Cerabar M, Deltabar M, Deltapilot M / 4...20 mA HART Commissioning

Endress+Hauser 73

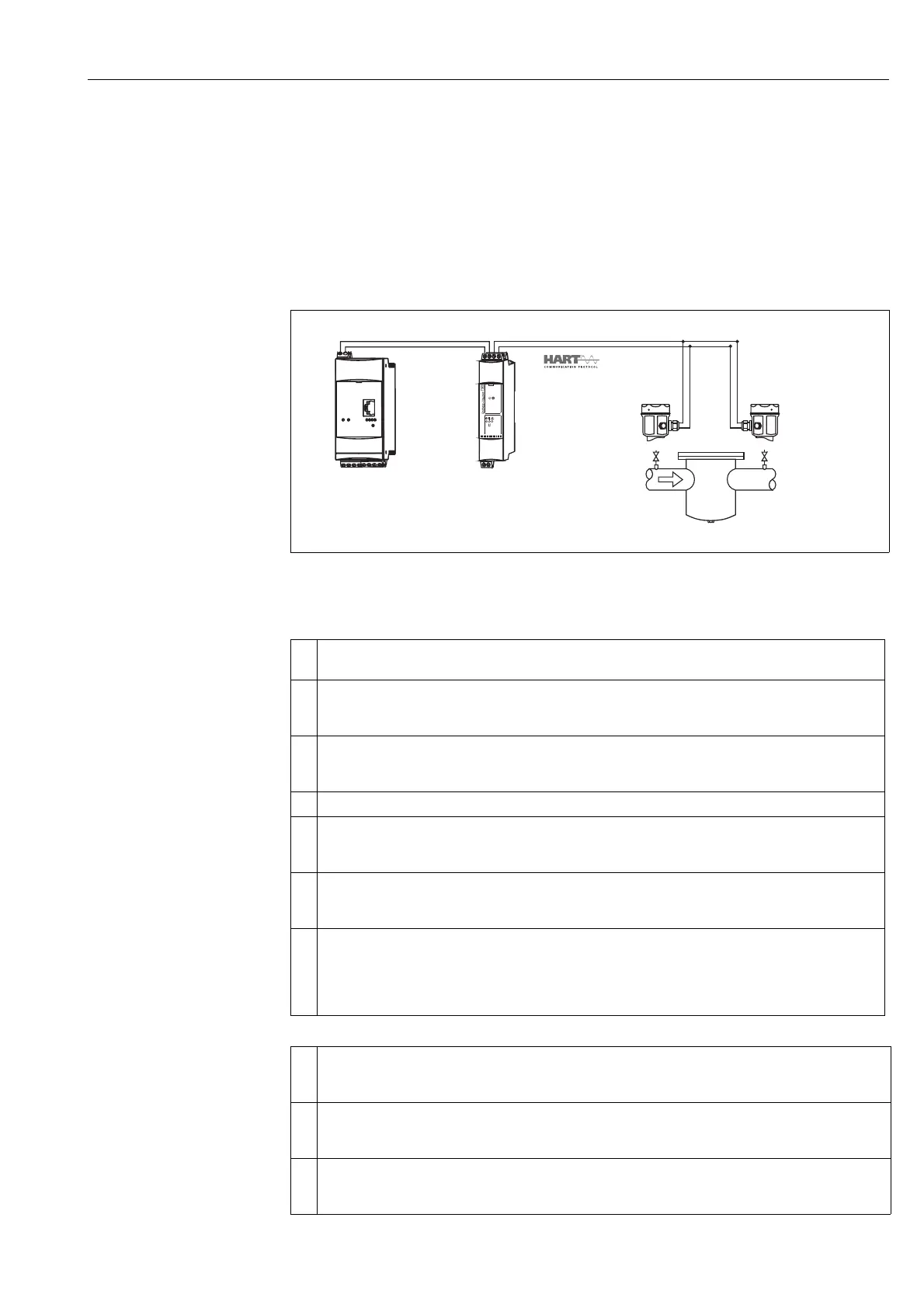

6.8 Electrical differential pressure measurement with

gauge pressure sensors (Cerabar M or Deltapilot M)

Example:

In the example given, two Cerabar M or Deltapilot M devices (each with a gauge pressure sensor)

are interconnected. The pressure difference can thus be measured using two independent Cerabar

M or Deltapilot M devices.

!

Note!

For a description of the parameters mentioned Chap. 10.2 "Description of parameters".

P01-XMX5Xxx-14-xx-xx-xx-001

1 Shut-off valves

2 e.g. filter

Fieldgate

FXA520

FXN 520

FXN 520

Multidrop-Connector

FXN520

Cerabar M/

Deltapilot M

➀

➁

➀

➁

Cerabar M/

Deltapilot M

Description

Adjustment of the Cerabar M/Deltapilot M on the high pressure side

1 Select the "Pressure" measuring mode via the "Measuring mode" parameter.

Menu path: Setup Measuring mode

2 Select a pressure unit via the "Press eng. unit" parameter, here "mbar" for example.

Menu path: Setup Press. eng. unit

3 The Cerabar M/Deltapilot M is unpressurized, perform position adjustment, see ä 56.

4 Switch on burst mode via the "Burst mode" parameter

Menu path: Expert Communication HART Config.

5 Set the output current to "Fixed" 4.0 mA via the "Current mode" parameter.

Menu path: Expert Communication HART Config

6 Configure an address 0 via the "Bus address" parameter, e.g. bus address = 1

(HART 5.0 master: Range 0 to 15, where address = 0 calls up the "Signaling" setting; HART 6.0 master: range 0 to

63)

Menu path: Expert Communication HART Config.

Description

Adjustment of the Cerabar M/Deltapilot M on the low pressure side (the differential is generated in this

device)

1 Select the "Pressure" measuring mode via the "Measuring mode" parameter.

Menu path: Setup Measuring mode

2 Select a pressure unit via the "Press eng. unit" parameter, here "mbar" for example.

Menu path: Setup Press. eng. unit

Loading...

Loading...