3. Product description

28 Festo.P.BE-CMMS-ST-G2-HW-EN 1008NH

The following signals can be evaluated:

• A/B tracking signals

• CLK/DIR – pulse/direction

• CW/CCW pulse

Input: Processing of pulse-direction signals 24 V DC [X1]

• CLK/DIR – pulse/direction

• CW/CCW pulse

24 V DC pulse-direction signals are carried out via X1 DIN2 and DIN3.

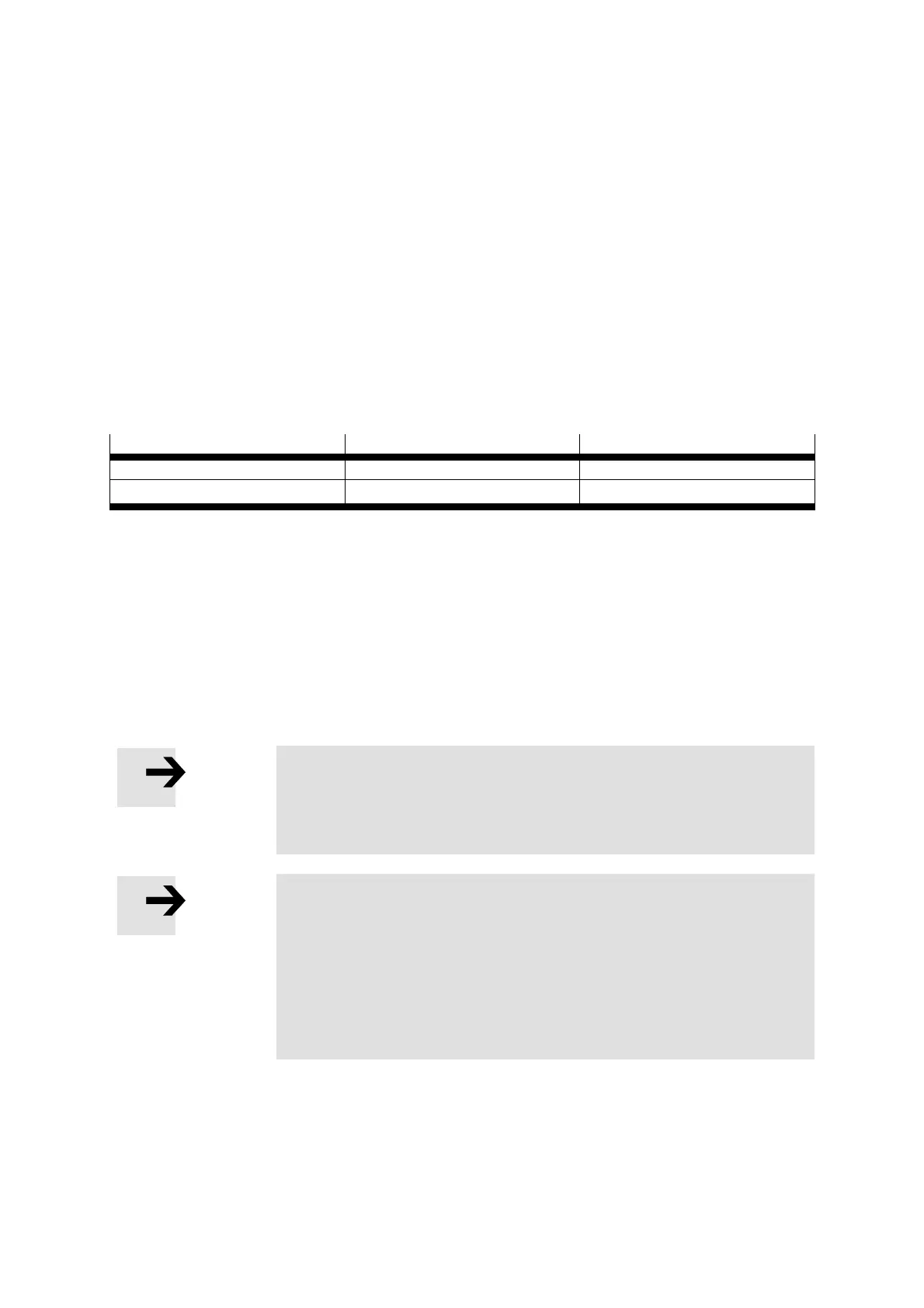

Cycle rate pulse-direction signals

Voltage Input Cycle rate

5 V [X10] 150 kHz

24 V [X1]

up to 20 kHz

Table 3.3 Maximum input frequency

Activation of synchronisation

Synchronisation can be set in various ways.

• With the FCT parameterisation software, through selection of the control interface

“Synchronisation” on the “Application data” page in the “Operating modes selection”

tab

• Via [X1] (digital I/O interface) through selection of mode 3

Note

With setting of synchronisation via FCT, the controller only reacts

via the synchronisation interface. All other functions of the

positioning operating mode are no longer available.

Note

After the change of configuration via FCT, the changed

configurations must be loaded into the motor controller using the

“Download” buttons and saved permanently with the “Save”

button.

With a “Reset” (or switching off and back on) of the motor

controller, the new configuration is activated.

To ensure flexibility of the controller, synchronisation should be switched on over the I/O

interface.

Loading...

Loading...