RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 26

OPERATION

AT 158

O

F.

The microprocessor triggers the High Oil Temperature Alarm

and displays the alarm on the Operating display and the

Annunciator display.

AT 167

O

F.

The microprocessor instructs the compressor motor to shut

down and displays a CUTOUT indication on the Operating

display. It stores the operating conditions at the moment of

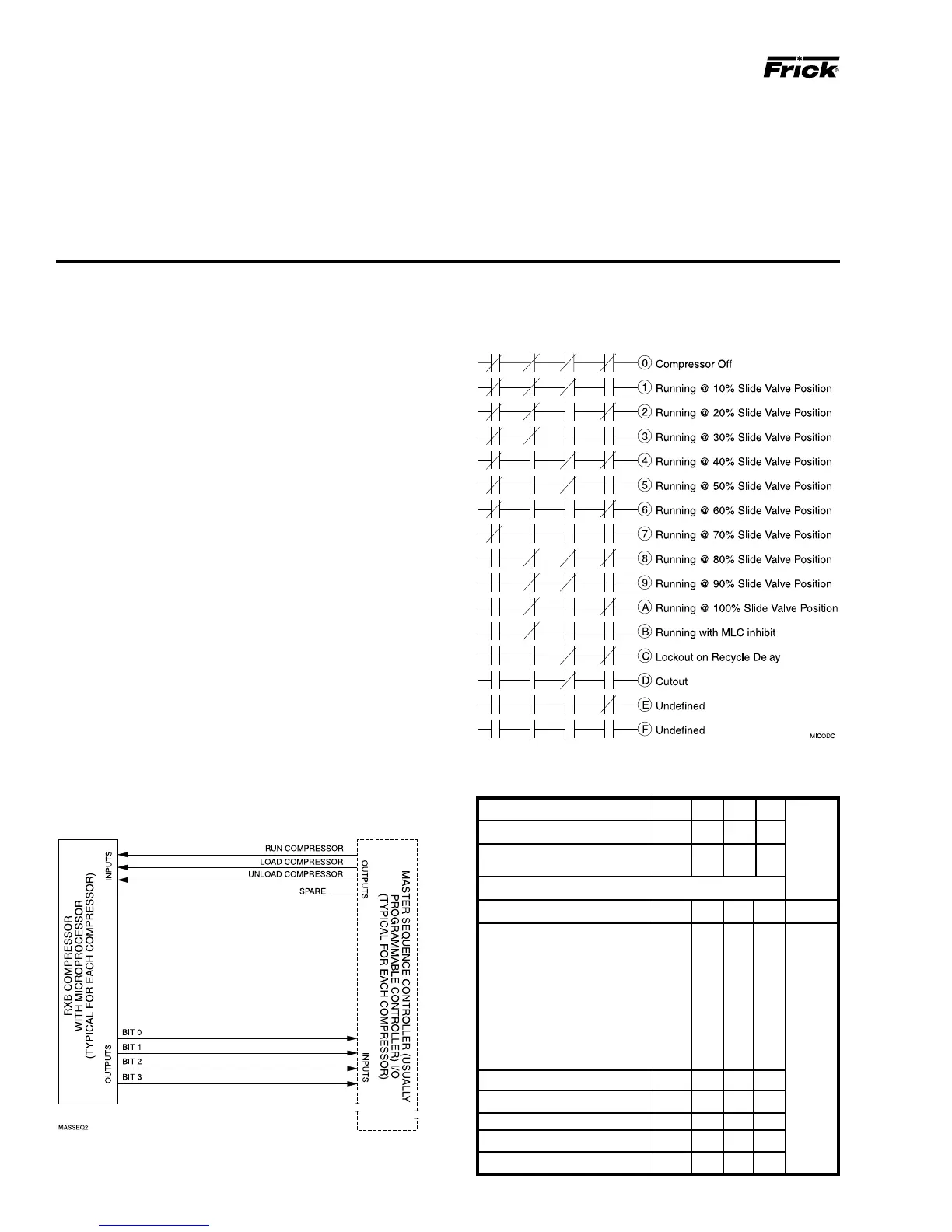

OUTPUT NO.

TERMINAL NO.

MNEMONIC

Compressor Off

Running

Slide

Valve

Position

HEX

CODES

13

34

BIT

0

0

1

0

1

0

1

0

1

0

1

0

33

14

BIT

1

0

15

32

BIT

2

0

16

31

BIT

3

0

MEANING OUTPUT DATA CODE

Running with MLC Inhibit

Lockout on Recycle Delay

Cutout

Undefined

Undefined

1101

0011

1011

0111

1111

B

C

D

E

F

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

1

1

1

0

1

1

0

0

1

1

0

0

1

1

2

3

4

5

6

7

8

9

A

cutout in the Freeze display. Information regarding the cut-

out will also be retained by the Annunciator and the Shut-

down Record displays.

NOTE: If the operator makes an error by attempting to

start the compressor under conditions outside safe

normal operating conditions, the microprocessor will

prevent start-up and advise the operator of the fault.

