SC-S30600 Series Revision B

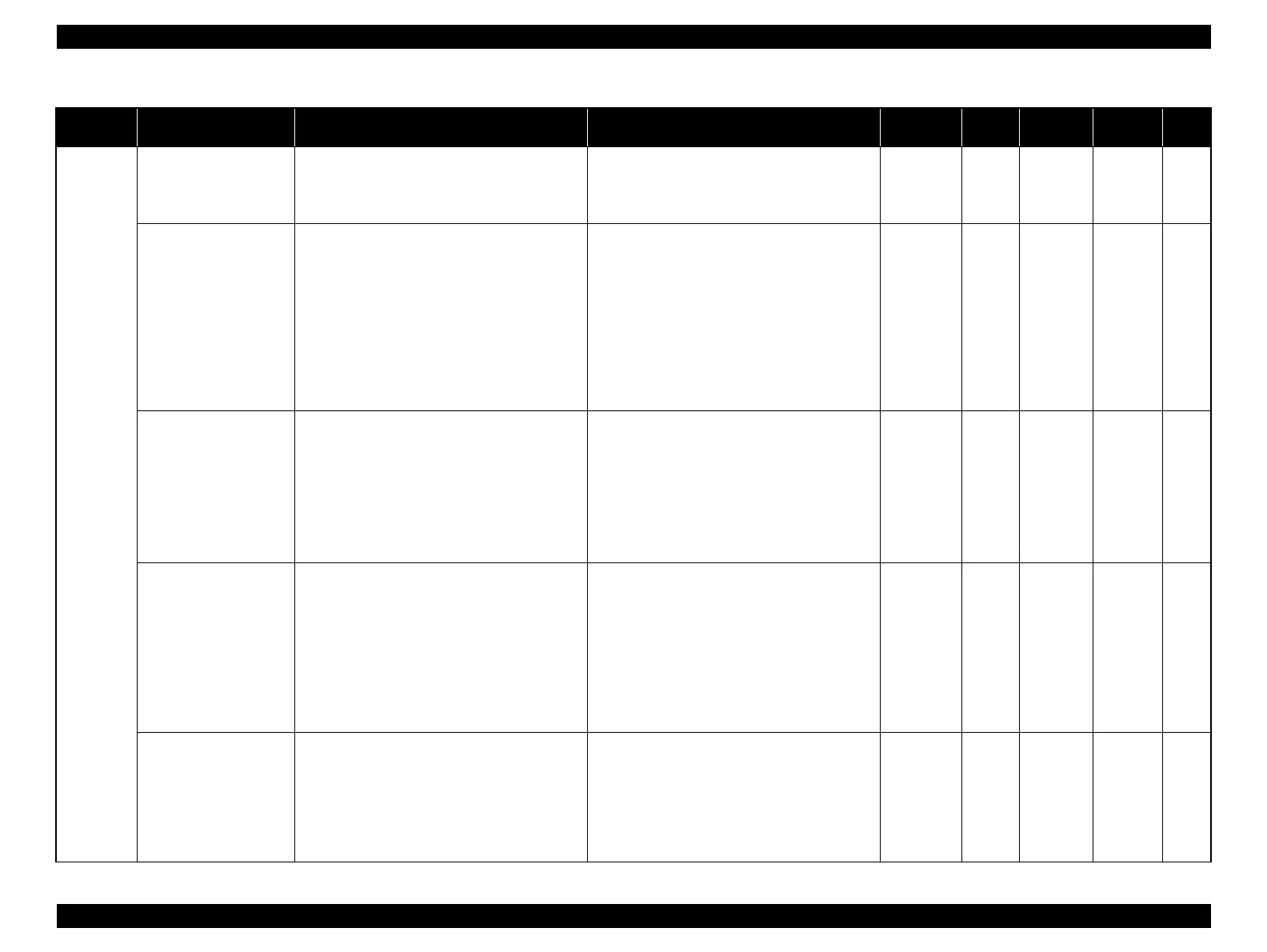

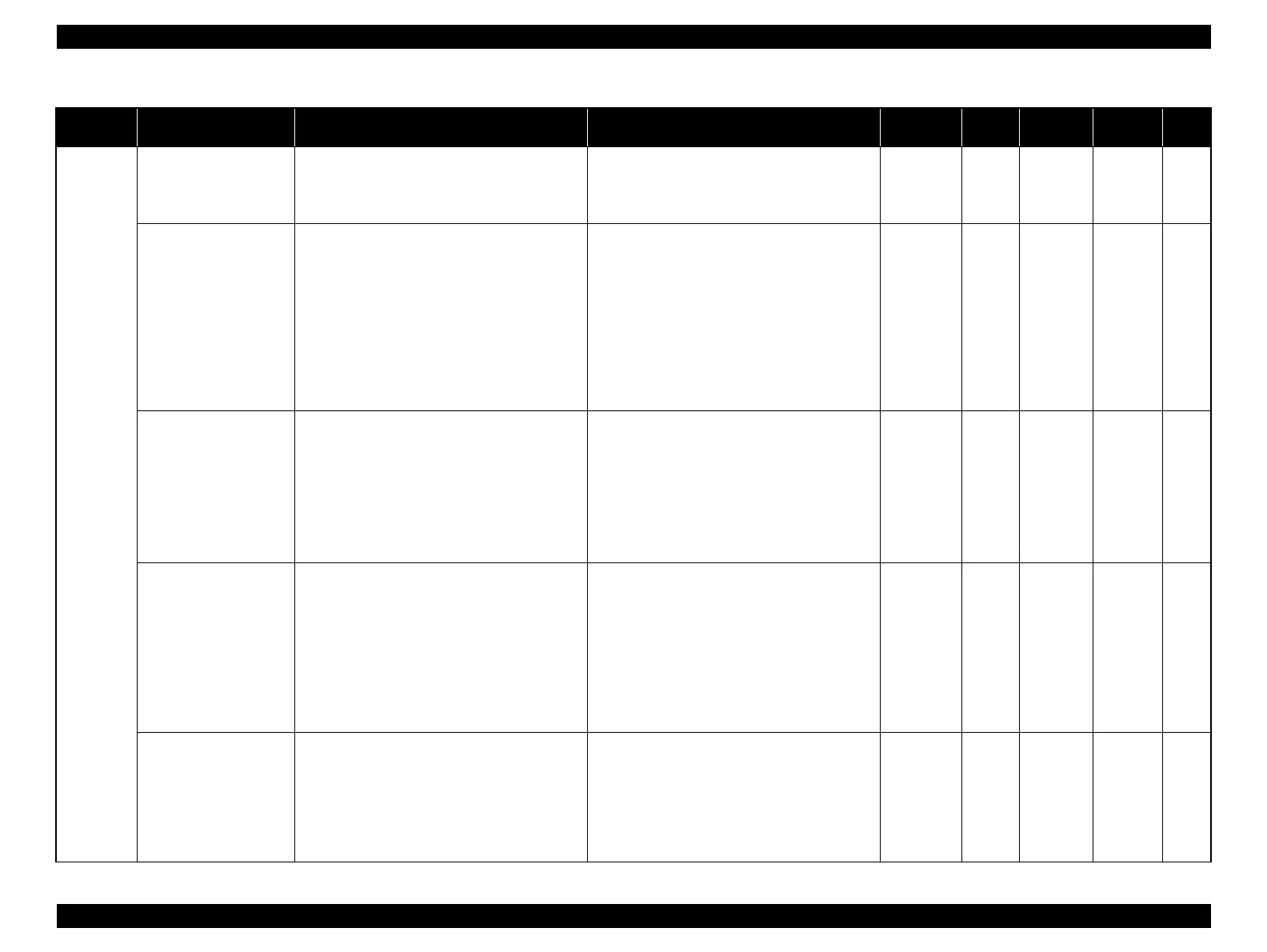

ADJUSTMENT Overview 212

Confidential

Head

related

Tube inner pressure

reduction

Reduce the pressure in the ink flow paths. Doing

this prevents ink leakage that can occur when

removing the Print Head or other ink related

parts/units.

---

Normal

mode

p.245

Head ID Input

Register the head rank ID to the printer using the

Service Program or check the currently registered

head rank ID. Head rank ID is information

needed to drive the Print Head with proper

voltages so that proper amount of ink droplets are

fired. The ID is assigned to each head and listed

on the label on the head.

If the new ID is not registered after replacing the

head, the head ID of the older head is used and

the proper drive voltage cannot be set. The

following symptoms may occur.

Since the amount of ink droplets is not proper,

the color and density abnormalities are found

on prints.

Since the amount of ink droplets turns to be

unstable, dot missing or misaligned dots occur

while printing or flushing.

Normal

mode

p.246

Nozzle Check

Print the pattern on which the nozzle discharging

condition can be checked from the Service

Program.

When the Nozzle Check is not executed and the

nozzle is clogging, the following symptoms may

occur.

The adjustment pattern is not printed properly

and it causes a trouble for the automatic and

visual check/adjustment.

The automatic adjustments may fail or end

with an error.

Normal

mode

p.248

Cleaning

Specify the power and the color from the Service

Program and execute the head cleaning.

When the cleaning is not executed, the following

symptoms may occur.

Nozzle clogging is not solved and the printing

cannot be executed properly.

Ink droplets are not fired and nothing is

printed after the Print Head is replaced to a

new one. (Executing Initial ink charge may

solve this problem but it takes time and

consumes lots of ink.)

Normal

mode

p.250

Head inclination auto

adjustment

(CR direction)

Correct inclination of the Print Head in the CR

direction. An adjustment pattern is printed and

the IM Sensor scans the pattern. Based on the

scanned result, a number of steps to move the

cam for the adjustment is displayed. Turn the

cam the number of steps to correct the head

inclination.

If this adjustment is not made, print quality

problems such as misaligned lines, grainy image,

banding, or color unevenness may occur in the

scale of Print Head surface area.

Normal

mode

p.251

Table 4-2. Adjustment Items

Class Adjustment Items Overview Symptoms that the Adjustment is Needed Printer Mode

Service

Program

Jig Media Page

Loading...

Loading...