Cerabar PMP21 IO-Link System integration

Endress+Hauser 21

8 System integration

8.1 Process data

The measuring device's process data are transmitted cyclically as per SSP 4.3.1

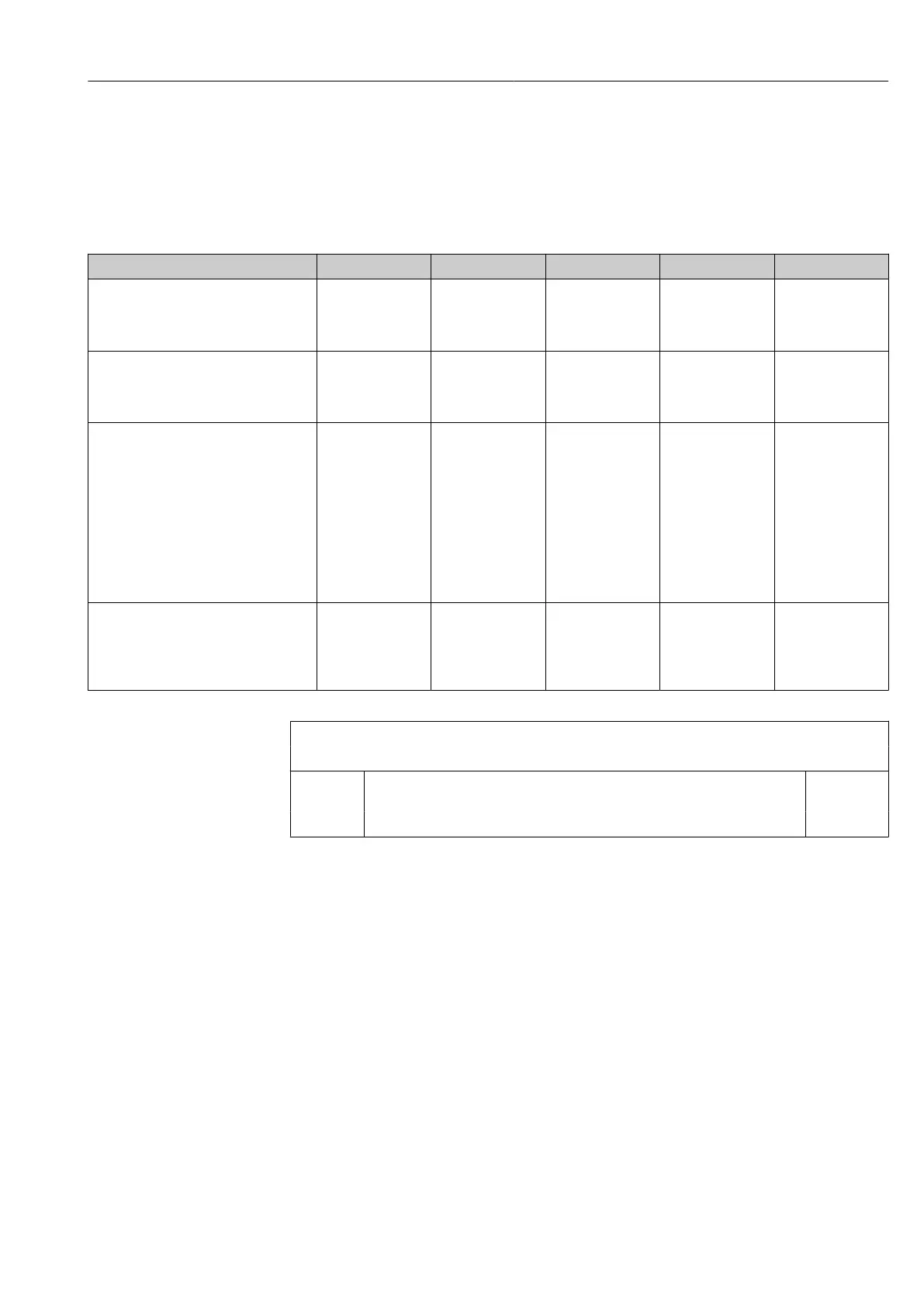

Bit-offset Name Data type Permitted values Offset/gradient Description

0 Process Data

Input.Switching

Signal Channel 1.1

Pressure

1-bit Uinteger 0 = False

1 = True

- Switching signal

status SSC 1.1

1 Process Data

Input.Switching

Signal Channel 1.2

Pressure

1-bit Uinteger 0 = False

1 = True

- Switching signal

status SSC 1.2

8 Summary status

(Condensed)

