Spc. No.

ECSP07011 2/4

A cable port is provided to allow users to run wires and other lines into the chamber. This 2” (50mm) diameter port comes with

one flexible silicone port plug (impervious to water), which can be used to seal the port. The exterior comes equipped with a screw

on cap for sealing the port when it is not in use. Additional ports can be added as an option on left, right, or top. ESPEC uses a

non-metallic sleeve as a thermal break between the interior and exterior with all cable ports.

All models include heavy-duty vibration isolation feet. Primary service panels are lift-off style for convenient access.

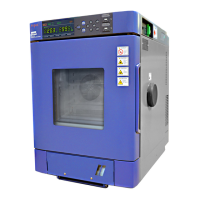

Items found on the front facing electrical enclosure: Controller/programmer, chamber run switch, chamber fault light and fault

reset switch. A separate interface panel, on the left side, allows access to external relays, option recorder connection,

communication connections and the overheat protector.

3. Refrigeration systems:

Ultimate low

temperature (as shown

on specification)

Refrigeration type Refrigerant used Number of

compressors

-20 °C Single Stage R-404A 1

-70 °C Cascade R-404A and R-508B 2

x The refrigeration system is installed below and behind the chamber to provide for more ergonomic product loading

heights when placed on a 30” high bench. The refrigeration system is modular to allow for high quality construction

methods and ease of service.

x Refrigeration system is hermetically sealed for low potential for leak and high reliability.

x All models use air-cooled condenser for unit placement flexibility. The top exhaust system for the condenser allows the

unit to be placed directly against a wall, minimizing the required footprint.

x

MSDS documents on the refrigerants can be found by following these links:

R-404A

http://msds.dupont.com/msds/pdfs/EN/PEN_09004a2f80006eca.pdf

R-508B

http://msds.dupont.com/msds/pdfs/EN/PEN_09004a2f80007a09.pdf

.

4. Operational features:

Humidity controlled models (BTL or BTX) will have a humidity generator:

Model Size Humidity generation method

BTL/X-4 External steam generator, accessible from the machine room. Steam

generator is housed in a cylindrical enclosure, to allow for easier cleaning.

Water level control is located in the rear of the chamber.

Recirculating airflow is generated by one externally-mounted blower motor. The motor has a direct shaft into the chamber’s

plenum with a fan blade attached. The airflow in the specification (paragraph 1.5) is measured, not calculated. The number and

type of blowers:

Model(s) Number of blowers Blower motor

BT-1 1 x 4” 30 Watts

BT-4 1 X 5” 30 Watts

The temperature sensor is a type-T thermocouple.

The humidity sensor is a type-T thermocouple with a wet wick. The humidity is calculated based on standard psychometric

formulas. This allows for high accuracy readings at high humidity conditions without potential saturation of the sensor.

Loading...

Loading...