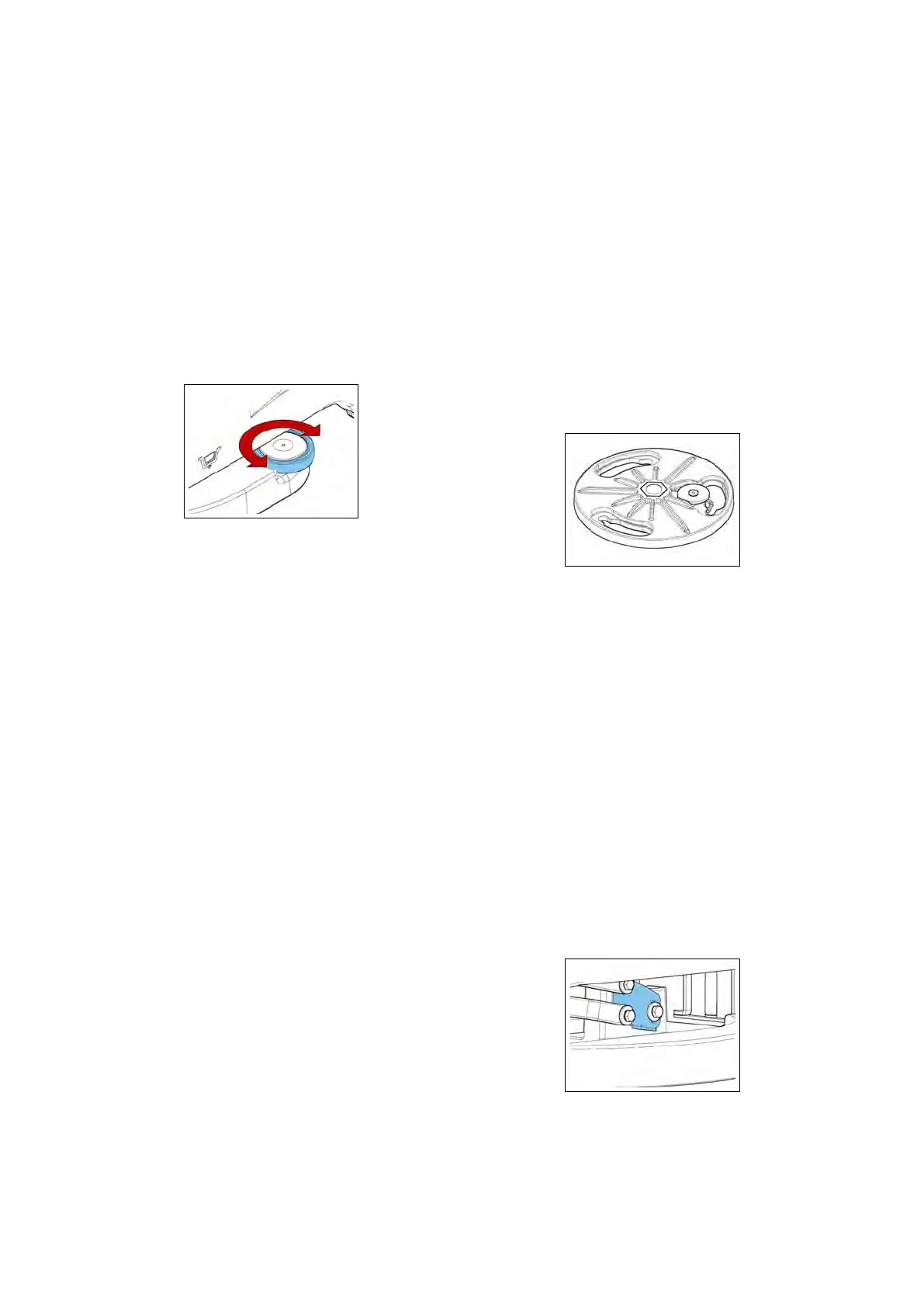

7.4.3 Bumping Wheel

Check (to perform every 150h)

The bumping wheel must be free to

rotate and its diameter must not be too

small due to wear. A bumping wheel in

poor condition can lead to cracking of

the brush base when working skimming

some obstacles (walls, shelving, etc).

If necessary, replace it.

7.4.3-111 Bumping Wheel

7.4.4 Brush Base

Check (to perform every 150h)

The brush base must be kept clean

and intact. A ruined brush base may

be dangerous to the machine and the

operator that uses it.

If necessary, replace it.

7.4.5 Lifting mechanism

Check (to perform every 150h)

The lifting mechanism should be clean

and lubricated. The lubrication of the

cables must be done with silicone spray,

it should not be used any grease or oil

to prevent that the dirt paste itself to

the classics lubricants, and lock the

mechanism. The lubrication of chains

must be done with lubricant grease.

