Instruction Manual

D103412X012

PlantWeb Alerts

July 2013

281

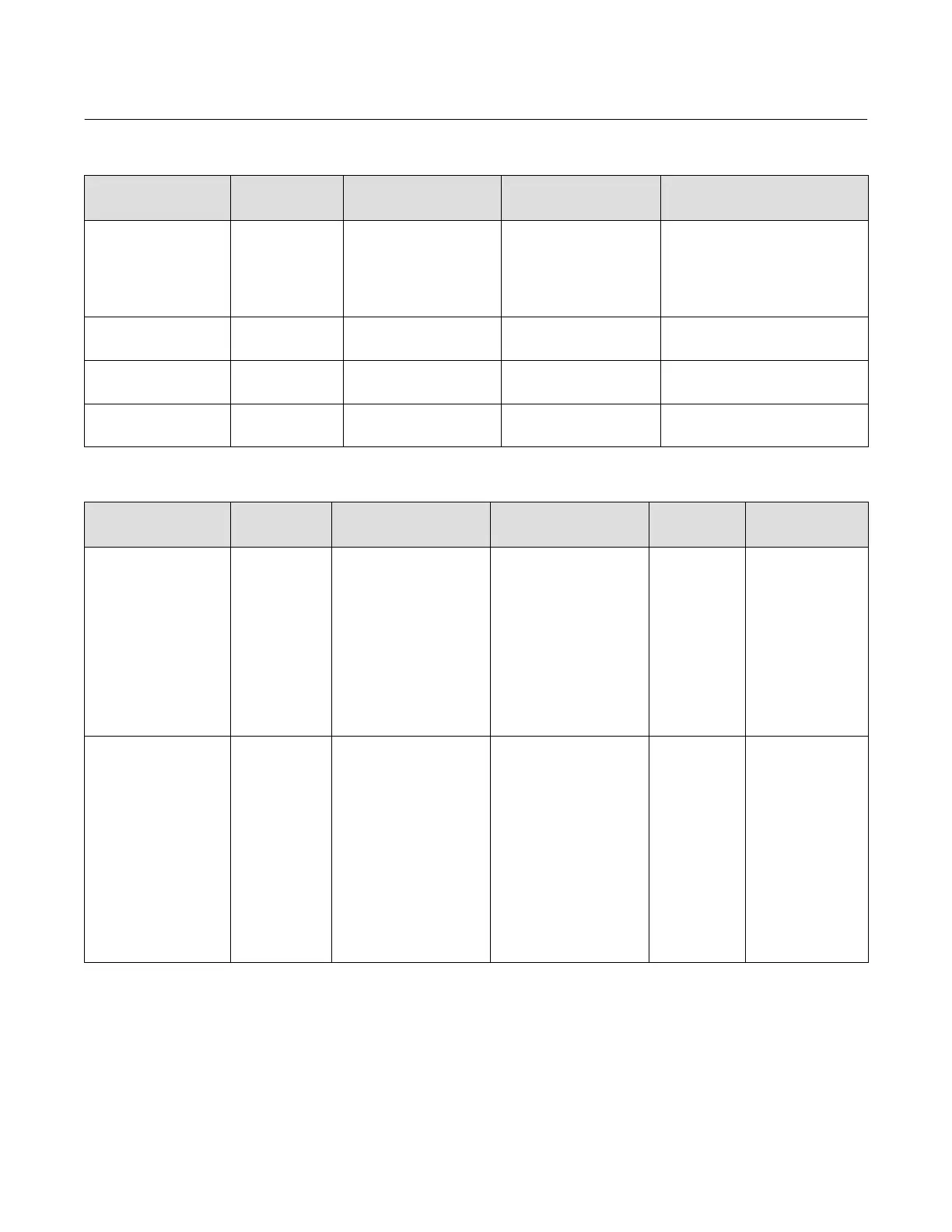

Table C‐2. Setting PlantWeb Alerts (Continued)

PlantWeb Alert

(Group)

(Default Alert Category)

Alert Condition

(Default)

What the Alert is Detecting

Related Parameters

(Default)

Guidelines for Setting

Travel Accumulator

(Travel History)

(Maintenance)

Travel Accumulator

(Disabled)

The accumulated travel has

exceeded the configured limit.

Alert Point (1,000,000)

Deadband (1%)

Packing Bonnets— enable the alert in the

Maintenance Alert Category. When

packing leaks are discovered, set the

Travel Accumulator alert to 90% of the

current Travel Accumulator Value,

triggering an alert prior to anticipated

leak.

Performance Critical

(Performance)

(Failed)

Performance Critical

(Enabled)

Critical performance issues

based on continuous PD tests

internal to the instrument.

None Use default setting

Performance Reduced

(Performance)

(Maintenance)

Performance

Reduced

(Enabled)

Reduced performance issues

based on continuous PD tests

internal to the instrument.

None Use default setting

Performance Information

(Performance)

(Advisory)

Performance

Information

(Enabled)

Performance Information

based on continuous PD tests

internal to the instrument.