8-bit UInteger • 36 = Error

• 60 = Function

check

• 120 = Outside

specifications

• 128 = Good

• 129 =

Simulation

• 164 =

Maintenance

required

- Summary status as

per PI specification

16 Pressure Float32 - psi: 0 /

0.0001450326

bar: 0 / 0.00001

kPa: 0 / 0.001

MPa: 0 / 0.000001

Current pressure

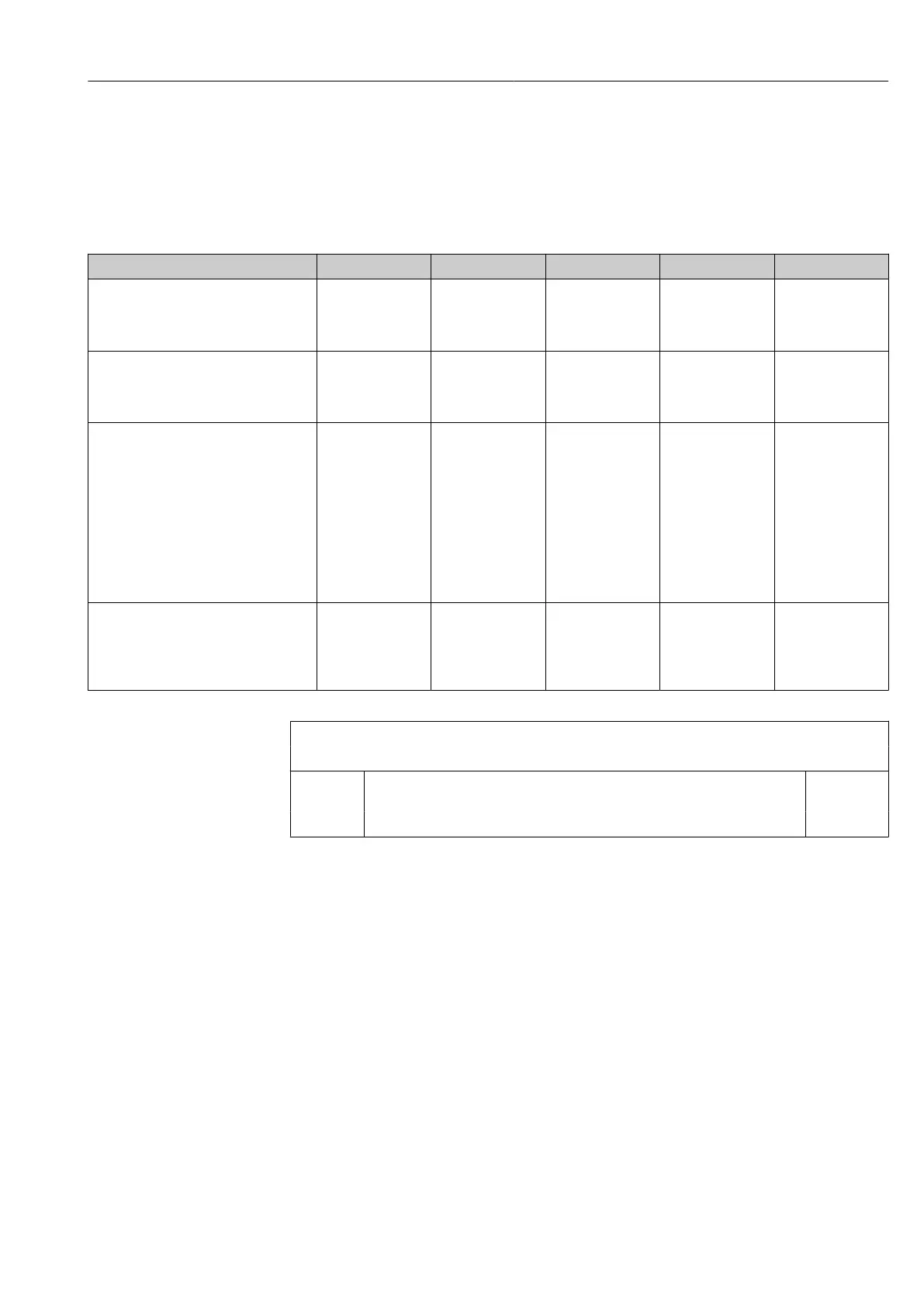

Process Value Pressure [Float32]

[47...16 bit]

Condensed

status

N/A SSC 1.1-1.2

[15...8 bit] [7...2 bit] [1.0 bit]

8.2 Reading out and writing device data (ISDU – Indexed

Service Data Unit)

Device data are always exchanged acyclically and at the request of the IO-Link master.

Using the device data, the following parameter values or device statuses can be read out:

Loading...

Loading...