EPSON Stylus CX4100/CX4200/CX4700/CX4800/DX4200/DX4800/DX4850 Revision A

OPERATING PRINCIPLES Printer Mechanism 63

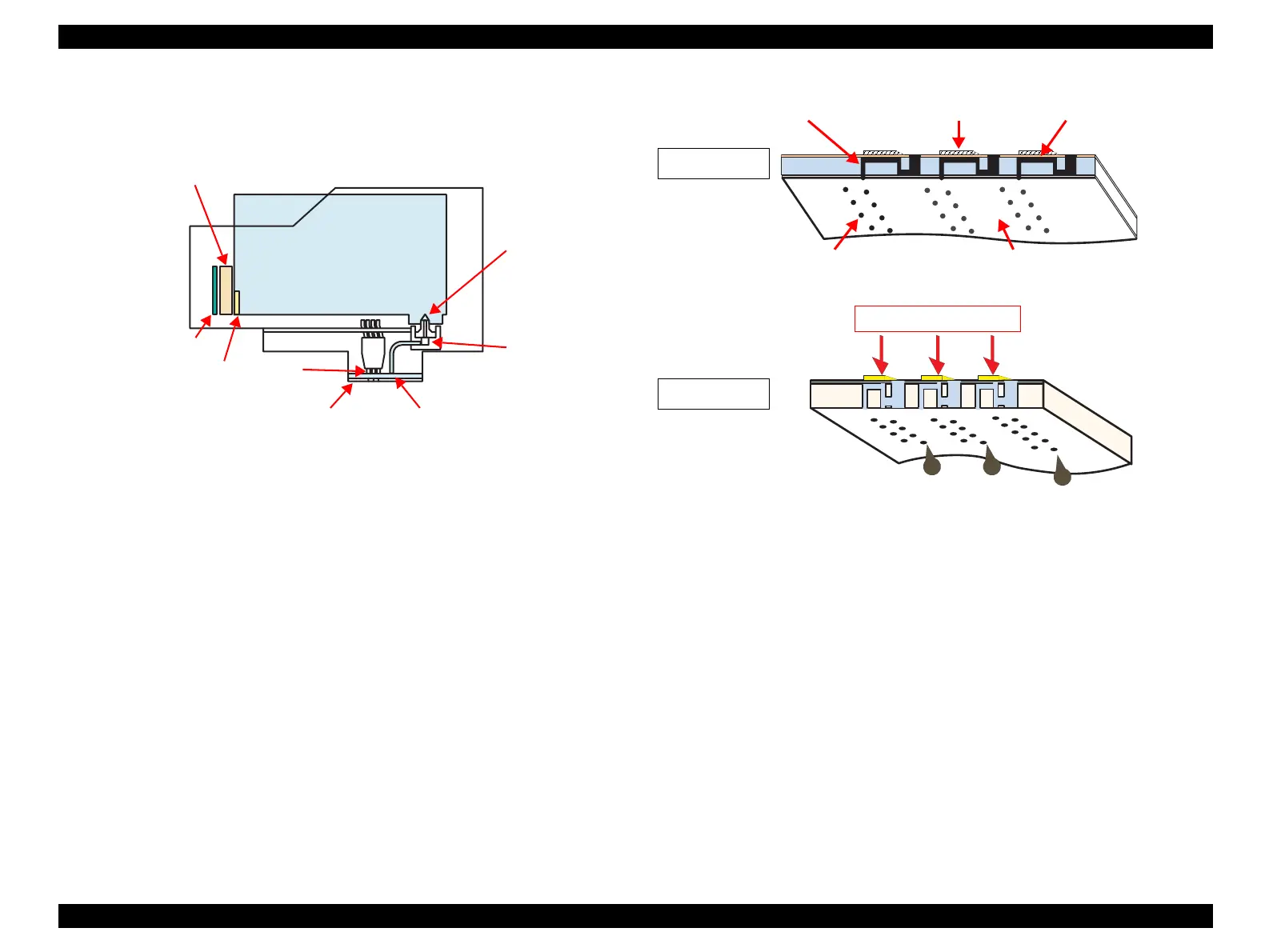

Ink Cavity

The ink absorbed from the Ink Cartridge goes through the filter and then is stored

temporarily in this tank called “ink cavity” until PZT is driven.

Figure 2-3. Printhead sectional drawing

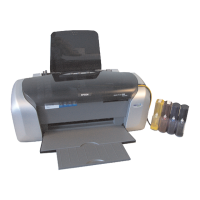

2.2.2.1 Printing Process

This section explains the process which the Printheads of On-Demand inkjet printers

eject ink from each nozzle.

