Maintenance 14. Joint #6

216 VT Rev.1

Apply proper tension to the motor unit and

Joint #5 timing belt tension: 23 - 36N

Belt tension meter setting values

Weight: 2.5g/mm width×m span

Width: 6.0mm

Span: 184mm

Hexagon socket head cap bolts: 3-M4×20 (with slotted hole washer)

Tightening torque: 4.0 ± 0.2 N·m

Jumping (position gap) may occur if the value is below the lower limit.

Vibration (abnormal noise) or reduction in life of the parts may occur if the value

exceeds the upper

When you replace with a new

belt, belt extends and the belt tension may decrease in

the initial stage.

Make sure to operate the robot two to three days and check the belt

tension again

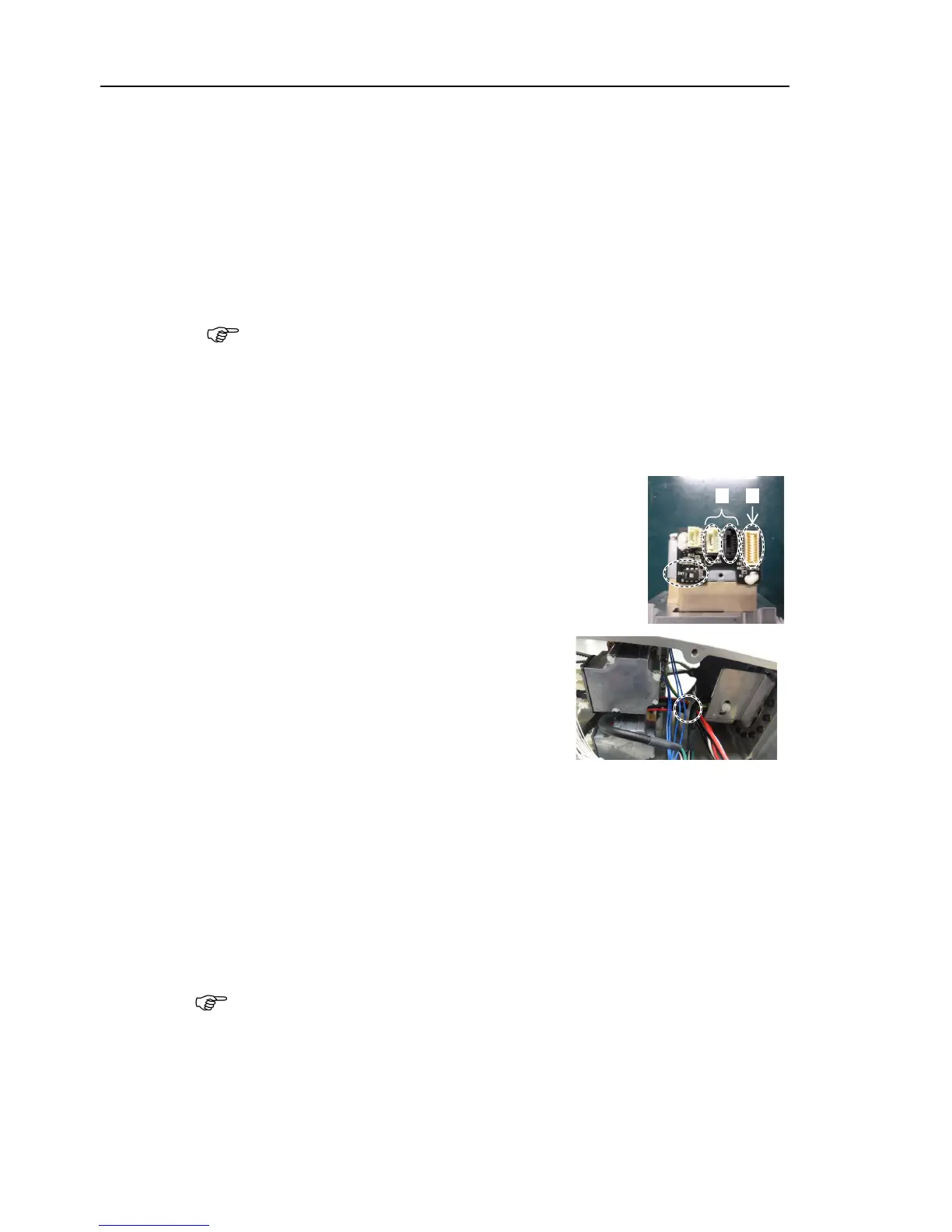

the following connectors of the motor.

