3. Product description

Festo.P.BE-CMMS-ST-G2-HW-EN 1008NH 71

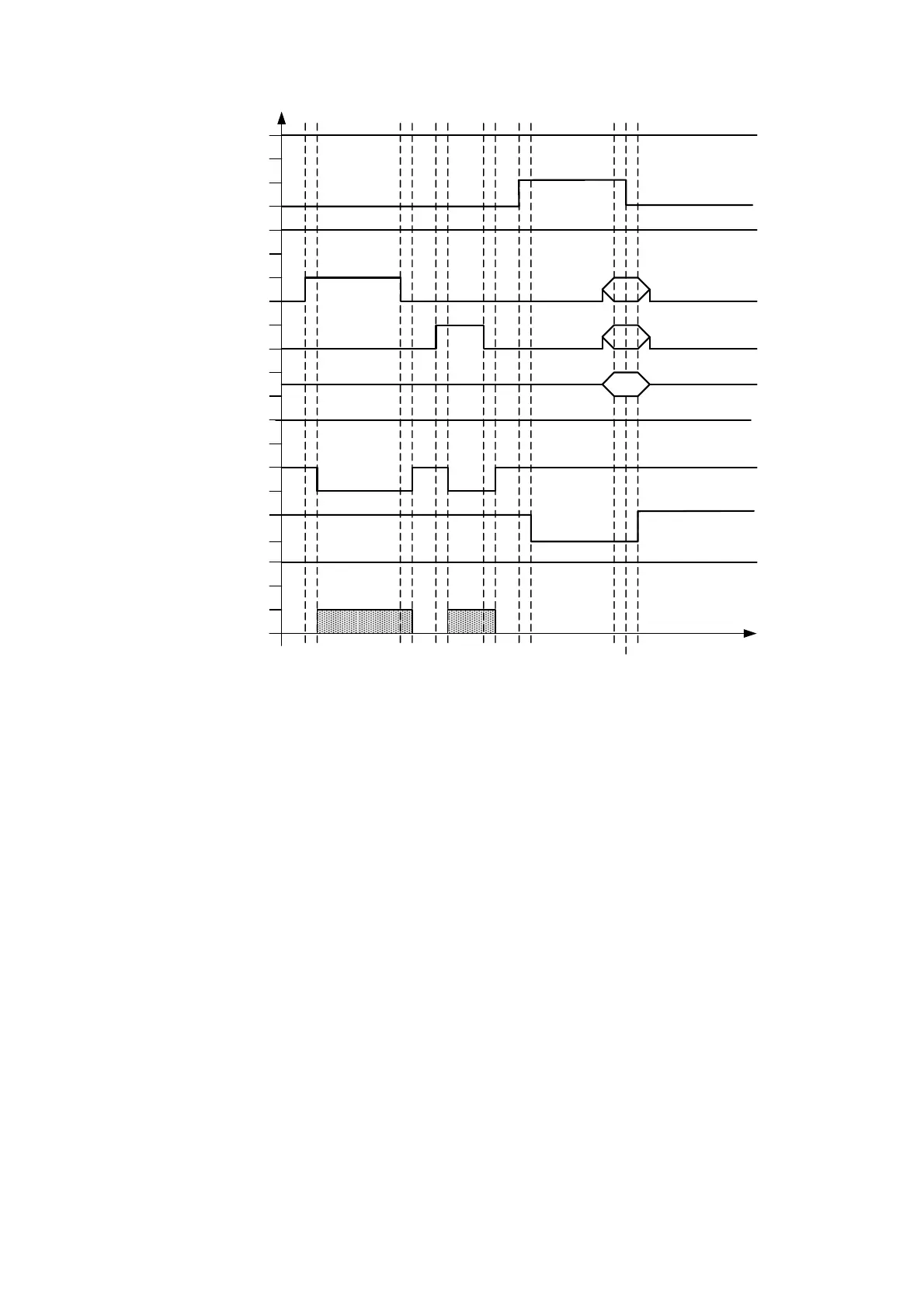

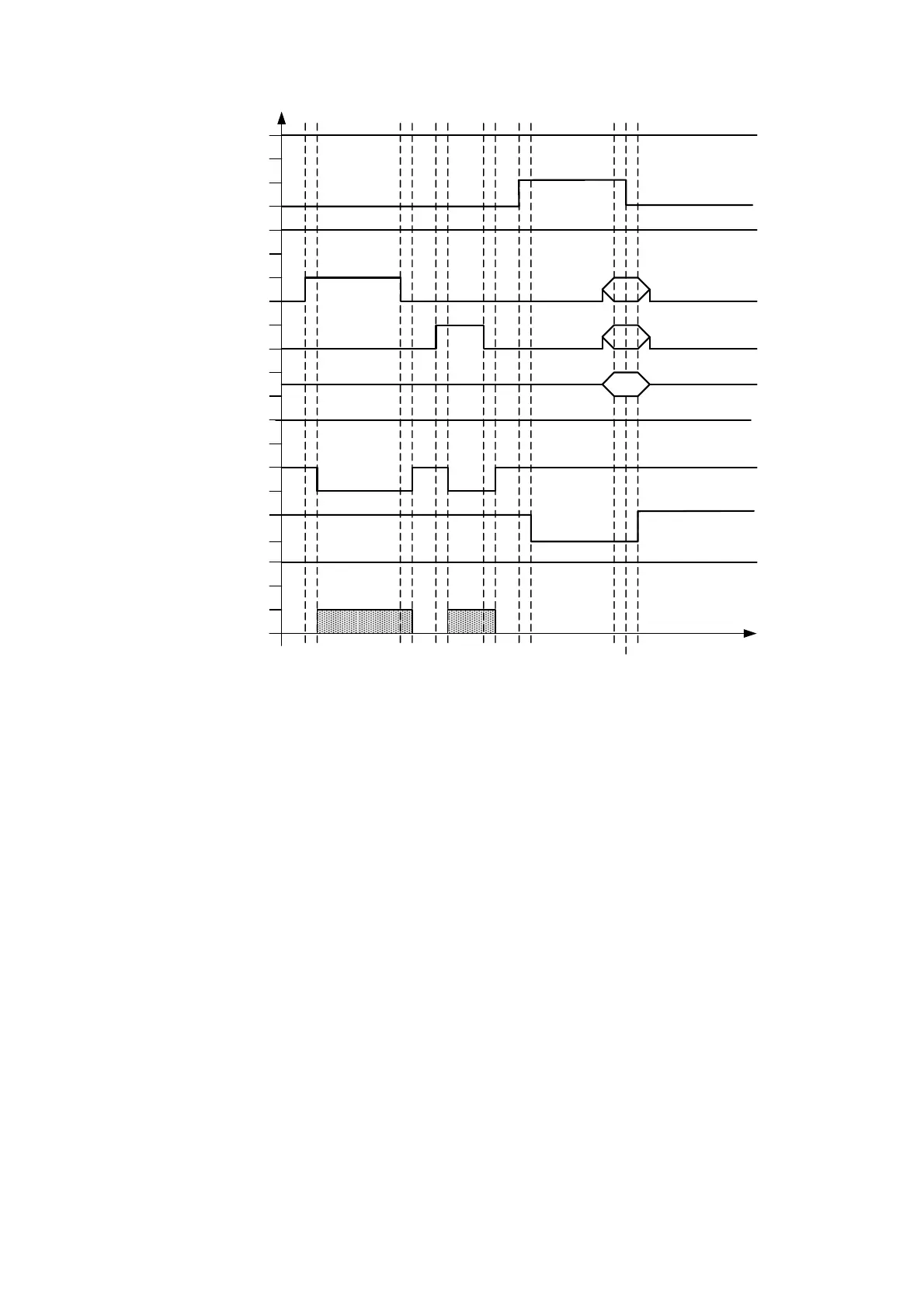

ENABLE

START / TEACH

STOP

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

–

1

0

+

(1)

(1)

DIN0 - DIN3

1

0

(1)

DOUT0 : READY

DOUT1: MC

DOUT2: ACK- TEACH

DOUT3 : ERROR

t1 t1tx tx t1 t1 t1

DIN11: Jog --

DIN10: Jog ++

Drive is moving

t1 = 1.6 ms

tx = x ms (dependent on brake ramps)

(1) Setting of the target position to be programmed

Fig.

3.12 Behaviour with teach input

3.5.15 Position record linking with positioning/torque control

switching

Positioning record linking allows multiple positioning jobs to be linked in a sequence.

These positions are travelled to one after another. The characteristics of positioning

record linking are:

• All 63 position records of the position record table can be set.

• Besides linear sequences, ring-shaped linkages are also allowed. (endless linkage)

• For each step, a free following position can be set.

• As step criterion, 2 digital inputs are available as NEXT 1 and NEXT 2.

• There are 7 possibilities to jump into position record linking with I/O control, that is,

7 different sequences are possible. Under FHPP, the entry is freely selectable and the

number limited only by the maximum number of position sets.

• The program lines are worked off every 1.6 ms. This ensures that a set output remains

set for at least 1.6 ms.

Loading...

Loading...