PlasmaQuant MS product family Optimizing hardware

63

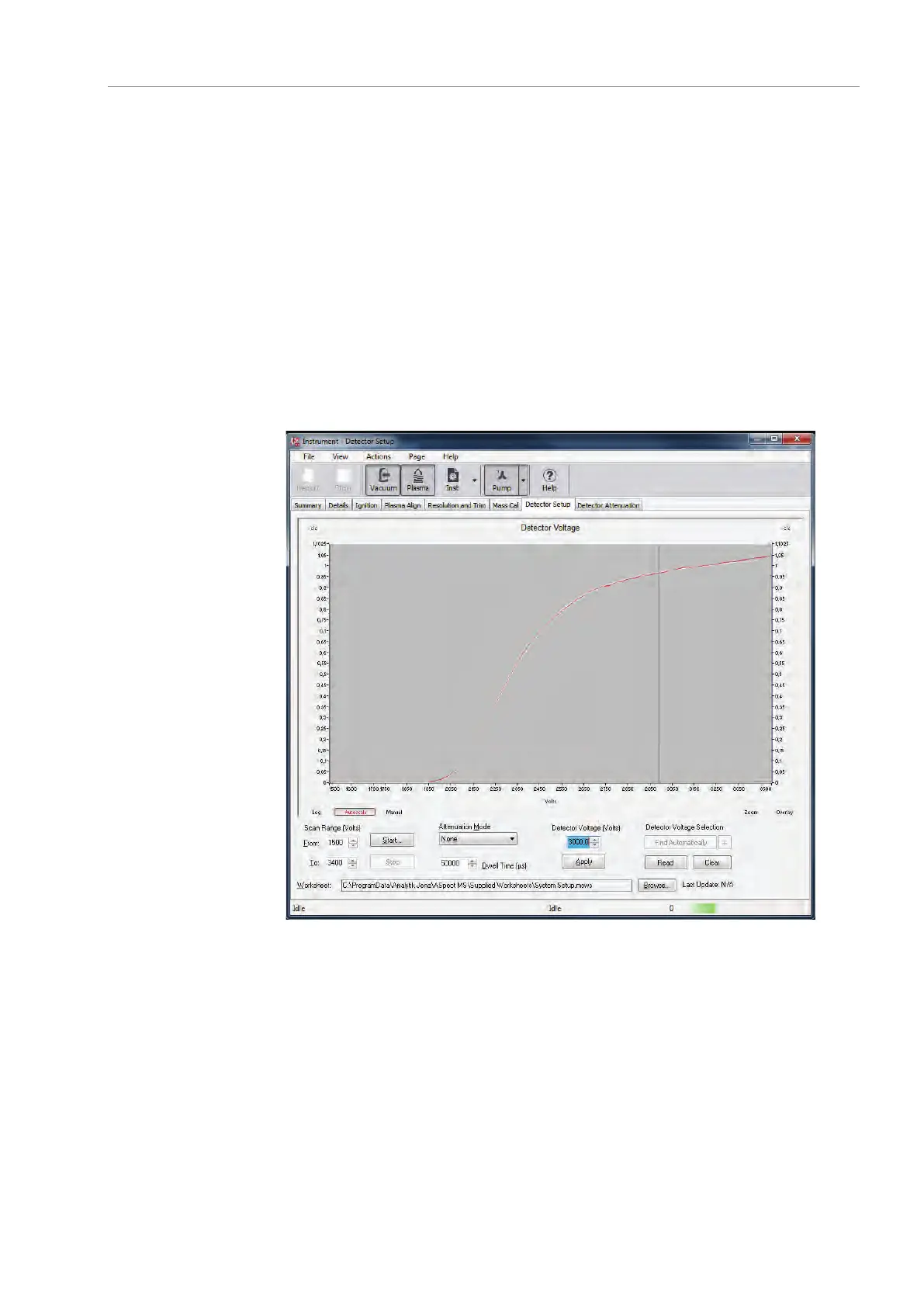

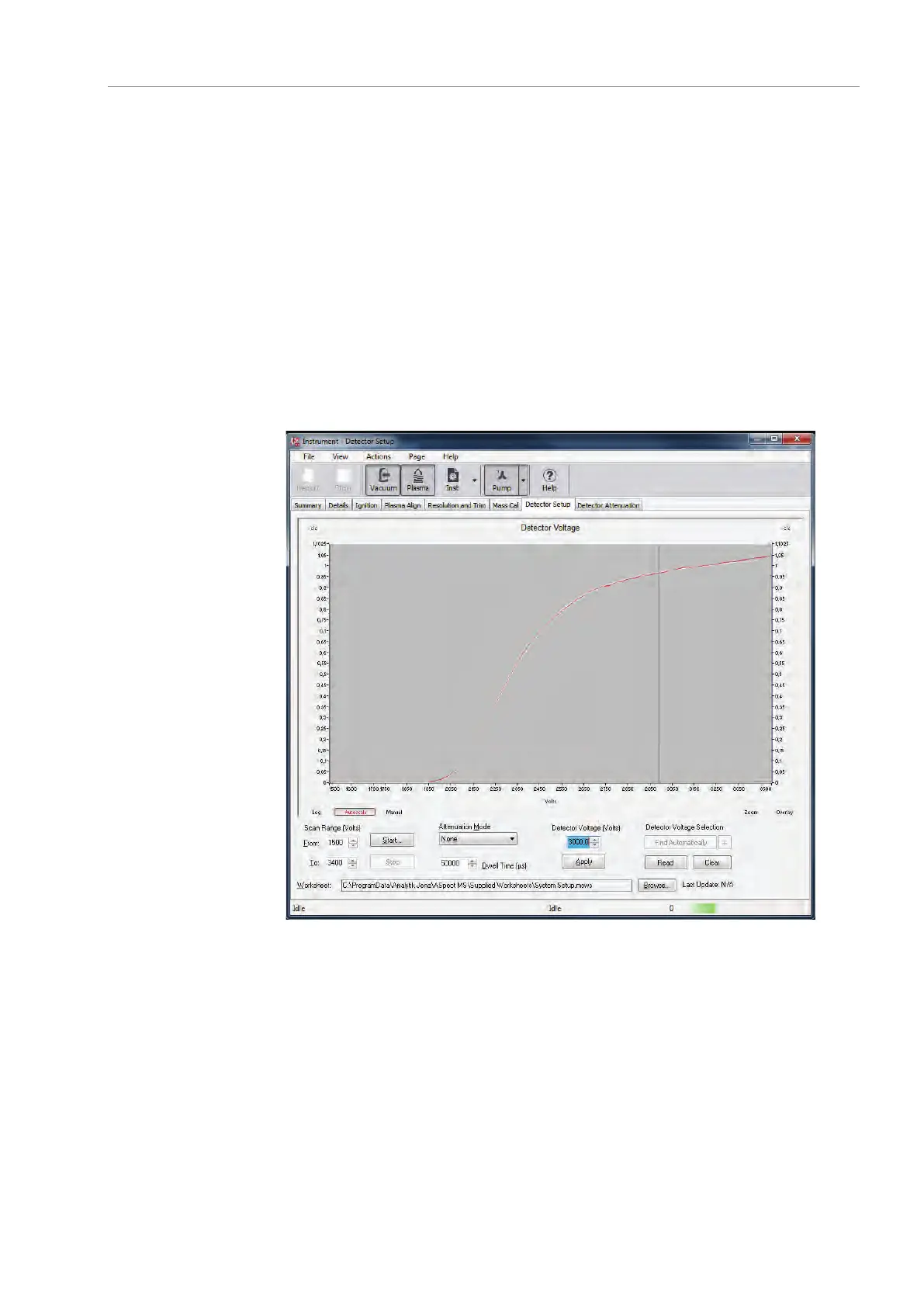

6.5 Detector voltage

Over time, and with continued use, the detector “ages” and requires increased voltage

to produce the same signal level from a given concentration of sample. Check the

detector voltage weekly and keep the voltage set to the optimum.

The software scans the detector voltage across the specified range, and recommends

the ideal set point. When the detector voltage nears its maximum setting of 4 kV, the

detector needs to be replaced.

If you do a detector scan and the new recommended voltage is within ~200 V of the

previous setting, there is no need to change it. You can also repeat the detector scan

more than once to ensure the set point is reproducible. Make note of the current

detector voltage set point before doing a scan, so you can return to that if the software

chooses a slightly different value.

Fig. 30 Detector voltage calibration

If the From/To voltages are too close together or too far apart, an error message will

be generated. There must be enough scan range to create an S-shaped curve without

over-ranging, and the From/To voltage ranges may need to be adjusted. Typically, as

the detector ages, the voltage range needs to be changed to obtain an accurate scan.

1. Aspirate the 1 µg/L (1 ppb) tuning solution.

2. On the I

NSTRUMENT window, click the DETECTOR SETUP tab.

3. Ensure that N

ONE is selected in the ATTENUATION MODE drop-down menu for the

manual mode.

4. Set the D

WELL TIME for 50,000 µs.

Loading...

Loading...