1. Normal state:

When the printing signal is not output from the Main Board (C610 Main), or the

PZT drive voltage is not applied, the PZT does not change the shape. Therefore,

the PZT does not push the ink cavity. The ink pressure inside the ink cavity is kept

normal. (refer to Figure 2-4 (p.63): Normal state)

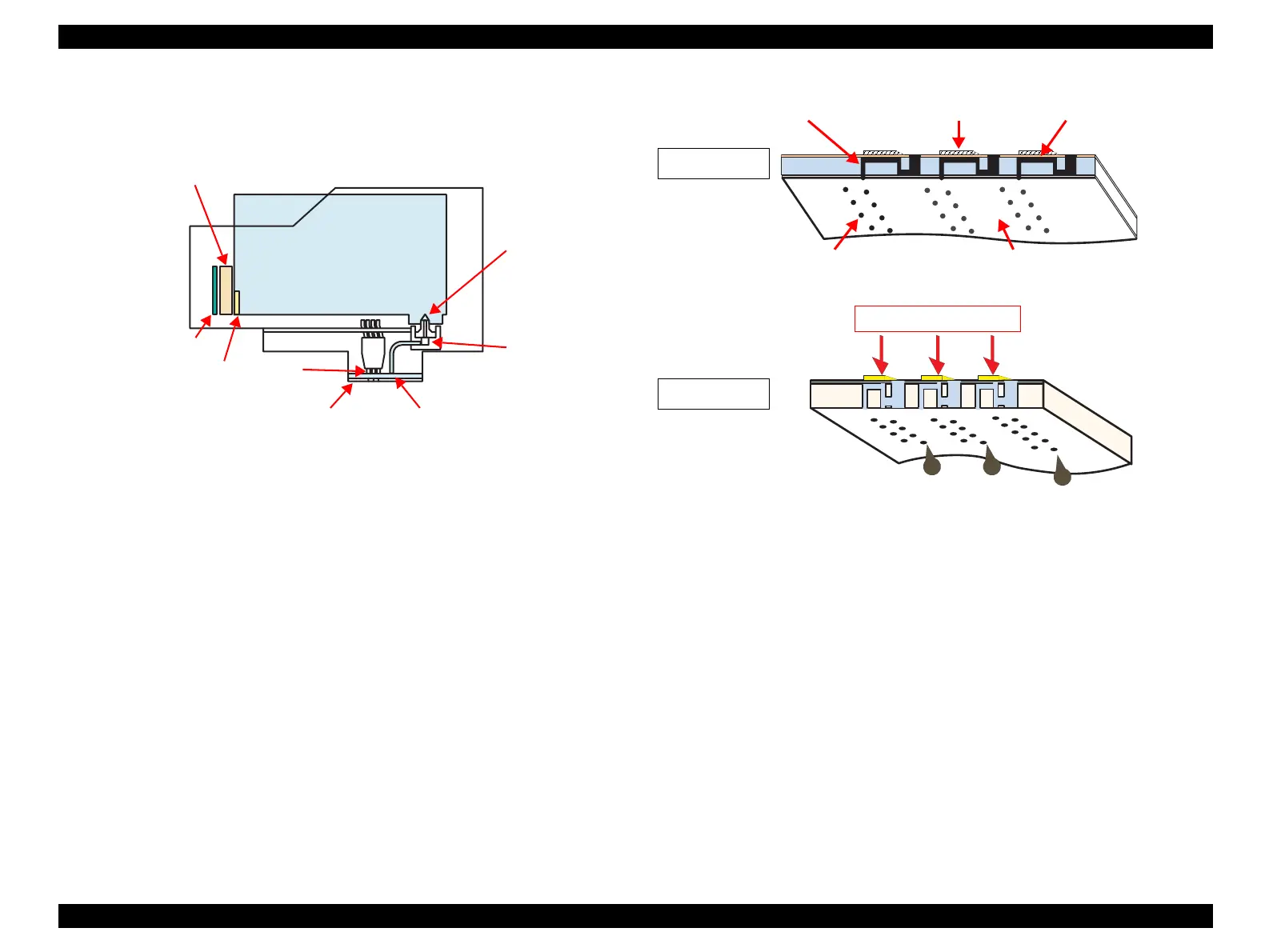

2. Ejecting state:

When the print signal is output from Main Board (C610 Main), the nozzle selector

IC located on the Print Head latches the data once by 1-byte unit. Based on the

drive waveform (common voltage) generated on the Main Board, the PZT selected

by the nozzle selector IC pushes the top of the ink cavity. By this operation, the ink

stored in the ink cavity is ejected from nozzles. (refer to Figure 2-4 (p.63):

Ejecting state)

Figure 2-4. Print Head printing process

2.2.2.2 Printing Method

The dot printing systems of Stylus CX4100/CX4200/CX4700/CX4800/DX4200/

DX4800/DX4850 are variable dot printing systems.

Variable dot printing

This printing mode is developed to improve the print quality on exclusive paper.

This mode is basically the same as variable dot printing mode used on other

products; micro dot, middle dot and large dot compose this mode. The printing dot

size varies according to the print data and this mode enables to output even sharper

image on exclusive paper.

Nozzle selector board

Needle

Ink cartridge

Cavity

PZT

Nozzle plate

CSIC Memory chip

Electric poles for CSIC

*Head ID for the Print Head is

stored to the EEPROM.

Filter

Ink path PZT Ink cavity

Nozzle Nozzle plate

PZT drive voltage

Normal state

Ejecting state

Loading...

Loading...