3 General principles

FLUXUS H721 3.3 Acoustic penetration

17

UMFLUXUS_H721V1-5EN, 2022-05-15

3.3 Acoustic penetration

The pipe has to be acoustically penetrable at the measuring point. The acoustic penetration is given when pipe and fluid

do not attenuate the sound signal so strongly that it is completely absorbed before reaching the second transducer.

The attenuation caused by the pipe and the fluid depends on:

• kinematic viscosity of the fluid

• proportion of gas bubbles and solid particles in the fluid

• deposits on the inner pipe wall

• pipe material

The following requirements have to be met at the measuring point:

• pipe always completely filled

• no deposits of solid particles in the pipe

• no formation of gas bubbles

Observe the following notes on the selection of the measuring point:

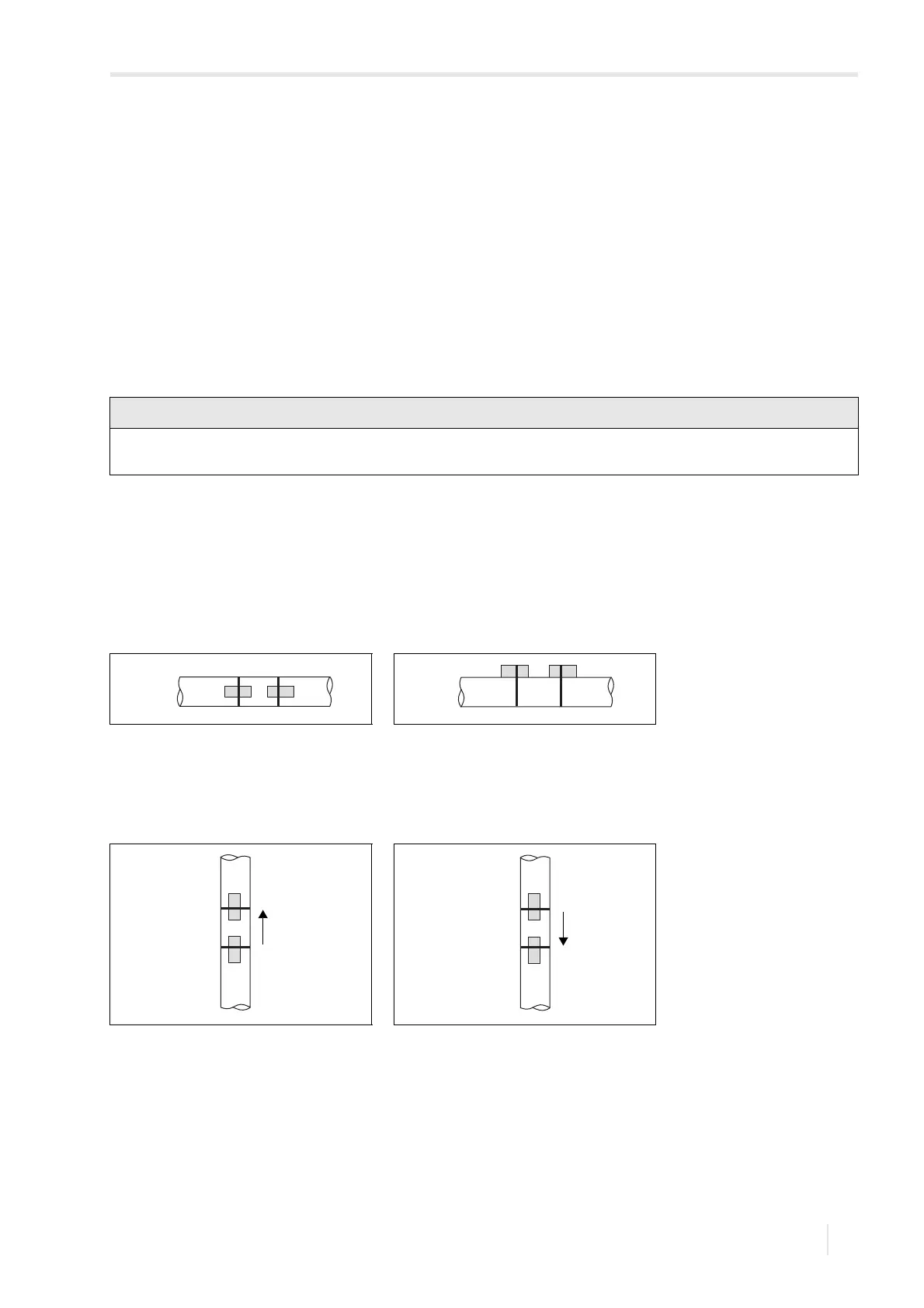

Horizontal pipe

Select a measuring point where the transducers can be mounted laterally on the pipe, allowing the sound waves to

propagate horizontally in the pipe. Thus, solid particles on the bottom of the pipe or gas bubbles in the upper part are

prevented from influencing the propagation of the signal.

