Rosemount Model 1195/ProPlate/Mass ProPlate

6-30

NOTE

To comply with A.G.A. Report No. 3, the primary element must be

“Orifice, Flange Taps, AGA 3.”

12. Define Primary Element Information:

a. Enter the Primary Element minimum diameter. The Primary

Element minimum is the bore size. See Figure 6-24.

b. Enter Primary Element Material.

c. Enter Meter Tube Diameter (pipe ID) and units at

reference temperature. This is dimension B.D. in Figure 6-24.

d. Enter Meter Tube Material.

13. Enter Operating Conditions.

a. Enter Operating Pressure Range and Units.

b. Enter Operating Temperature Range and Units. The

operating temperature range points must be equal to or

greater than the saturation temperature at the given

operating pressures.

14. (Optional) If desired, modify standard pressure and/or

temperature conditions.

15. Select Next.

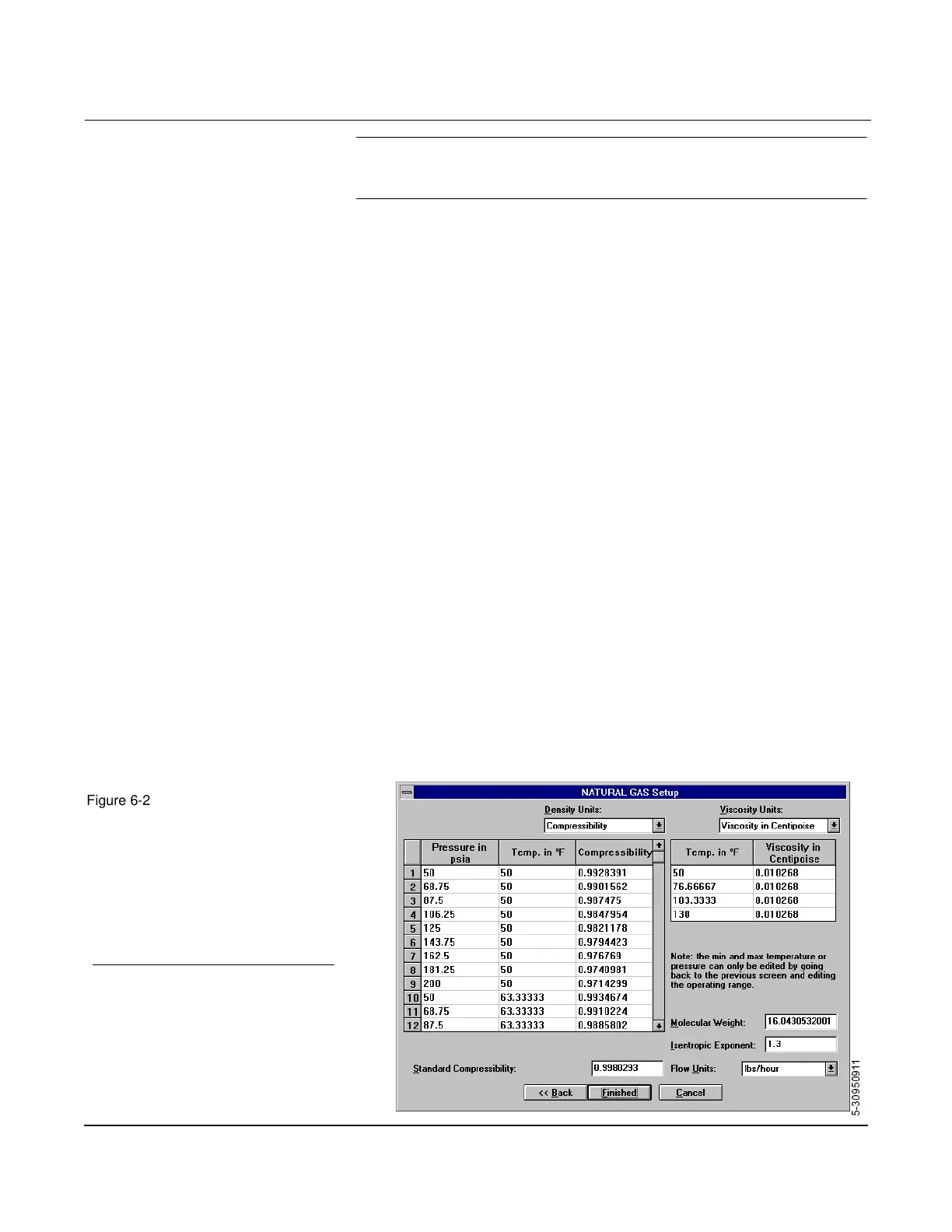

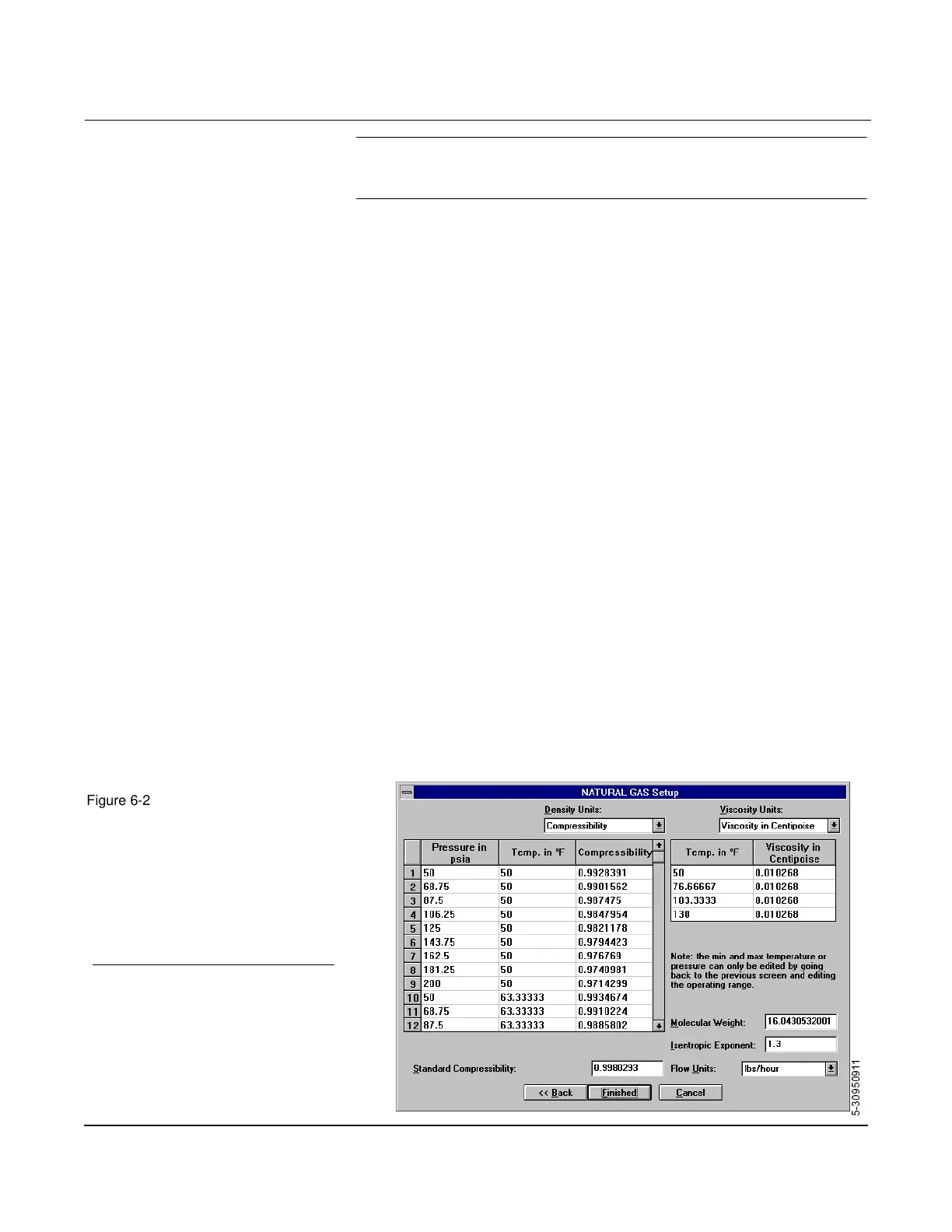

16. The displayed values are calculated per A.G.A. 8.

If desired, all data fields can be edited. However, if a change is

made to either a density or viscosity value, the EA considers the

fluid to be “Custom Fluid.”

Data fields should conform to density or compressibility factor

information as published by A.G.A. 8. (A.G.A. 3 recommends

viscosity values of 6.9 ⫻ 10

-6

pounds mass per foot-second or

0.010268 centipoise. Another available reference is the Gas Orifice

Flow Program published by the Gas Research Institute.

Figure 6-25.

Compressibility and Viscosity Table

(Steam Configuration).

NOTE

Table values automatically

convert if a different unit of

measure is selected.

Loading...

Loading...