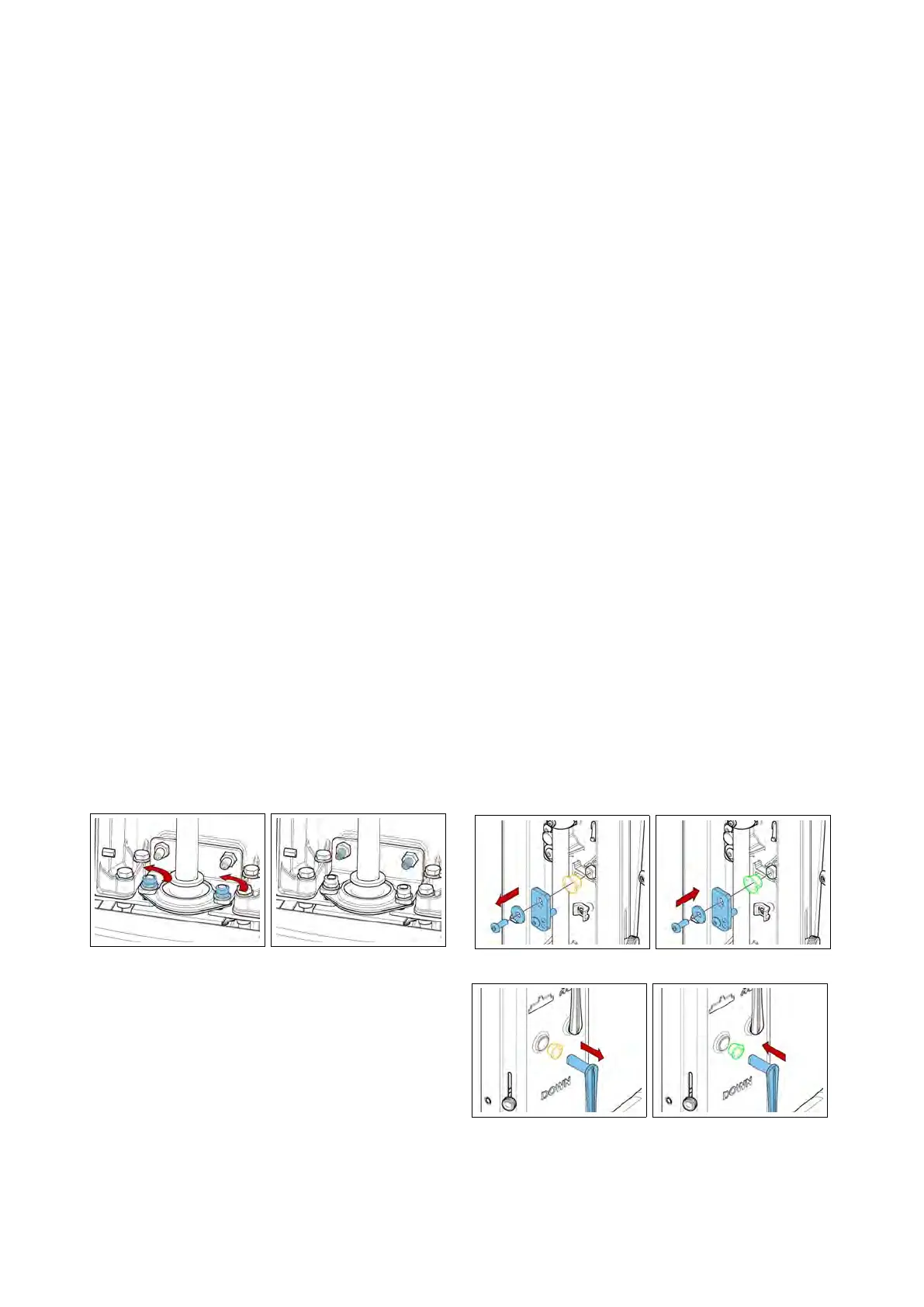

9.3 Adjustments

9.3.1 Steering wheel

The steering wheel should be adjusted

when there is too much clearance be-

tween the chain that acts on the pin-

ion connected to the steering bar of

the steering wheel and the sprocket

mounted on the front wheel.

Procedure

• Put the machine in safe conditions.

• Remove the steering wheel cover.

• Loosen the nuts securing the bottom

support plate of the steering shaft.

• Release the grains locking nuts, set

the optimum tension of the chain by

acting on the grains, lock the adjust-

ment by tightening the locking nuts.

• Once found the optimum tension

retighten the fixing nuts to lock the

bottom supporting plate of the steer-

ing shaft.

• Restore the steering wheel cover.