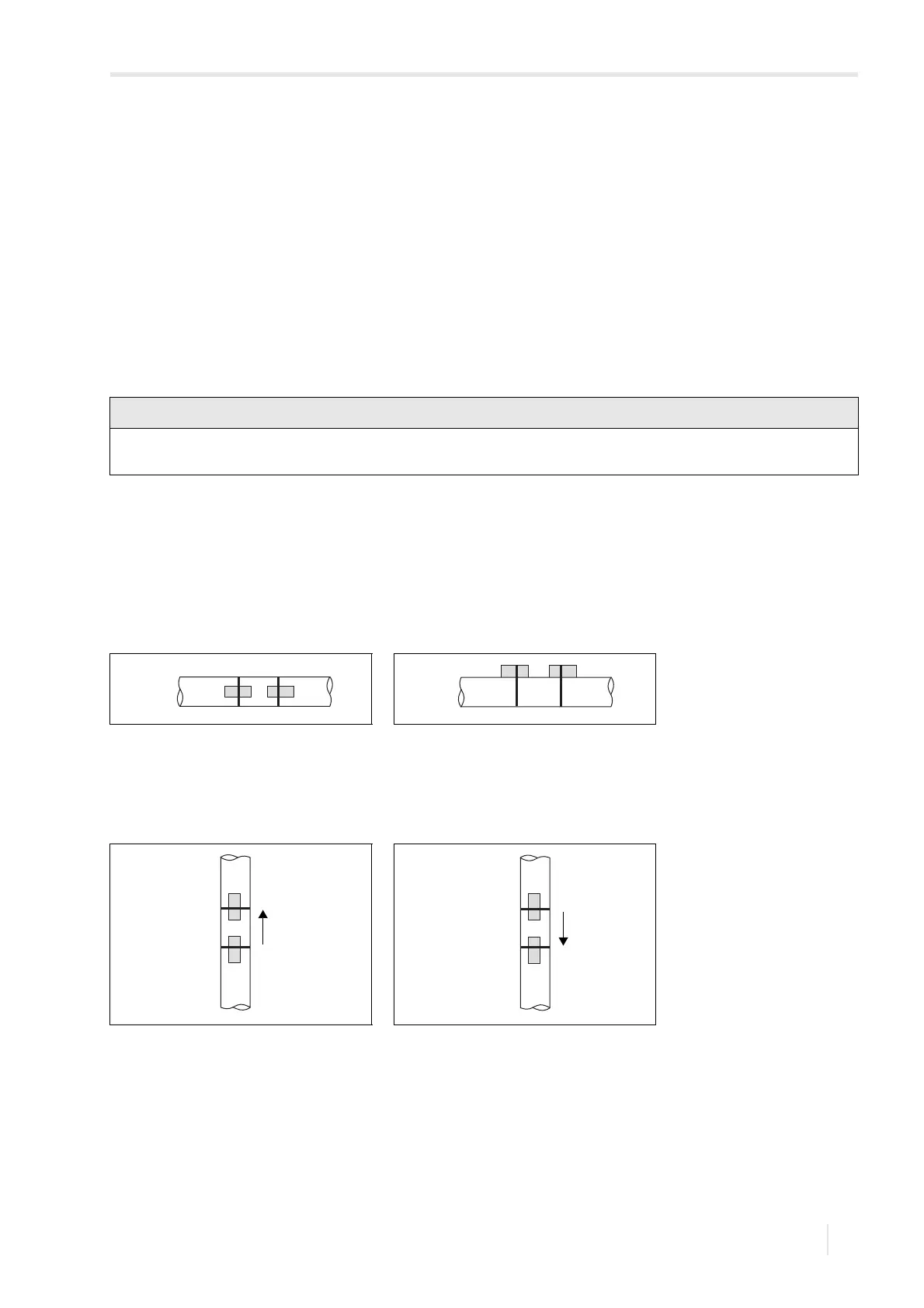

Vertical pipe

Select the measuring point at a pipe section where the fluid flows upward. The pipe has to be completely filled.

Even bubble-free fluids can form gas bubbles when the fluid expands, e.g., before pumps and after great cross-

section extensions.

Fig. 3.10: Recommended transducer

mounting position (laterally)

Fig. 3.11: Disadvantageous transducer

mounting position (on top)

Fig. 3.12: Recommended transducer

mounting position

Fig. 3.13: Disadvantageous transducer

mounting position

Loading...

Loading...