RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 13

ELECTRICAL

NOTE: Before proceeding with electrical installation, read

the instructions in the section “Proper Installation of

Electronic Equipment in an Industrial Environment”.

RXB PLUS units are supplied with a SBC (single-board com-

puter) microprocessor control system. Care must be taken

that the controls are not exposed to physical damage dur-

ing handling, storage, and installation. The microprocessor

enclosure cover must be kept tightly closed to prevent entry

of moisture and foreign matter.

Customer-control power connec-

tions are made at the BOTTOM of

the microprocessor enclosure.

Consult local ordinances before installation. Current

transformer wiring should be kept separate. Extreme

care should be taken that metal filings or other foreign

material is not left in the microprocessor enclosure. Use

seal-tight conduit fittings to prevent moisture entry into

the microprocessor enclosure. This is the ONLY electri-

cal enclosure that should be opened during installation

and it should be kept tightly closed whenever work is

not being performed in it.

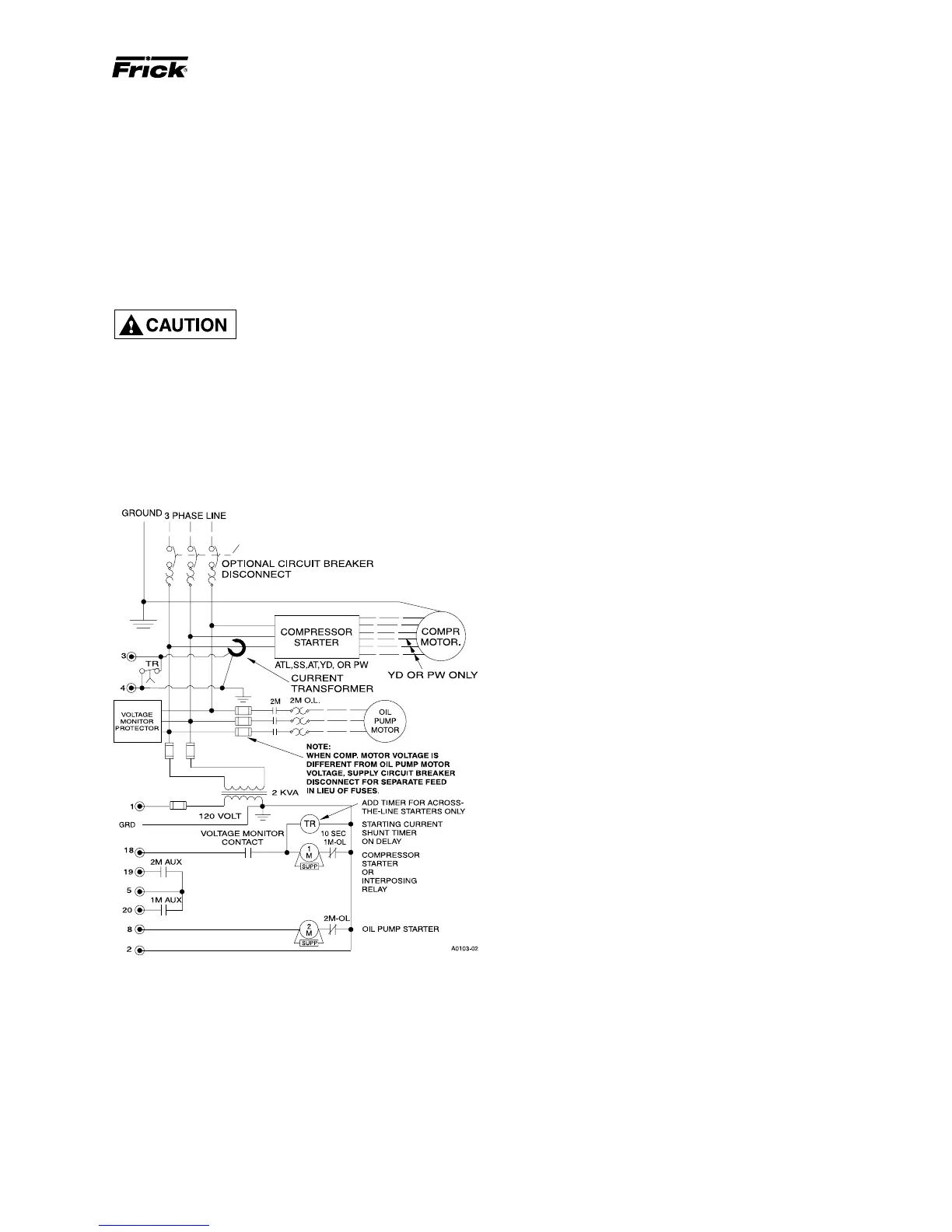

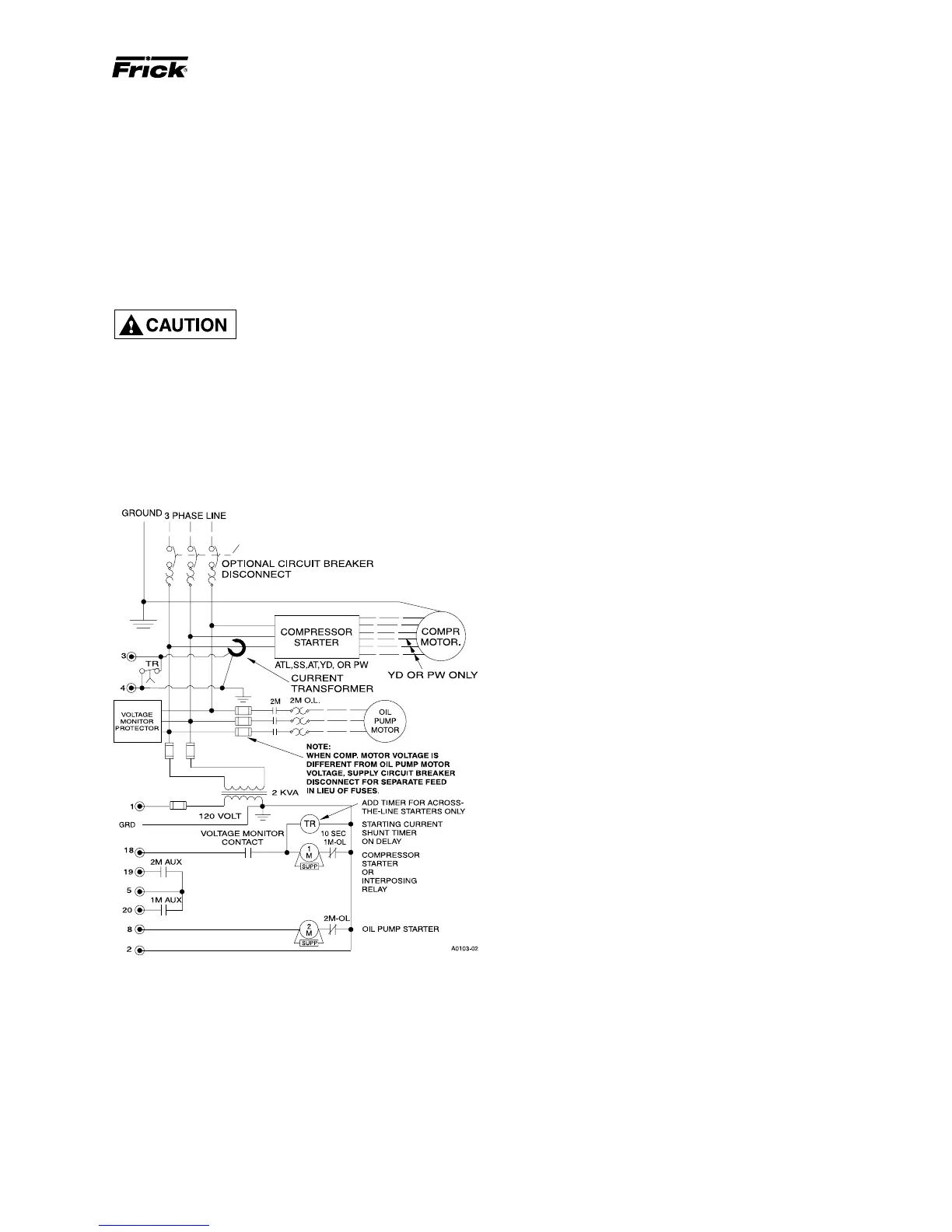

1. The compressor motor starter of the specified HP and

voltage for the starting method specified (across-the-line,

autotransformer, wye-delta, or solid state).

NOTE: If starting methods other than across-the-line are

desired, a motor/compressor torque analysis must be

done to ensure that sufficient starting torque is avail-

able, particularly in booster applications. Contact FRICK

Company if assistance is required.

2. If specified, the starter package can be supplied as a

combination starter with circuit breaker disconnect. Howev-

er, the motor overcurrent protection/disconnection device

can be supplied by others, usually as a part of an electrical

power distribution board.