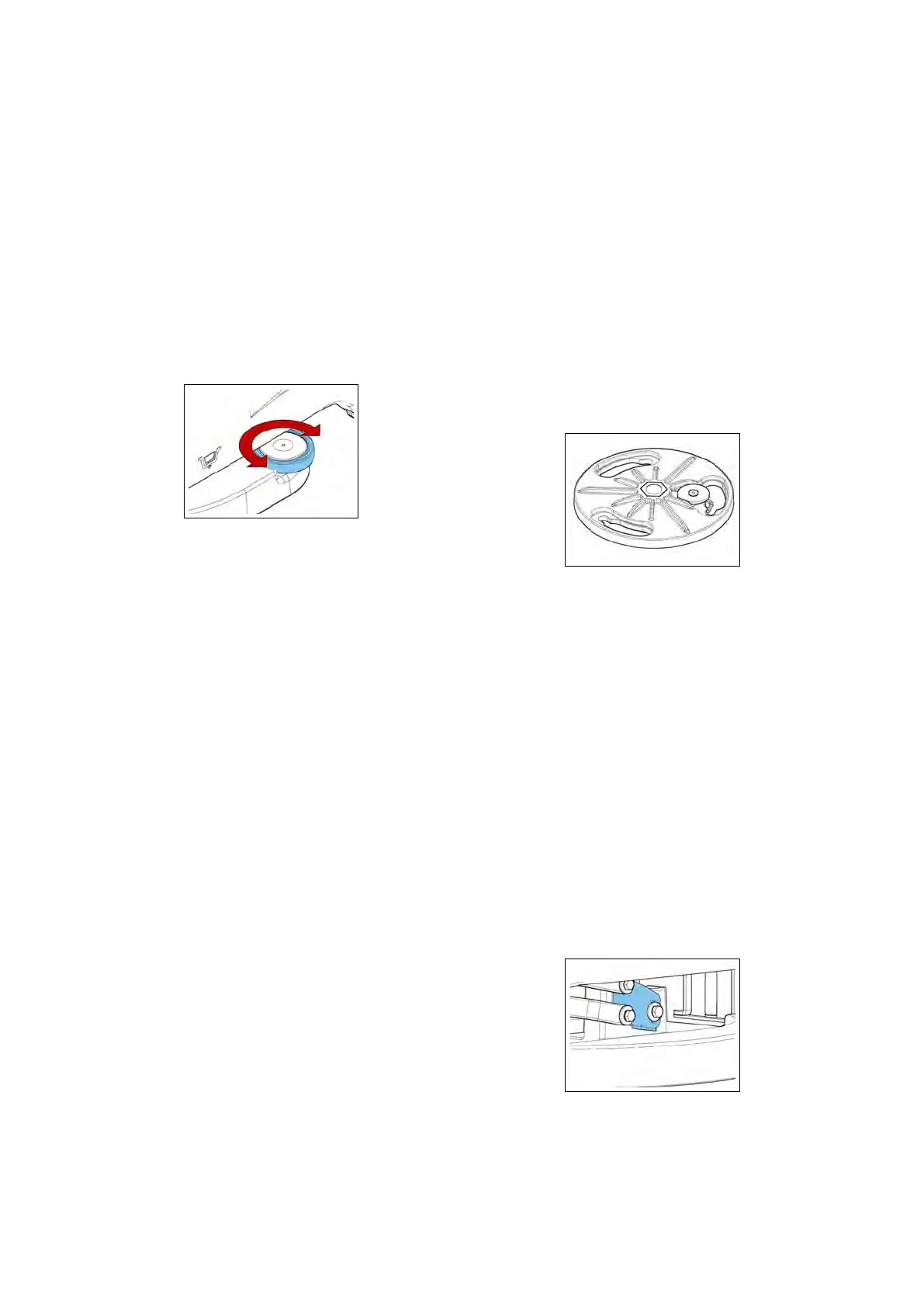

7.4.6 Brush coupling flange

Check (to perform every 150h)

The brush coupling flange is of plastic

material and is not subject to partic-

ular wear. Like the other components

its cleanliness is essential to allow

the brush to engage and disengage

smoothly. ’It is also essential that the

brush locking spring has full function-

ality in order to keep the brush in the

correct position.

If necessary, replace it.

7.4.6-112 Flange

7.4.7 Fixing and adjustment

plate

Check (to perform every 150h)

The fixing plate must be in good condi-

tion, must not show signs of corrosion

or deformation. An incorrect fixing and

adjustment plate does not allow the

entire Mechanical Rubbing group to

work properly.

7.4.7-113 Plate

58

Loading...

Loading...