© 2023 Carrier 71

As specified in EN 1643:2014 standard, a valve proving system must be leak-tight such that:

• No single component of a VPS shall have a leak rate greater than 60 cm

3

/hr (0.00212 ft

3

/hr)

for non-integrated double block valves.

• No single component of a VPS shall have a leak rate greater than 120 cm

3

/hr (0.00424 ft

3

/hr)

for integrated or partially integrated double block valves.

As specified in FM 7400 standard, a valve proving system must be leak-tight with a leak rate

no greater than 24in

3

/hr (0.0138 ft

3

/hr, 393 cm

3

/hr)

In certain cases, local codes may require the factoring of the burner capacity in order to derive

the leak rate. For example, it could be specified that the leakage shall not be greater than 0.01%

of burner capacity.

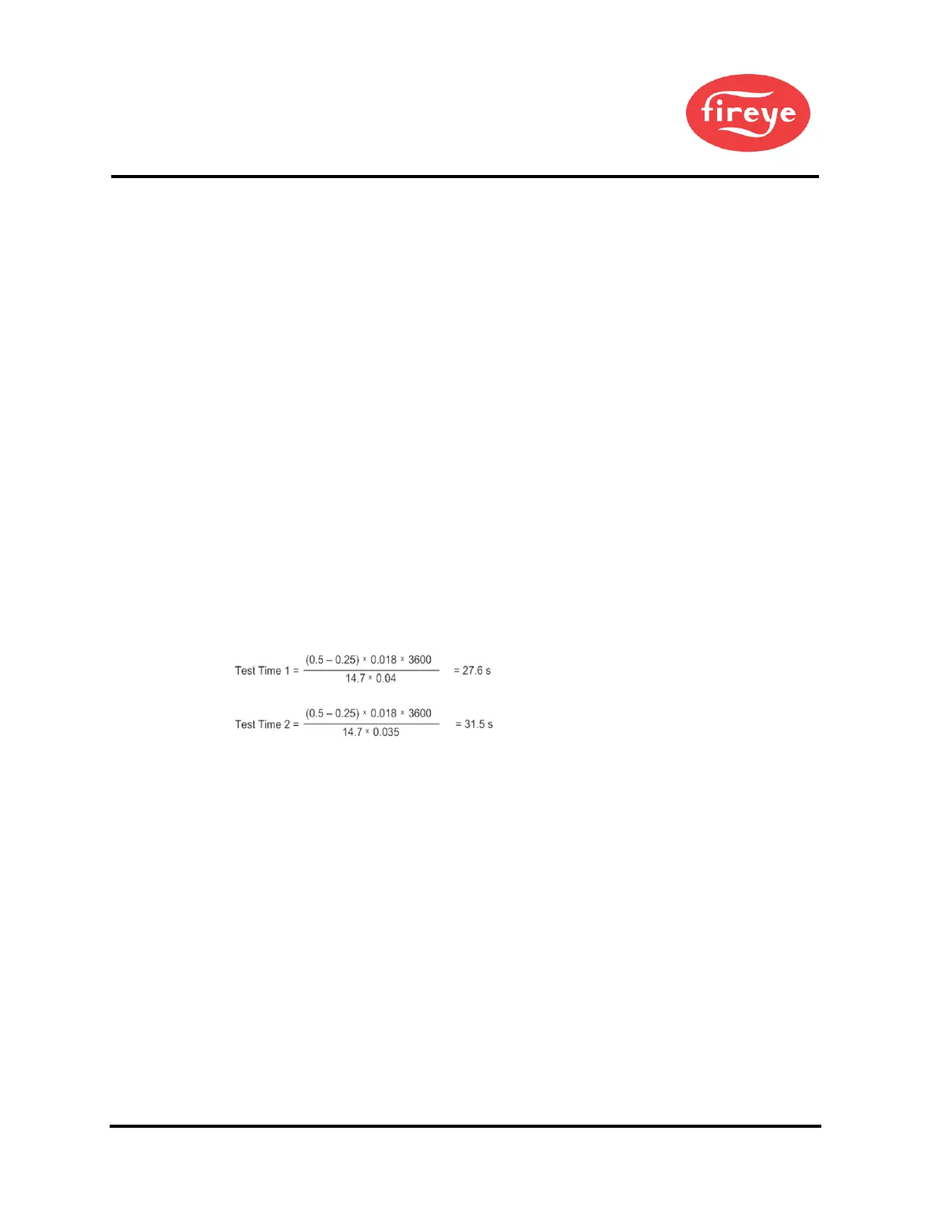

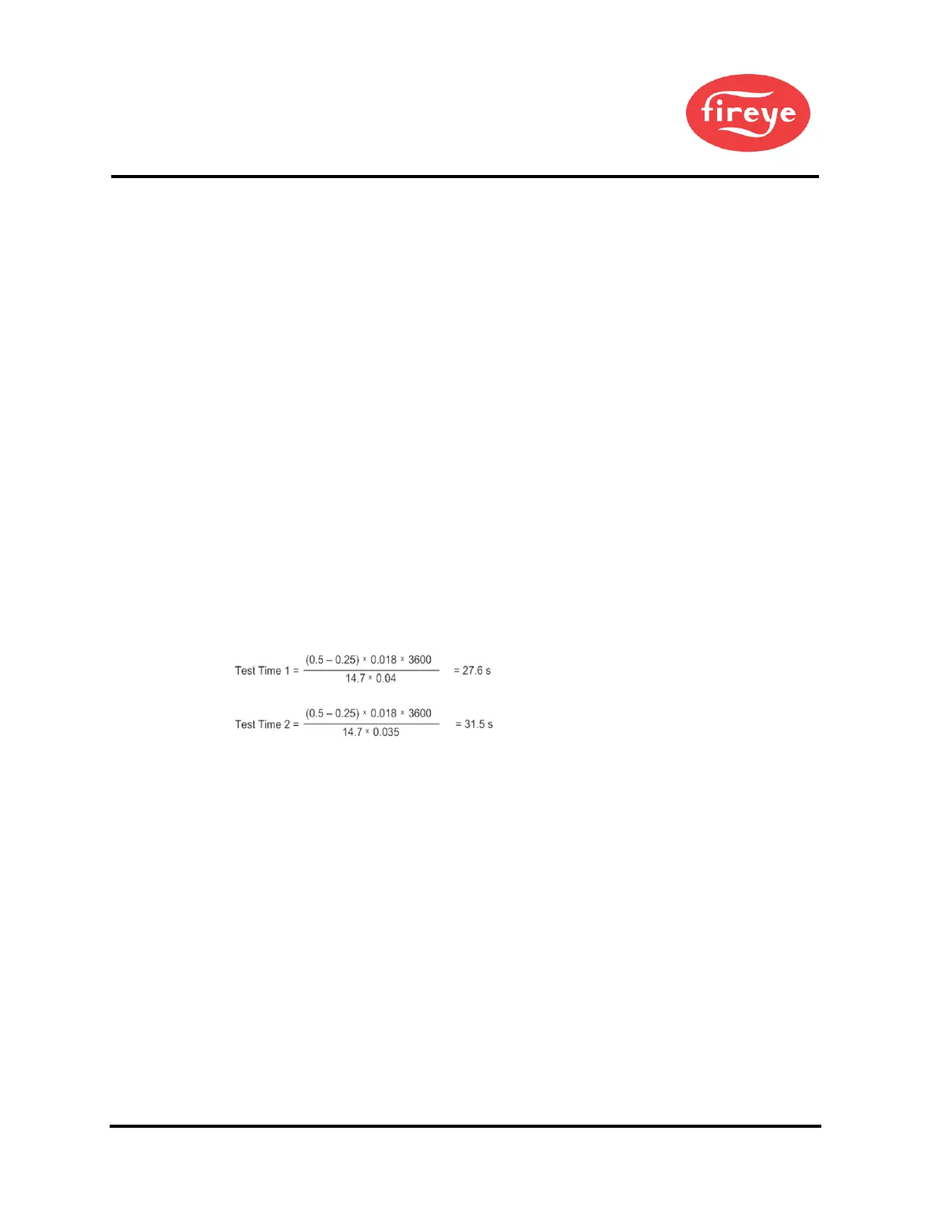

Example of Test Times Calculation:

Assume a valve proving installation with an integrated valve train consisting of total volume of

0.018 ft

3

, and an inlet pressure of 0.5 psi and a permissible leakage rate of 0.04 ft

3

/hr for

upstream valve and 0.035 ft

3

/hr for downstream valve. Assume a single pressure switch is

installed and set to trip at 50% of the inlet pressure. Calculate the expected test times for such

system.

For the example above, round up TEST TIME 1 to 30 seconds and TEST TIME 2 to 35

seconds.

Loading...

Loading...