Maintenance 8. Arm #4

G6 Rev.21 161

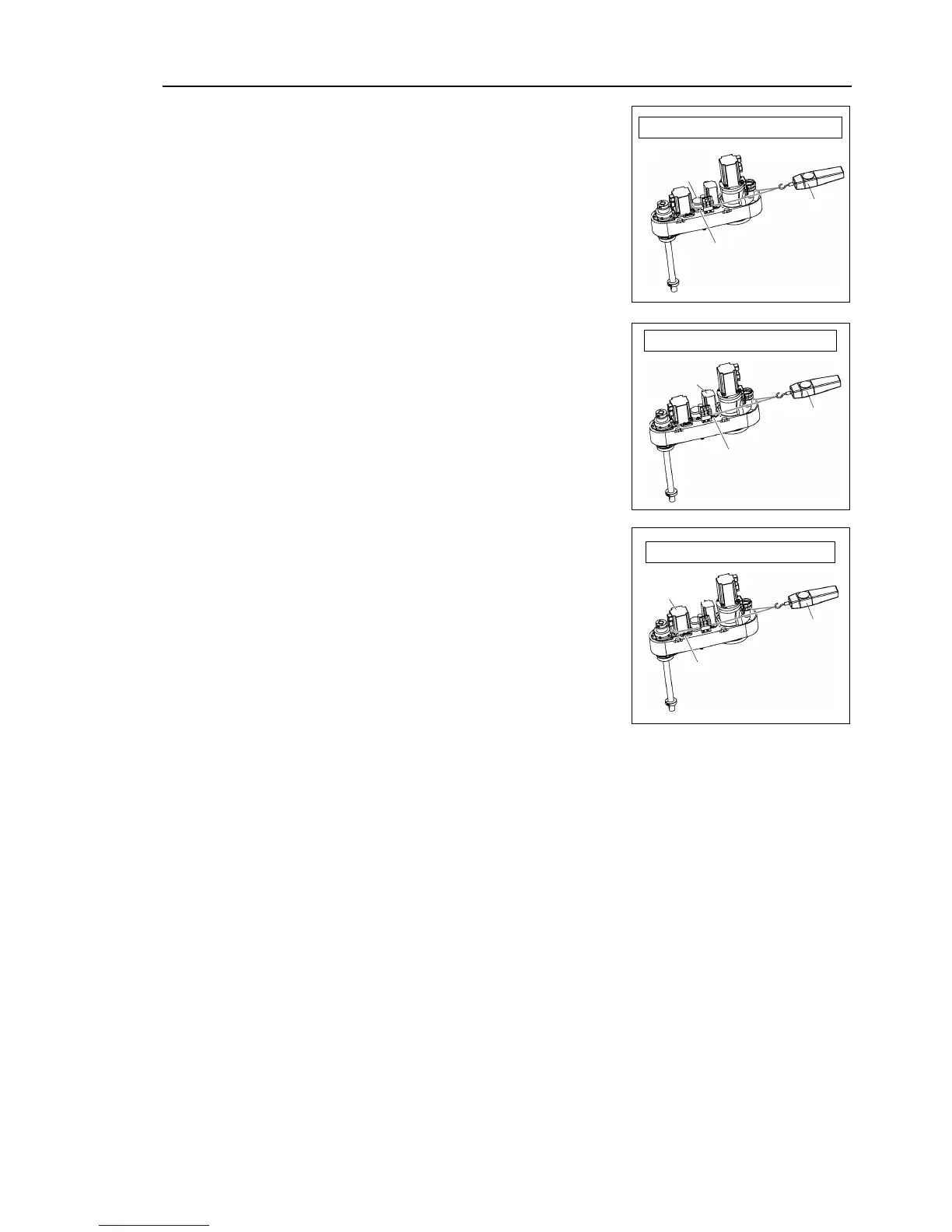

Apply the proper tension to the

4 intermediate shaft unit.

