regulations for the heat generator

must be observed.

• All electrical connections must be

correct.

• The heat generator and heating

system must be filled with water and

the circulating pumps must be in

operation.

• The temperature regulator, pressure

regulator, low water detectors and any

other safety or limiting devices that

might be fitted must be connected and

operational.

• The exhaust gas duct must be

unobstructed and the secondary air

system, if available, must be

operational.

• An adequate supply of fresh air must

be guaranteed.

• The heating request must be

available.

• Sufficient gas pressure must be

available.

• The fuel supply lines must be

assembled correctly, checked for

leaks and bled.

• A standard-compliant measuring point

must be available, the exhaust gas

duct up to the measuring point must

be free of leaks to prevent anomalies

in the measurement results.

General regulations applying to the

gas connection

• The gas train must only be connected

to the gas mains by a recognised

specialist.

• The cross-section of the gas line

should be of a size designed to

guarantee that the gas flow pressure

does not drop below the specified

level.

• A manual shut-off valve (not supplied)

must be fitted upstream of the gas

train.

• In Germany, a thermally triggered

shut-off valve (to be installed by the

customer side) must be fitted as

specified by the draft combustion

ordinance.

It is the responsibility of the fitter or his

representative to obtain approval for the

system at the same time as the burner is

commissioned. Only the fitter or his

representative can guarantee that the

system meets applicable standards and

regulations. The fitter should be in

possession of the corresponding official

permit, and should carry out the

corresponding sealing tests and purge

the system of air.

All electrical installation and

connection work must only be carried

out by a suitably qualified service

engineer. N.B.: The applicable

guidelines and directives must be

observed, as well as the electrical

circuit diagram supplied with the

burner.

Electrical connection

• Check to ensure that the power supply

is as specified (230V, 50 Hz single-

phase current with neutral and earth).

Boiler fuse: 6.3A

It must be possible to disconnect the

burner from the mains using an

omnipolar shutdown device complying

with the standards in force.

A device to protect against short circuits

must also be fitted upstream of the

burner's electrical power supply.

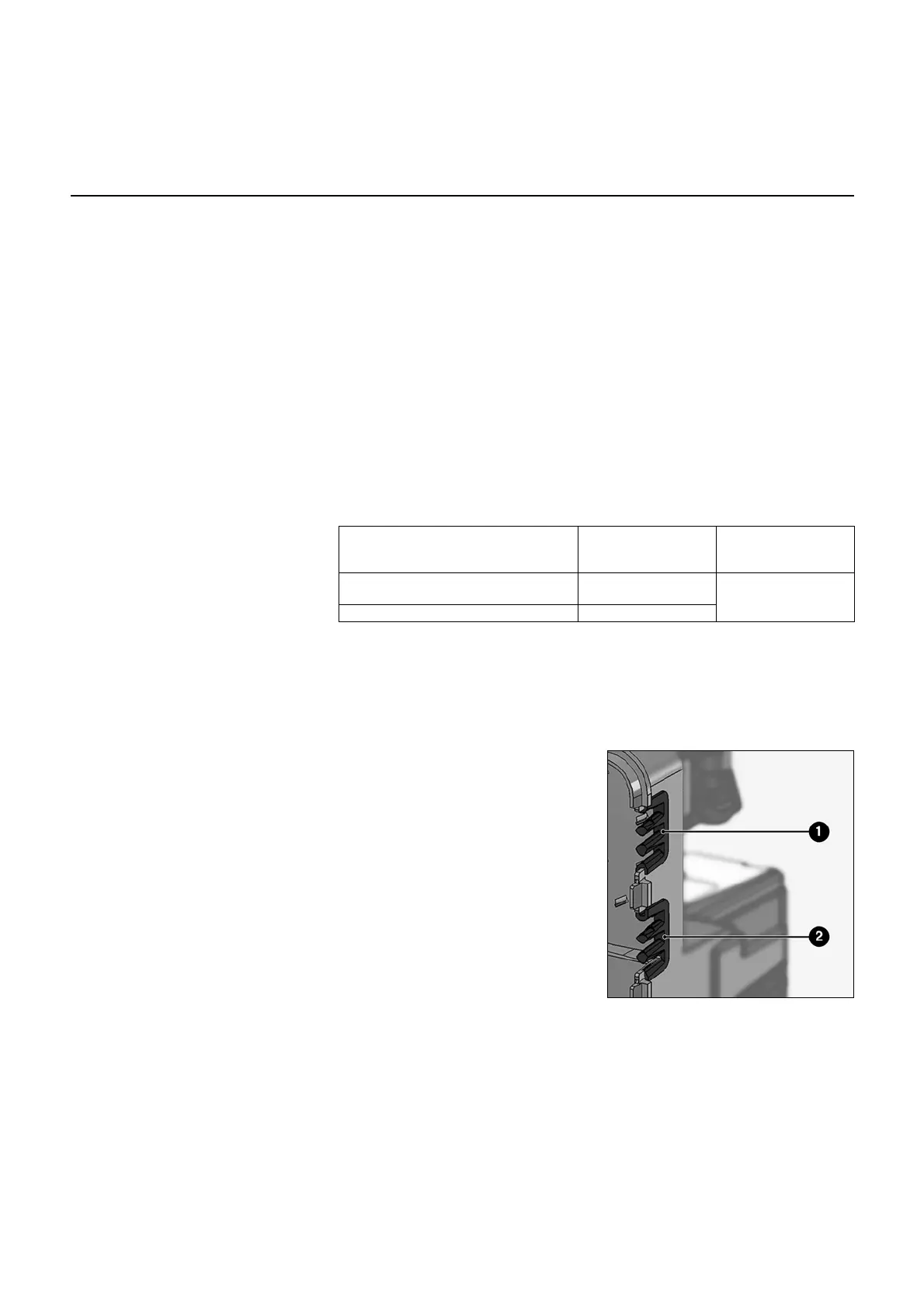

The connection cables for the burner

motor, the control voltage and the gas

train are fixed and routed through cable

grommets 1 and 2. They must be

connected to the terminal in accordance

with the electrical circuit diagram.

To this end, the following conductor

cross-sections must be observed:

Burner motor connection

The burner is supplied for a mains

supply voltage of 400V-50Hz, three-

phase current with a neutral wire and

earthing.

• Check the direction of rotation of the

fan motor via manual activation of the

burner protection device.

Connect the gas train using the

connectors supplied with the burner

(black to black, grey to grey).

Minimum

cross-section

[mm²]

Maximum

cross-section

[mm²]

Single-phase power supply

(control voltage)

1.5

4

Three-phase power supply (fan motor) 2.5

Loading...

Loading...