None Use default setting

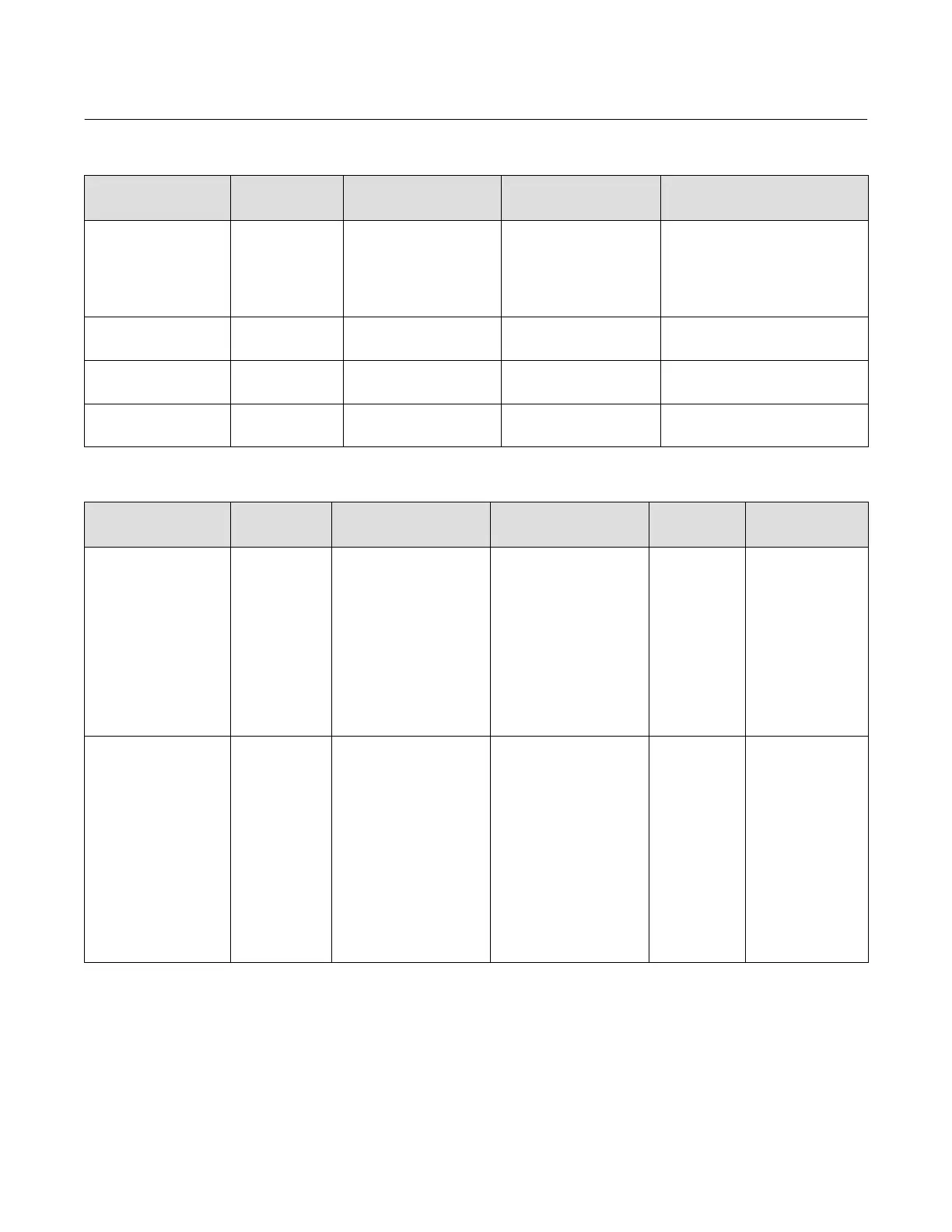

Table C‐3. Using PlantWeb Alerts

PlantWeb Alert

(Group)

(Default Alert Category

Alert Condition

(Default)

What the Alert is Detecting Effect on Valve/Instrument

Recommended

Action

Help

Drive Current

(Electronics)

(Failed)

Drive Current

(Enabled)

The difference between the

expected Drive Current and the

actual Drive Current has

exceeded the Drive Current

Alert Time.

If configured for Self Test

Shutdown, then the transducer

Actual mode is placed Out of

Service until the problem is

fixed. Out of Service results in

the instrument output

pressure(s) and actuator

position being at the Zero

Power Condition.

Check I/P module The instrument has

detected that the

difference between the

expected Drive Current

and the actual Drive

Current is greater than

the configured limit

1) Replace the I/P

module

2) Calibrate the device.

If the problem persists,

replace the printed

wiring board (PWB)

assembly.

Drive Signal

(Electronics)

(Maintenance)

Drive Signal

(Enabled)

If one of the following

conditions exist:

Where Zero Power Condition is

defined as closed:

Drive Signal

< 10% and

Calibrated Travel

> 3%

Drive Signal

> 90% and

Calibrated Travel

< 97%

Where Zero Power Condition is

defined as open:

Drive Signal

< 10% and

Calibrated Travel

< 97%

Drive Signal

> 90% and

Calibrated Travel

> 3%

None - Indicates reduced

performance.

Check instrument

pneumatics

The instrument I/P

drive signal necessary

to generate the

pressure output from

the instrument is not

within the expected

range. Potential causes

include I/P filter

plugged, instrument

pneumatic relay failure,

low supply pressure, air

leaks, or valve sticking.

Test the control valve

assembly for proper

operation. ValveLink

diagnostics can be used

for this purpose.

-Continued-

Loading...

Loading...