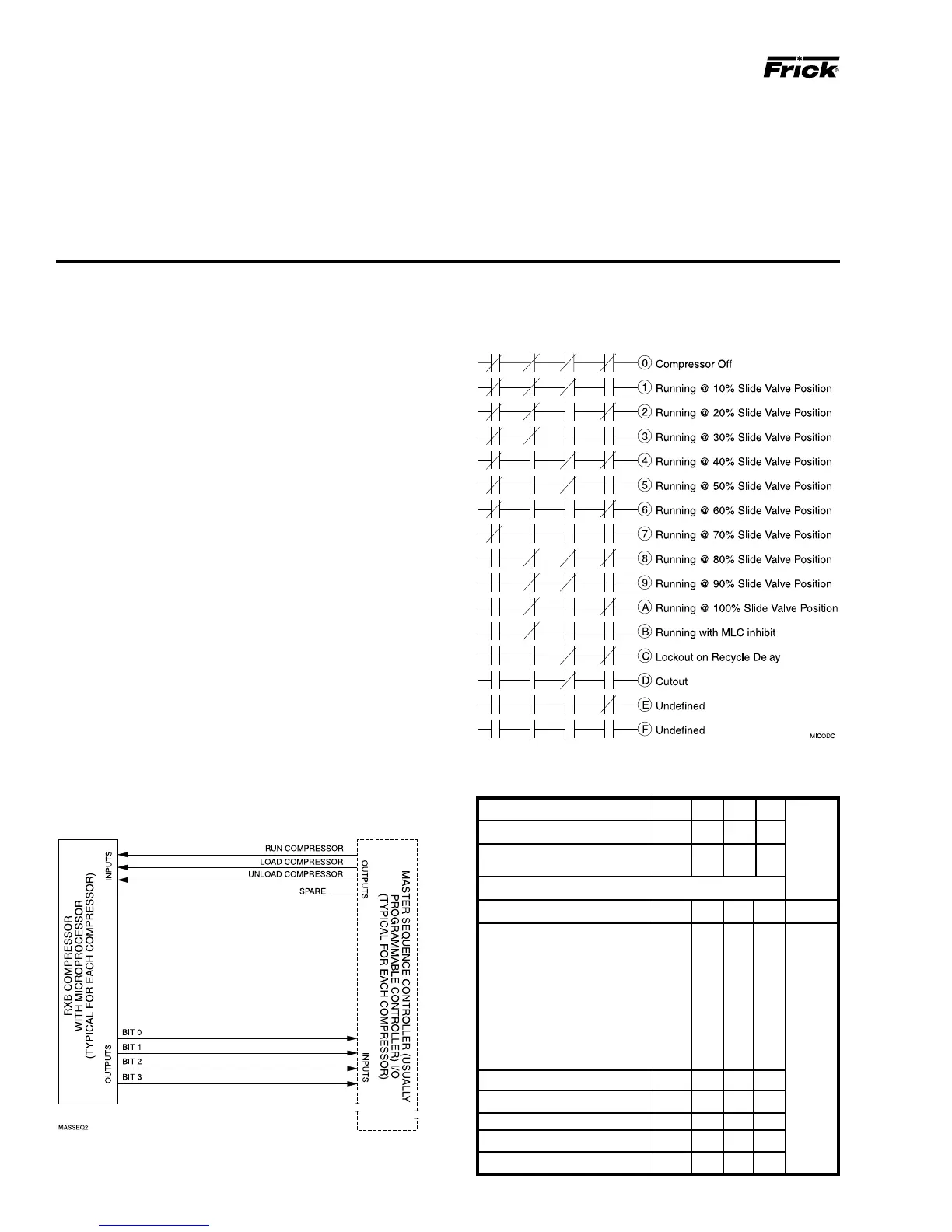

MULTIPLE COMPRESSOR SEQUENCING

FOR RXB COMPRESSOR UNITS WITH

MICROPROCESSOR CONTROLS

A - The standard microprocessor panel includes:

1. Remote Run Input

2. Remote Load Input

3. Remote Unload Input

The remote run input is only recognized when the remote

run mode has been selected by pressing the [REMOTE

START] key on the front panel of the microprocessor.

The remote load and unload inputs can only be recognized

when the [REMOTE] key in the slide valve column on the

front panel of the microprocessor has been pressed.

B - If master sequencing between multiple compressors in

parallel on a common suction is desired. This output data

will permit the compressor microprocessor to be interfaced

with a master sequence controller. See electrical diagram

for details.

C - A master sequence controller must be installed to pro-

vide the signals to remote start and stop the compressors

and remote load and unload the compressors based on the

common suction pressure or other parameter and the com-

pressor status based on the optional microprocessor out-

put data feedback. The customer may supply his own mas-

ter sequencer panel (usually a programmable controller) or

Frick, can supply this sequencer if desired (contact Frick

Company for pricing).

SUGGESTED PROGRAMMABLE

CONTROLLER PROGRAM TO DECODE

MICROPROCESSOR OUTPUT DATA CODES

Loading...

Loading...