3. A 2.0 KVA control power transformer (CPT), to supply

120 volt control power to the control system and separator

oil heaters, is included. If environmental conditions require

more than a 500 watt oil heater, an appropriately oversized

control transformer will be required.

4. One (1) normally open, compressor-motor-starter auxil-

iary contact and 1 normally open, oil-pump-motor-starter

auxiliary contact (opt.) should be supplied and wired as

shown on the starter package wiring diagram. In addition,

the compressor and oil pump motor starter (opt.) coils and

the CPT secondaries should be wired as shown on starter

package wiring diagram.

5. The compressor motor Current Transformer (CT) can be

installed on any one phase of the compressor leads. NOTE:

The CT must see all the current on any one phase; there-

fore in wye-delta applications, BOTH leads of any one

phase must pass through the CT.

6. Oil Pump Option: If the optional oil pump is specified, an

oil pump starter must be a component of the unit starter

package. The pump starter should be equipped with fuses

or, in the case where the compressor motor is a different

voltage from the oil pump motor, a circuit breaker discon-

nect suitable for separate power feed.

NOTE: Do not install a compressor HAND/OFF/AUTO

switch in the starter package as this would bypass the

compressor safety devices.

INSTALLATION

MOTOR STARTER PACKAGE

Motor starter and interlock wiring requirements are shown

in the wiring diagram, above. All the equipment shown is

supplied by the installer unless a starter package is pur-

chased from Frick . Starter packages should consist of:

NOTE: When compressor motor voltage is different from

oil pump motor voltage, supply a circuit breaker discon-

nect for separate feed in lieu of fuses.

NOTE: Customer ground required, see Micro Panel As-

sembly Wiring Diagram.

Loading...

Loading...