A: Signal cable connectors (for motor × 2)

B: Signal cable connector (for AMP board)

the signal cable connector (for motor) is the

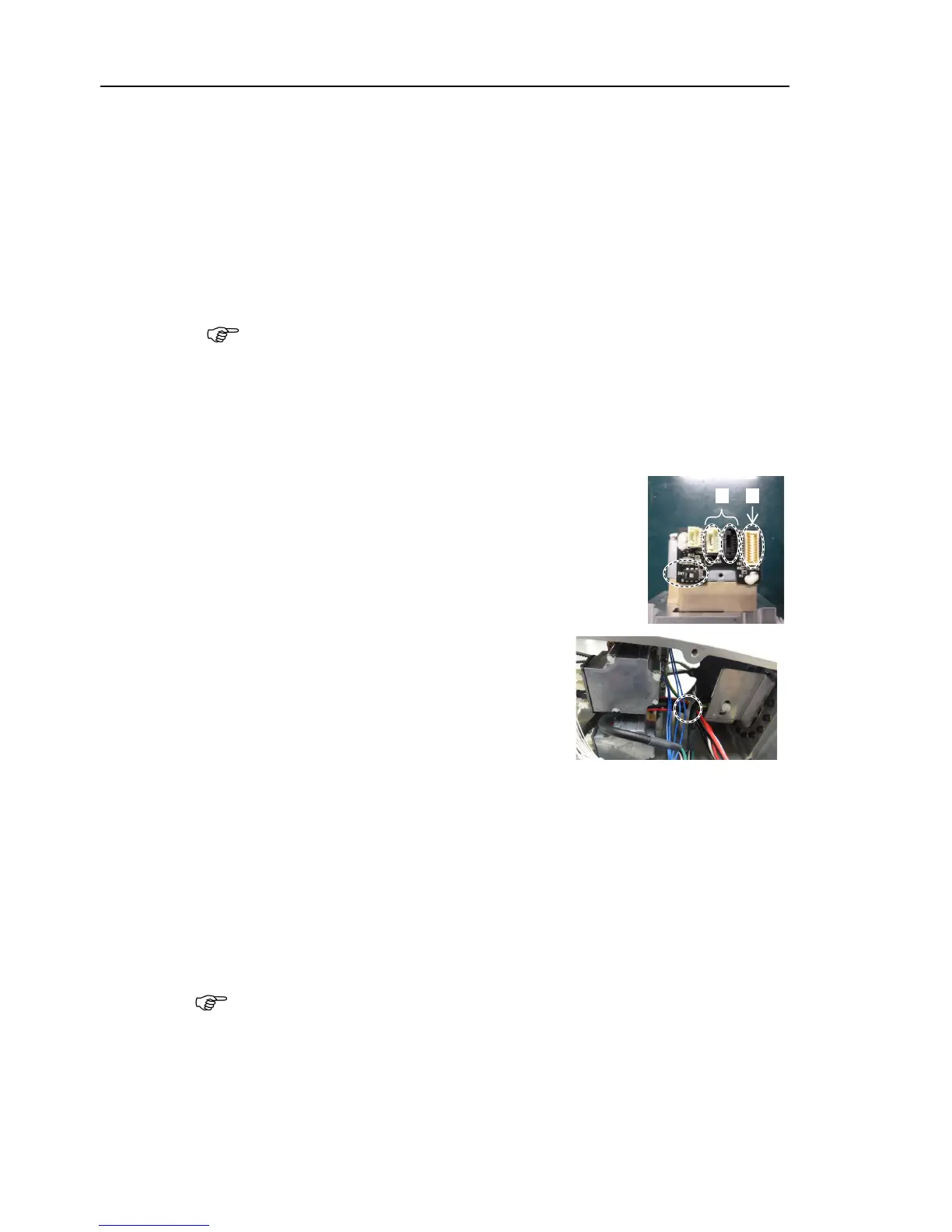

Bind the following cables and the ground wire with

the

wire tie.

Wire tie: AB100

Motor cable (Joint #5)

Signal cable (Joint #5)

Motor cable (Joint #6)

Ground wire

the following covers.

Arm #4 Cover 1

Arm #4 Cover 2

Reference: Maintenance 7. Covers

the Manipulator.

Reference: Setup & Operation 6.5 LED

When starting the manipulator for the first time after replacing the motor unit, the

motor unit firmware is automatically updated.

DO NOT turn OFF the manipulator

Joint #6.

Reference: Maintenance 19. Calibration

Loading...

Loading...