Installation Cerabar M, Deltabar M, Deltapilot M / 4...20 mA HART

30 Endress+Hauser

3.5.8 Supplementary installation instructions

Seal

• Deltapilot M with a G 1 1/2 thread:

When screwing the device into the tank, the flat seal has to be positioned on the sealing surface

of the process connection. To avoid additional strain on the process isolating diaphragm, the

thread should never be sealed with hemp or similar materials.

• Deltapilot M with NPT threads:

– Wrap Teflon tape around the thread to seal it.

– Tighten the device at the hexagonal bolt only. Do not turn at the housing.

– Do not overtighten the thread when screwing. Max. torque: 20 to 30 Nm (14.75 to 22.13 lbf ft)

Sealing the probe housing

• Moisture must not penetrate the housing when mounting the device, establishing the electrical

connection and during operation.

• Always firmly tighten the housing cover and the cable entries.

3.6 Mounting of the profile seal for universal process

mounting adapter

For details on mounting, see KA00096F/00/A3.

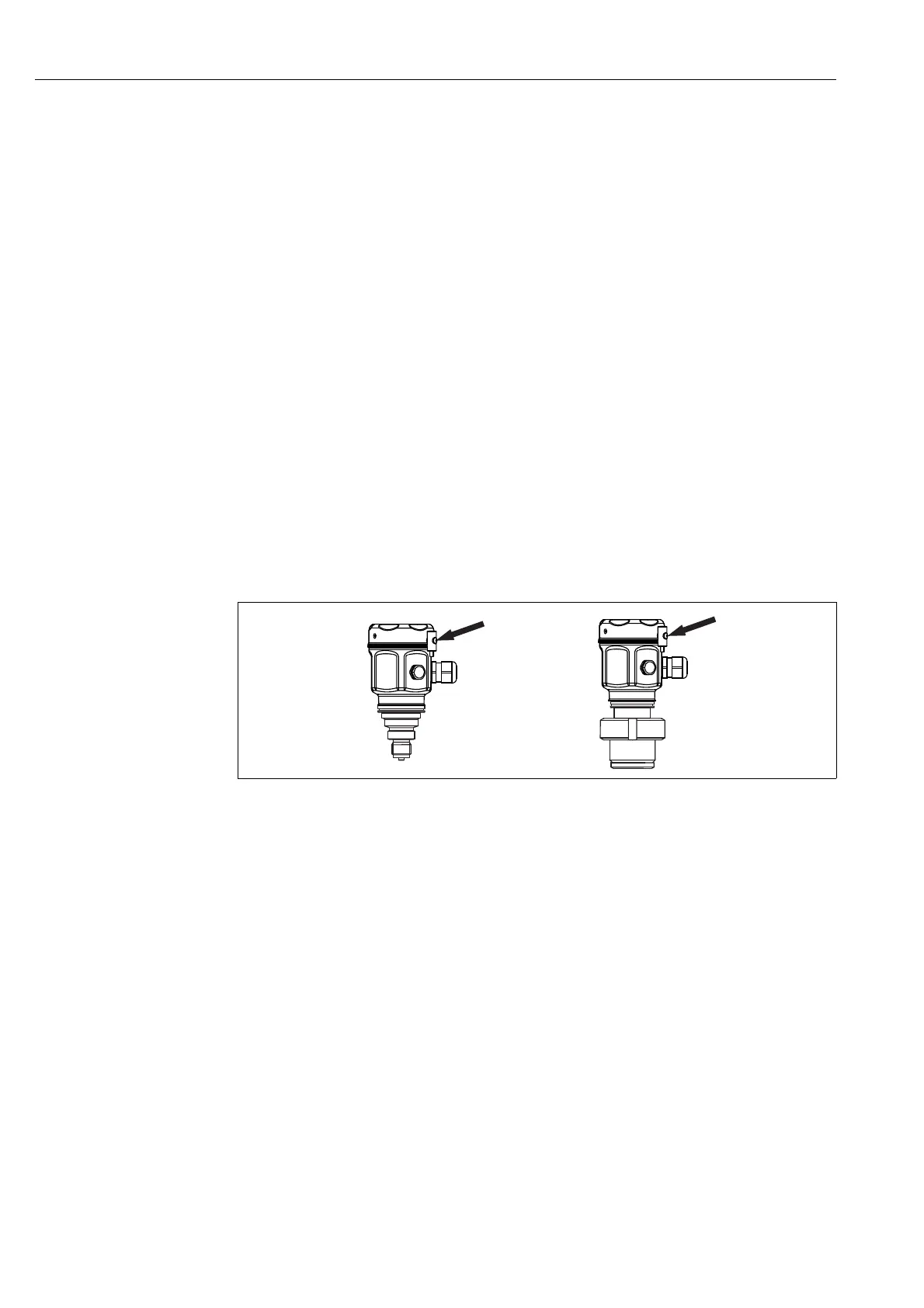

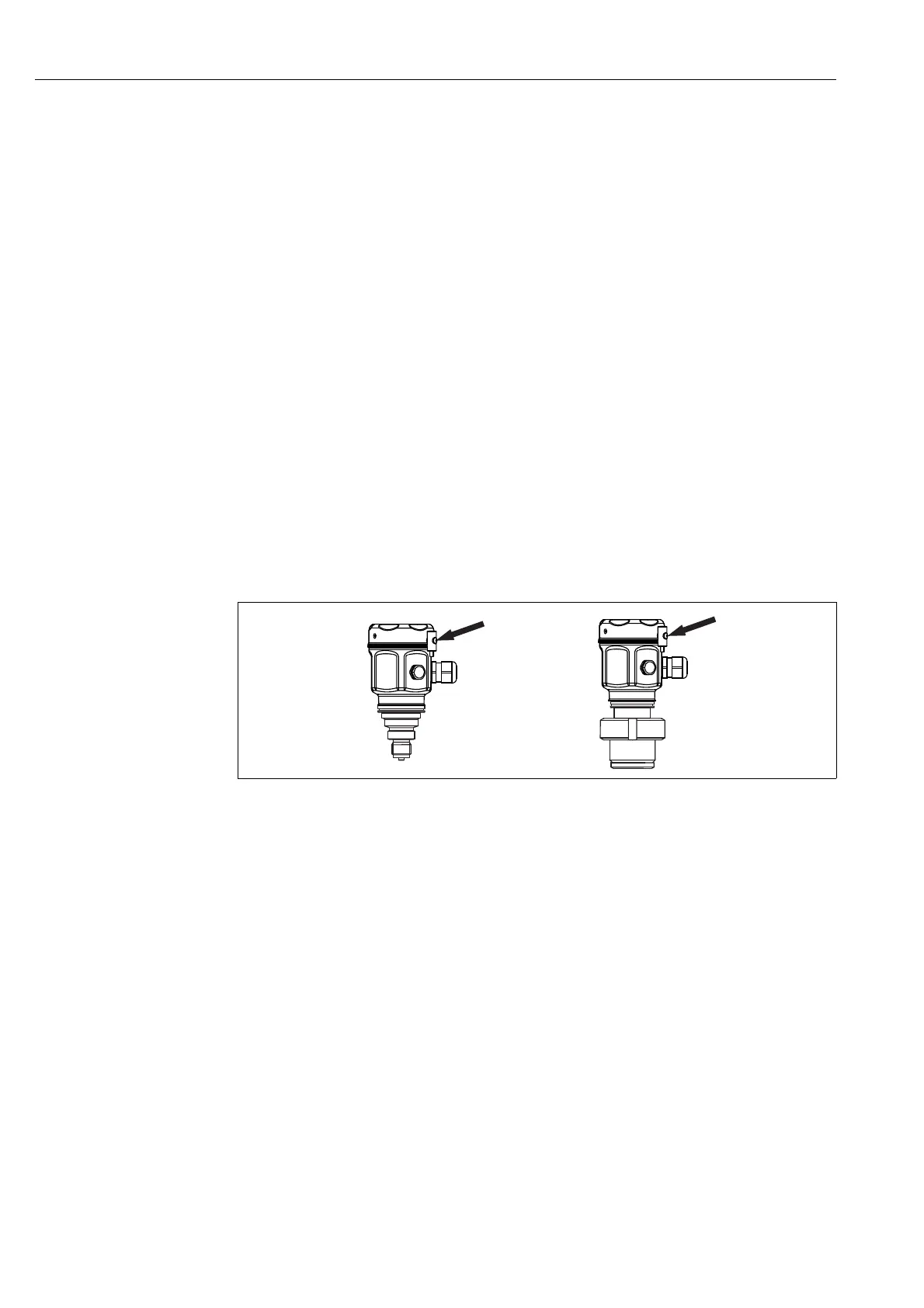

3.7 Closing the cover on the stainless steel housing

P01-XMx5xxxx-17-xx-xx-xx-001

Fig. 19: Closing the cover

The cover for the electronics compartment is tightened by hand at the housing until the stop. The

screw serves as DustEx protection (only available for devices with DustEx approval).

3.8 Post-installation check

After installing the device, carry out the following checks:

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

• Are all locking screws and vent valves (Deltabar M only) firmly tightened?

Loading...

Loading...