To do so, pass a suitable cord or string

4 intermediate shaft unit near its

Then, pull the cord using a

force gauge or similar tool to apply the

tension shown in the figure on

Joint #4

Intermediate

shaft unit

U2 belt tension = 130 N

(13.2

kgf)

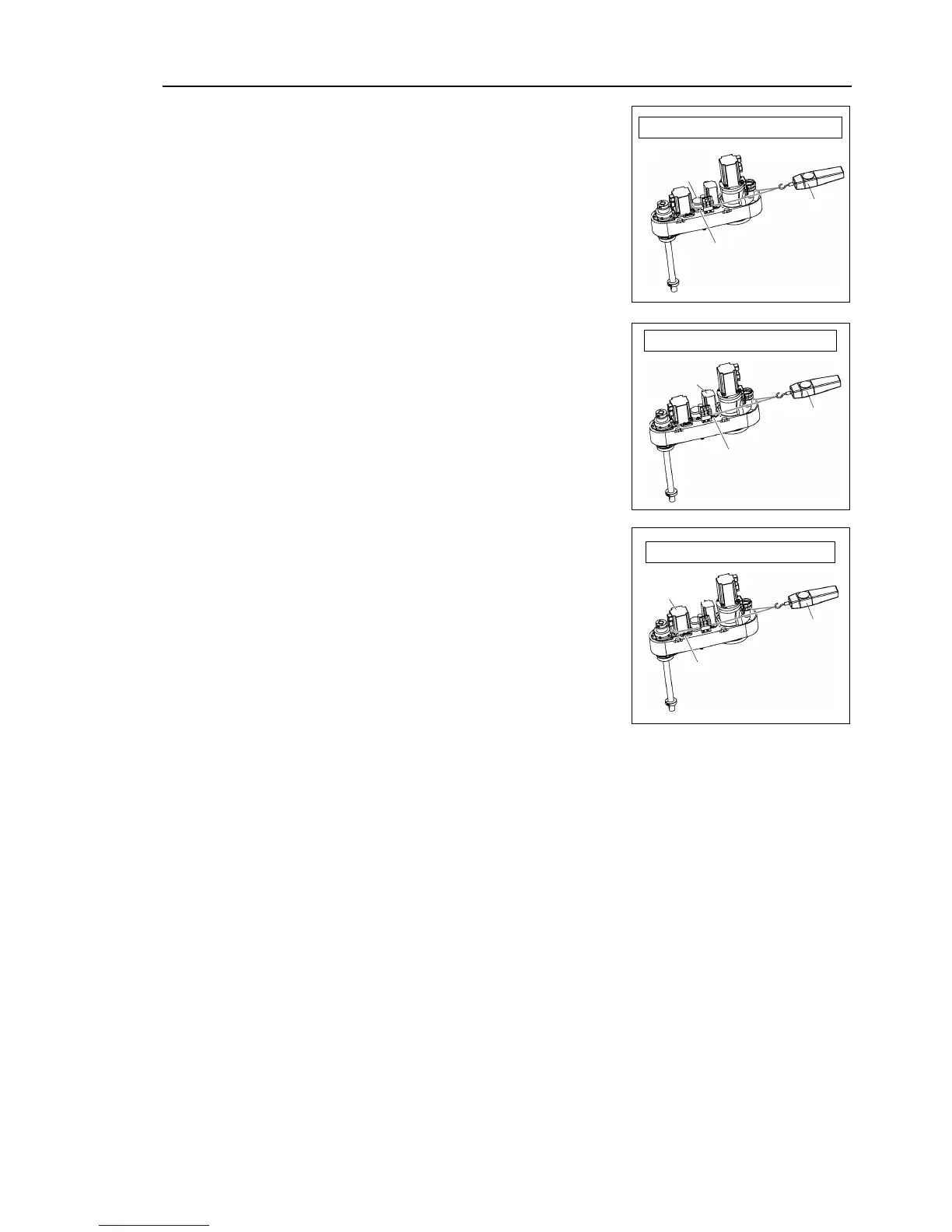

Apply the proper tension to the

To do so, pass a suitable cord or string

4 motor unit near its mounting plate.

Then, pull the cord using

similar tool to apply the

U1 belt tension = 70 N (7.1 kgf)

Apply the proper tension to the

To do so, pass a suitable cord or string

3 motor unit near its mounting plate.

Then, pull the cord using

similar tool to apply the

Make sure that the brake cables do not

Z belt tension = 80 N (8.1 kgf)

.

Connectors X231, X31, X32, X63.

-bundle the cables in their original positions with a wire tie removed in step (5).

Do not allow unnecessary strain on the cables.

top cover and arm bottom cover.

For details, refer to Maintenance: 3. Covers.

calibration of Joints #3 and #4.

For details, refer to Maintenance: 13. Calibration.

Loading...

Loading...