9.3.1-131 9.3.1-132

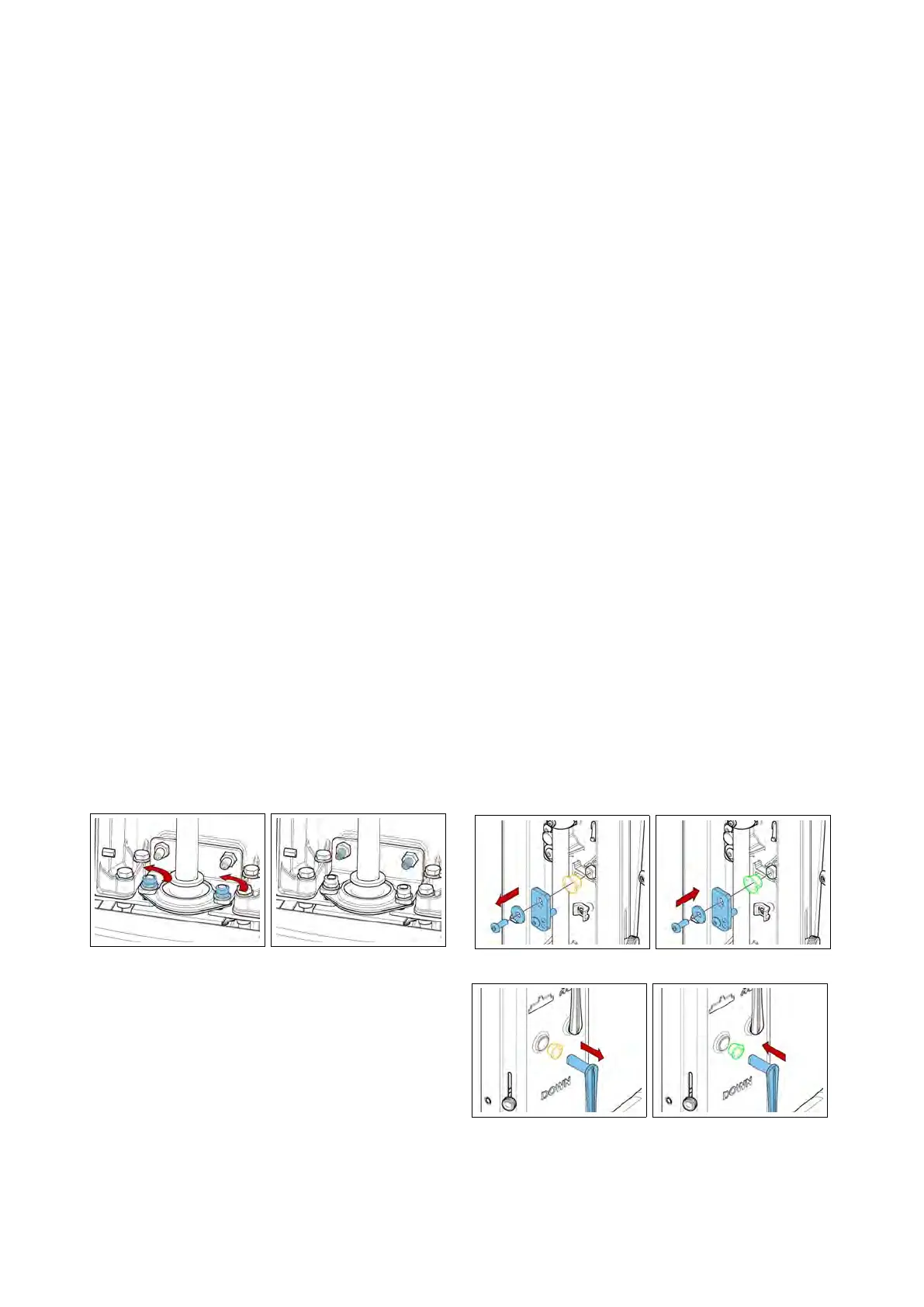

9.4 Maintenance and

Checks

9.4.1 Levers

Check (to perform every 150h)

The operating levers of the squeegee and

the brush deck, must always be oper-

ated with ease and without excessive

effort from the operator.

Maintenance (to perform every 600h)

Replacement of the brass laminated

bushings:

• Put the machine in safe conditions.

• Remove the steering wheel cover.

• Lower the squeegee and the brush

deck to the floor.

• Unscrew the screws that hold the

levers to the steering column and re-

move the internal levers.

• Proceed with the removal of the

bushings and replace them with new

bushings.

• Restore the steering wheel cover.

9.4.1-133 9.4.1-134

9.4.1-135 9.4.1-136

67

Loading...

Loading...